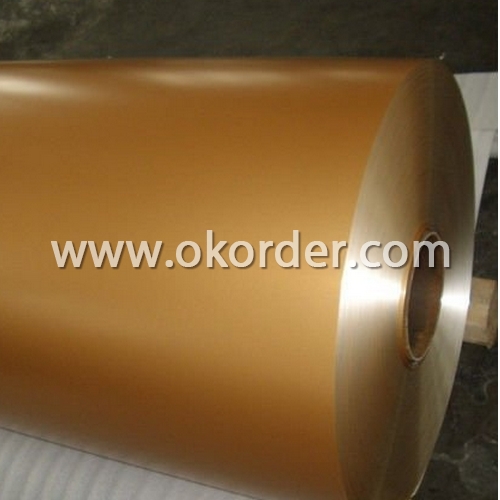

1050 Aluminum Sheet Coil with Anti-Scratch Coating

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.General Information of anti-scratch coated aluminium coil/sheet:

Anti-scratch Coated aluminum coil is between 0.10 mm and 4.00mm in thickness with PVDF, PE. Color is according to RAL colors or customer's sample. The coated aluminum coil/sheet has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

2.Features of anti-scratch coated aluminium coil/sheet:

CNBM produces aluminum coils which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3.The main producing procedure of anti-scratch coated aluminium coil/sheet:

Rolling--Annealing--Slitting—Rinsing—Coating—Baking---Coiling

4. Specification of anti-scratch coated aluminium coil/sheet

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2200mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

coated aluminium, coated aluminiumcoil,pvdf coated aluminium panel,pe coated aluminium sheet,composite aluminium panel,roller coating aluminium sheet,

Alloy:1050/1060/1070/1100/1200/3003/3004/3104/5052/5754/5083/8011. Temper:O/H12/H14/H16/H18/H19/H22/H24/H26. Thickness:0.006-8mm. pvdf roller coating/coated aluminium coil/sheet can suit for large area house and wall decoration when finished by cut and punch further processing. Rolling coating coil for ceiling and roofing includes PVDF series/nanometer series/pearly luster series/self clean series/anti scratch series and wood grain series for different ceiling/roofing/house decorative and lamp decoration.

taking samples from the real wood and marble stone and with supreme coating technology,our wood/marble rolling will show you elegant,tridimensional and clear texture,be of easy clean,weather resistance,environment friendly high strength,which the real wood and marble can not reach. The wood/marble coils are especially suitable for project,house and indoor high pressure decoration.

- Q: What is the creep resistance of aluminum coils?

- The creep resistance of aluminum coils is generally high, as aluminum has a low melting point and exhibits minimal creep deformation under normal operating conditions.

- Q: This question seeks to understand the various types of aluminum coils that are commonly found in the market.

- <p>Aluminum coils available on the market today can be categorized based on their properties and applications. These include: 1. Plain Aluminum Coils: Used for general purposes like packaging and construction. 2. Embossed Aluminum Coils: Feature a textured surface, used in decorative applications. 3. Alloy Aluminum Coils: Made from a mixture of aluminum and other metals for enhanced strength or corrosion resistance. 4. Color Coated Aluminum Coils: Coated with paint or plastic for aesthetic or protective purposes. 5. Heat Treated Aluminum Coils: Processed to improve their mechanical properties. 6. Mirror Finish Aluminum Coils: Have a highly reflective, polished surface. 7. Pre-painted Aluminum Coils: Coated with a layer of paint before being used in construction or other applications. Each type serves specific industries and applications, with variations in thickness, width, and alloy composition.</p>

- Q: Are there any specific guidelines for the handling of aluminum coils?

- Yes, there are specific guidelines for the handling of aluminum coils. These guidelines typically include proper lifting techniques, the use of appropriate equipment such as cranes or forklifts, and ensuring that the coils are stored in a clean and dry environment to prevent corrosion. It is also important to handle the coils gently to avoid any damage or deformation.

- Q: What are the standard dimensions for aluminum coils?

- The dimensions of aluminum coils can vary depending on their intended use and the industry they are being used in. However, there are generally accepted standard dimensions for aluminum coils. In terms of width, aluminum coils can range from 4 inches (10 cm) to 60 inches (152 cm). The exact width will depend on factors such as the purpose of the coils, the manufacturing process, and the customer's specifications. When it comes to thickness, aluminum coils are available in various gauges or millimeters. Common thicknesses can range from 0.018 inches (0.46 mm) to 0.25 inches (6.35 mm) or even thicker in certain applications. The length of aluminum coils can also vary based on customer requirements or industry standards. Coils can be supplied in standard lengths, such as 1000 feet (304.8 meters) or 2000 feet (609.6 meters), or they can be custom-cut to a specific length. It is important to note that these dimensions are not fixed and can be customized to suit the needs of a particular project. Different industries, like construction, automotive, and aerospace, may have their own specific size requirements for aluminum coils. Therefore, it is recommended to consult with an aluminum coil manufacturer or supplier to determine the most appropriate dimensions for a specific application or project.

- Q: This question asks about the suitability of aluminum coils for outdoor applications based on their weight and strength.

- <p>Yes, aluminum coils are lightweight and strong, making them suitable for outdoor use. Aluminum is known for its high strength-to-weight ratio, which means it can withstand significant stress without adding much weight. It also has excellent corrosion resistance, which is crucial for outdoor applications where exposure to weather elements can lead to degradation. Additionally, aluminum's malleability allows it to be easily shaped and formed into various configurations for different outdoor structures and applications. Its light weight also reduces the load on structures, which can be an advantage in many construction scenarios.</p>

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for HVAC ductwork. It offers excellent heat transfer properties and is commonly used in both residential and commercial HVAC systems.

- Q: What specific features or properties define aluminum coil?

- <p>Aluminum coil is characterized by its lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. It is non-magnetic, has good thermal and electrical conductivity, and is highly malleable and ductile, making it easy to form into various shapes. Aluminum coil also has a shiny, reflective surface and is recyclable. It is commonly used in construction, automotive, packaging, and electrical applications due to these properties.</p>

- Q: Are aluminum coils suitable for food and beverage packaging?

- Food and beverage packaging can indeed utilize aluminum coils. Aluminum, being a versatile material, offers numerous advantages for packaging purposes. Its lightweight nature makes transportation and handling a breeze. Furthermore, its exceptional resistance to corrosion ensures that the packaging remains intact, safeguarding the contents from external elements. Additionally, aluminum boasts excellent thermal conductivity, enabling efficient heat transfer, which proves advantageous for temperature-sensitive food and beverage items. Moreover, it acts as a formidable barrier, impermeable to light, moisture, and oxygen, thereby maintaining the quality and freshness of the packaged goods. Furthermore, aluminum's recyclability and reusability make it an environmentally friendly choice for packaging. Consequently, aluminum coils emerge as a dependable and fitting option for food and beverage packaging, courtesy of their durability, protective properties, and sustainability.

- Q: I am concerned about the environment so I collect empty aluminum cans off the street when I walk my dog. Right now I have 3 large garbage bags full of crushed aluminum can. The problem is... some of the cans have dirt on and in them. Some of thoroughly flattened ones may even have small pebbles embedded in them. Will these be accepted at the recycling facility? I'm guessing it doesn't matter because when they melt them any organic materials will burn away and any dirt particles or small pebbles will be separated from the molten aluminum. What do you think?

- The dirt won't be a problem, normally. The pebbles might, but I haven't heard any mention of this being a problem. Add: Aluminum melts at around 960 F, while most rocks won't. By that time, the dried up sugars and cigarette butts will have all burned off. You can melt aluminum in a cast iron frying pan, but I really don't recommend trying that: If a drop of water hits the molten aluminum it'll expand somewhere around 1700 times it's original volume, nearly instantly. This will be like a small bomb going off, and molten aluminum will spray all over. That's quite dangerous, even if you do have protective gear.

- Q: This question asks about the impact of aluminum coils on food quality, considering possible effects on taste, safety, and preservation.

- <p>Aluminum coils, when used in cooking or food packaging, can potentially affect the quality of food. If aluminum leaches into the food, it may alter the taste and could pose health risks due to aluminum's neurotoxic properties. However, modern food-grade aluminum coils are coated or anodized to prevent such leaching, ensuring food safety. They are also used in heat transfer for cooking, which can improve the efficiency and evenness of cooking, thus enhancing food quality. It's crucial to use high-quality, food-safe aluminum coils to avoid any negative impact on food quality and safety.</p>

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

1050 Aluminum Sheet Coil with Anti-Scratch Coating

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords