1.50mm HDPE Pond Liner for Water/Pond/Landfill - Geotextil Poliéster

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.50mm HDPE Pond Liner for Water/ Pond/ Landfill

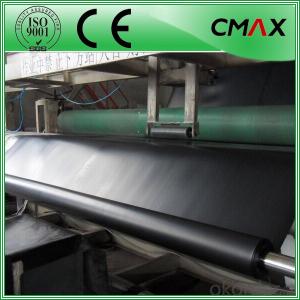

Geomembrane Features:

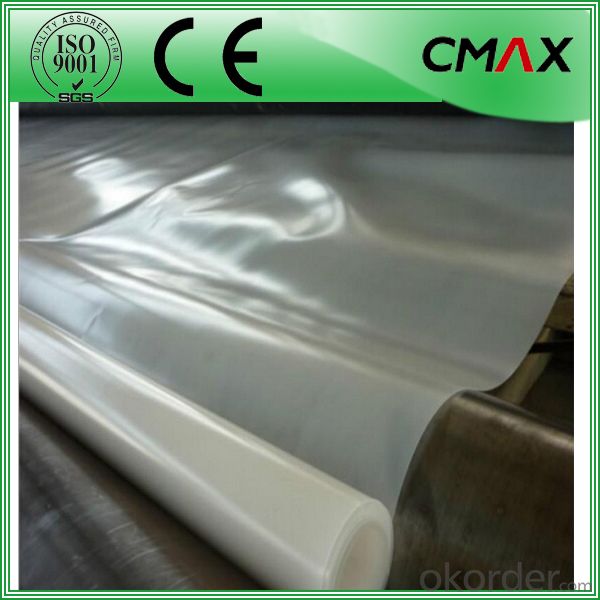

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

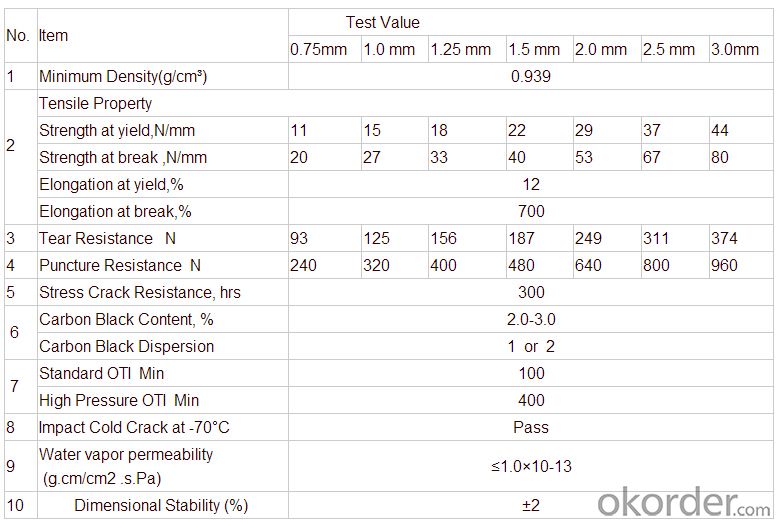

Specifications and Technical datas:

| Thickness | 0.15mm - 4.0mm |

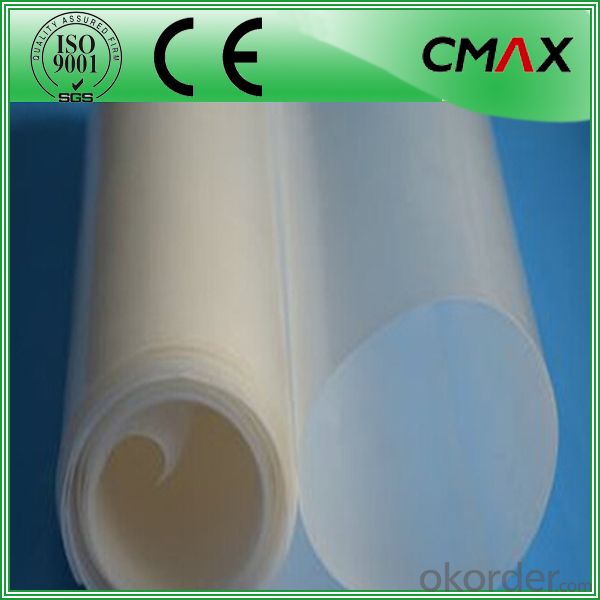

| width | Within 8 m |

| length | 50-100m/roll (at request) |

| Material | HDPE,( LDPE, LLDPE, PVC, EVA ) |

| Color | Black , white , grey |

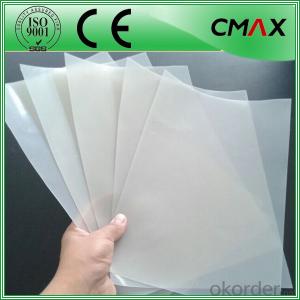

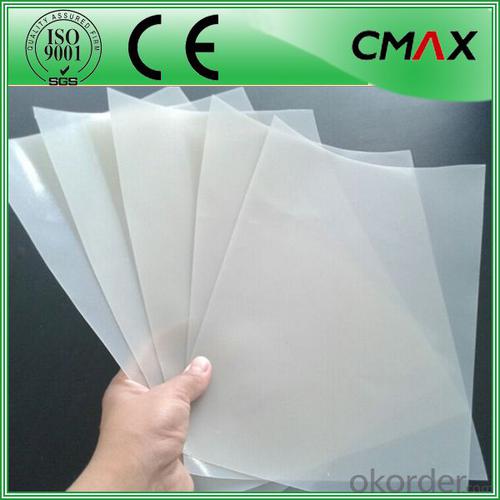

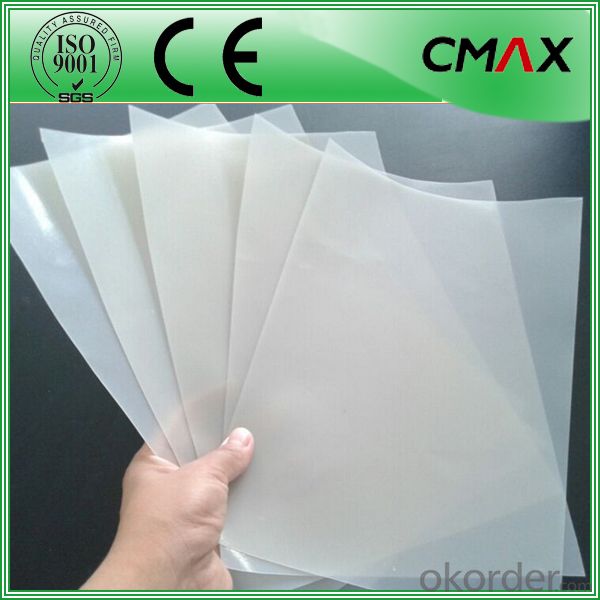

| Optional surface | Textued(one or two side) or smooth surface |

| Manufacturer | The biggest geomembrane liner manufacturer/factory in China for many years |

Details of our products:

Applications:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help in stabilizing embankments?

- Geotextiles help in stabilizing embankments by providing reinforcement and erosion control. They are placed within the soil layers, acting as a barrier to prevent soil movement and promote stability. The geotextiles increase the shear strength of the soil, reducing the risk of slope failure. Additionally, they allow for water drainage while preventing the loss of fine particles, therefore minimizing erosion and maintaining the integrity of the embankment.

- Q: How do geotextiles prevent soil contamination?

- Geotextiles prevent soil contamination by acting as a barrier between the soil and any potentially harmful substances. They are designed to allow water to pass through while filtering out pollutants, preventing them from entering and contaminating the soil. Additionally, geotextiles can also help to stabilize the soil and prevent erosion, reducing the risk of contamination from soil displacement.

- Q: What are the factors that affect the effectiveness of geotextiles in erosion control?

- The factors that affect the effectiveness of geotextiles in erosion control include the type and quality of the geotextile material, the installation method and technique, the slope gradient and soil conditions, the presence of vegetation, and the level of maintenance and monitoring.

- Q: How do geotextiles help in preventing shoreline erosion?

- Geotextiles help in preventing shoreline erosion by acting as a barrier that stabilizes the soil and prevents erosion caused by waves and currents. They are placed along the shoreline to trap sediment and prevent it from being washed away, thus preserving the integrity of the shoreline.

- Q: How do geotextiles enhance the performance of retaining walls?

- Geotextiles enhance the performance of retaining walls by acting as a barrier against soil erosion and providing additional stability. These textile materials are placed between the soil and the retaining wall, preventing the loss of fine particles and promoting proper drainage. Geotextiles also distribute the weight of the soil more evenly, reducing the likelihood of structural failure and enhancing the overall durability of the retaining wall.

- Q: Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. They are commonly used to provide soil reinforcement, erosion control, and drainage in various underground applications such as tunnels, basements, and underground storage facilities. Geotextiles can help improve soil stability, prevent soil erosion, and enhance the overall performance of the underground construction project.

- Q: How do geotextiles aid in the protection of geomembranes?

- Geotextiles aid in the protection of geomembranes by acting as a protective barrier between the geomembrane and the surrounding soil or other materials. They prevent direct contact and potential damage from sharp objects, rocks, or roots, while allowing for the drainage of water and gases. This helps to extend the lifespan of the geomembrane and maintain its integrity, ensuring effective containment and protection in various applications such as landfills, ponds, or construction projects.

- Q: Polyester filament geotextile performance characteristics

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: I would like to make the beach bigger along the lake in our backyard. I am hoping to do it myself for my husband for father's day. I need suggestions on the best way to do this as a one women team.

- Geotextile Landscape Fabric

- Q: Geotextile construction inspection batch ye do?

- Plastic woven category: the same formula, the same specifications of 100,000 square meters of products for a group; less than 100,000 square meters, the actual number of a batch. Non-woven geotextiles: the same frequency of production of the same specifications for a number of products; batch volume can be accumulated 100 volumes for a group, but the week is still less than 100 volumes of output, then with a group of output. Plastic woven cloth: batch as a unit, each batch of products randomly take 3 volumes as a sample geotextile categories: each batch of products randomly selected 2% to 3%, but not less than 2 volumes. Sample requirements: the whole width, length 3m or more, the sample can be rolled up, but can not be folded.

Send your message to us

1.50mm HDPE Pond Liner for Water/Pond/Landfill - Geotextil Poliéster

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords