cold rolled stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless Steel round Bar

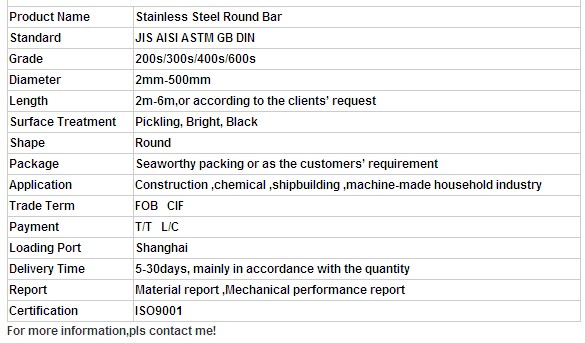

Specifications

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

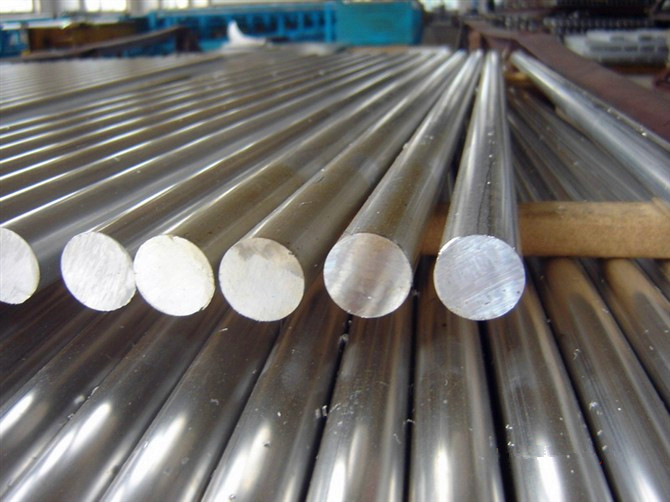

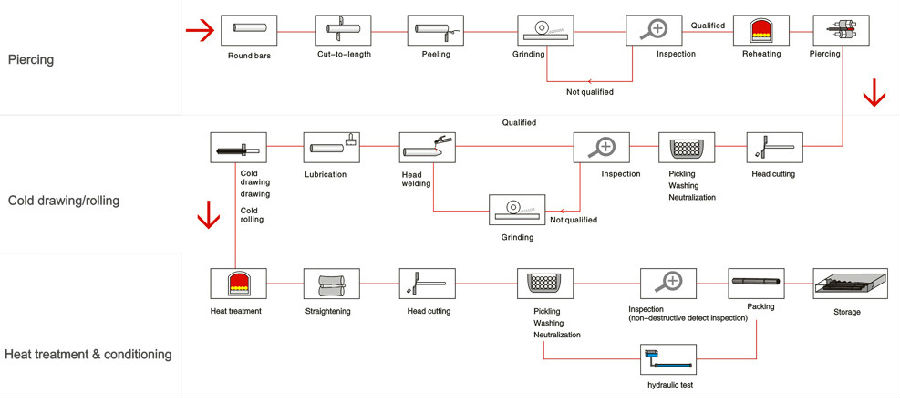

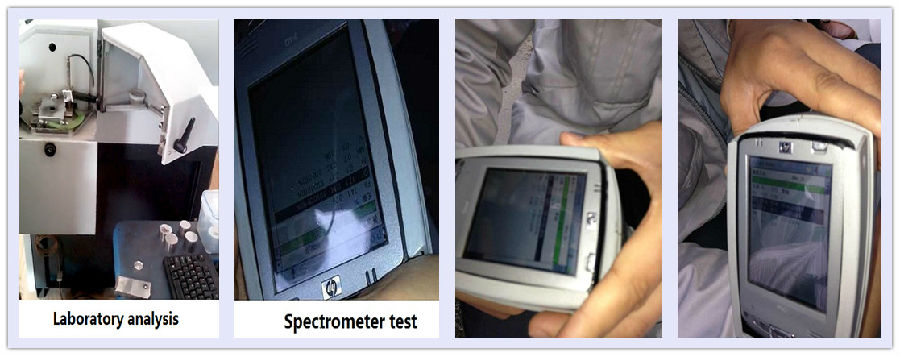

A series of pictures

- Q: Can stainless steel bars be used in cryogenic applications?

- Yes, stainless steel bars can be used in cryogenic applications. Stainless steel is known for its excellent low-temperature properties, which makes it suitable for use in cryogenic environments. The material can maintain its mechanical strength, corrosion resistance, and dimensional stability at extremely low temperatures, making it ideal for applications such as cryogenic storage tanks, liquid natural gas (LNG) equipment, and aerospace components. Additionally, stainless steel offers good thermal conductivity, ensuring efficient heat transfer in cryogenic systems. It is important to choose the appropriate grade of stainless steel that is specifically designed for cryogenic applications to ensure optimal performance and reliability.

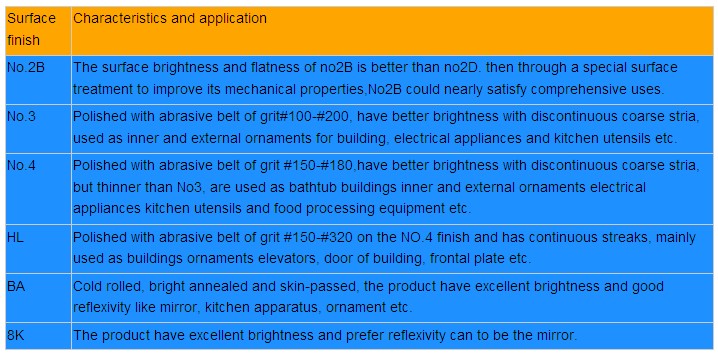

- Q: What are the different finishes available for stainless steel bars?

- There are several different finishes available for stainless steel bars, each offering unique aesthetic and functional properties. Some of the most common finishes include: 1. Mill Finish: This is the standard finish that stainless steel bars have when they come out of the mill. It has a dull, non-reflective appearance and may have slight imperfections on the surface. 2. Brushed Finish: Also known as satin finish, this finish is achieved by brushing the stainless steel surface with a fine abrasive material. It creates a pattern of fine lines or scratches that gives the bar a smooth, matte appearance. 3. Mirror Finish: This is a highly reflective finish that gives stainless steel bars a mirror-like appearance. It is achieved by polishing the surface using progressively finer abrasives until a high level of reflectivity is obtained. 4. Polished Finish: Similar to mirror finish, polished finish involves smoothing the surface of the stainless steel bar to create a shiny, reflective appearance. However, it may not be as reflective as a mirror finish. 5. Bead Blasted Finish: This finish is achieved by propelling tiny glass beads at high pressure onto the stainless steel surface. It creates a uniform, matte texture with a slightly rough feel. 6. Etched Finish: Etching involves selectively removing material from the stainless steel surface using an acid or chemical solution. This creates a pattern or design on the bar, adding a decorative element. 7. PVD Coating: Physical Vapor Deposition (PVD) coating is a process where a thin layer of colored or decorative material is applied to the stainless steel surface. This allows for a wide range of colors and finishes, including matte, glossy, metallic, or textured. These different finishes provide a range of options for stainless steel bars, allowing them to be used in various applications such as architectural, decorative, or industrial uses. The choice of finish depends on the desired appearance, durability, and resistance to corrosion or staining.

- Q: Do stainless steel bars have good resistance to sulfuric acid?

- Yes, stainless steel bars have good resistance to sulfuric acid. Stainless steel is known for its corrosion-resistant properties and it is widely used in various industries due to its excellent resistance to many corrosive environments, including sulfuric acid. The high levels of chromium and nickel present in stainless steel help in forming a passive layer on the surface, which protects the material from the corrosive effects of sulfuric acid. Additionally, stainless steel has good mechanical strength and can withstand the high temperatures associated with sulfuric acid applications. However, it is important to note that the resistance of stainless steel to sulfuric acid depends on factors such as the concentration and temperature of the acid, so it is advisable to consult with experts or refer to the specific grade of stainless steel being used to determine its suitability for a particular sulfuric acid application.

- Q: Can stainless steel bars be used in food packaging applications?

- Yes, stainless steel bars can be used in food packaging applications. Stainless steel is a durable and corrosion-resistant material that is safe for use in contact with food. It offers excellent hygiene, strength, and temperature resistance, making it suitable for various food packaging needs, including storage containers, utensils, and equipment.

- Q: Are stainless steel bars suitable for decorative applications?

- Stainless steel bars are a great choice for decorative purposes. This material is versatile and durable, with a sleek and modern look. It is commonly used in architecture, interior and exterior decoration, furniture, and artwork. You can polish stainless steel bars to a high shine, giving them a reflective and lustrous finish that adds elegance to any space. They can also be brushed or textured to create different visual effects, offering a wide range of design options. One of the main advantages of stainless steel is its resistance to corrosion and staining. This means that the bars will maintain their aesthetic appeal even in tough environments. They are suitable for both indoor and outdoor decorative applications, as they can withstand moisture, sunlight, and harsh weather conditions. Additionally, stainless steel is a strong and long-lasting material. This ensures that the decorative bars will remain structurally intact over time. They are perfect for high-traffic areas or installations where they may come into physical contact. In conclusion, stainless steel bars are a great choice for decorative applications. They offer a combination of aesthetic appeal, durability, and resistance to corrosion. Whether it's for architecture, furniture, or artwork, stainless steel bars can enhance the visual appeal of any space while ensuring long-lasting beauty.

- Q: Are stainless steel bars suitable for agricultural applications?

- Indeed, stainless steel bars prove to be a fitting choice for agricultural purposes. The commendable resistance to corrosion exhibited by stainless steel renders it an optimal option in agricultural settings, where encounters with moisture, chemicals, and other harsh circumstances prevail. Stainless steel bars exhibit durability, enabling them to endure the demanding tasks associated with agricultural operations, such as the handling of heavy loads, with minimal deterioration. Moreover, stainless steel boasts easy maintenance and sanitization, rendering it a hygienic alternative for applications involving food processing or animal husbandry. In essence, stainless steel bars present the necessary attributes of strength, longevity, and versatility required for a diverse array of agricultural uses.

- Q: How do stainless steel bars resist citric acid?

- Stainless steel bars resist citric acid due to their unique composition and characteristics. Stainless steel is primarily composed of iron, along with a minimum of 10.5% chromium. This chromium content creates a protective layer on the surface of the steel, known as a passive film, which makes it highly resistant to corrosion from various chemicals, including citric acid. The passive film acts as a barrier, preventing the citric acid from directly contacting the underlying steel. This film is extremely thin but robust, and if it gets damaged, it can quickly reform in the presence of oxygen. Additionally, the presence of other alloying elements, such as nickel and molybdenum, further enhances the resistance of stainless steel bars to citric acid. Citric acid is a weak organic acid commonly found in fruits and vegetables and is used as a food additive and cleaning agent. While it is relatively mild compared to other acids, it can still corrode or etch certain materials. However, stainless steel's resistance to citric acid is due to its ability to passivate and form a protective layer, which makes it suitable for applications where contact with citric acid is expected. It's important to note that while stainless steel bars are generally resistant to citric acid, the exact resistance can vary depending on the specific grade and surface finish of the stainless steel. In some cases, prolonged exposure to citric acid at high temperatures or in high concentrations may still cause corrosion or damage to stainless steel. Therefore, it is necessary to consider the specific application and consult the appropriate stainless steel guidelines to ensure optimal resistance to citric acid.

- Q: What are the different types of stainless steel bar surface defects?

- There are several types of stainless steel bar surface defects, including scratches, pits, cracks, and stains.

- Q: What is the difference between rough turned and polished stainless steel bars?

- The main difference between rough turned and polished stainless steel bars lies in their surface finish. Rough turned stainless steel bars have a rough and slightly uneven surface, typically achieved through a turning process that removes excess material. On the other hand, polished stainless steel bars undergo additional processing, such as grinding and buffing, to achieve a smooth and glossy finish. This polishing process enhances the aesthetic appeal of the bars and also helps to improve corrosion resistance.

- Q: Are stainless steel bars suitable for the production of wire ropes?

- Indeed, wire ropes can be produced using stainless steel bars, which are renowned for their suitability. Stainless steel, known for its exceptional durability and resistance to corrosion, proves itself to be an optimal choice for situations where wire ropes face harsh conditions or encounter chemicals. The remarkable combination of high tensile strength and outstanding resistance to fatigue makes stainless steel bars a dependable option for the manufacturing of wire ropes. Moreover, stainless steel presents advantageous qualities such as commendable thermal and electrical conductivity, enabling it to serve various industries including marine, construction, and oil and gas.

Send your message to us

cold rolled stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords