1/4 Inch Aluminum Strips - Aluminum 3003/ All Applications Prime Finished Aluminum Coil/ Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

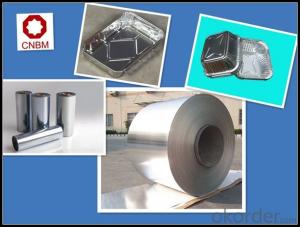

All Applications Prime Finished Aluminum Coil/ Sheet

Main Specification:

Alloy:1235/8011/8079

Temper:H14/H16/H24/H26

Thickness:0.2mm-0.3mm

| Product Name | aluminum coil |

| Alloy No. | 1050, 1060, 3003, 5052, etc |

| Thickness | 0.02-100 mm |

| Width | 40-2550 mm |

| Length | 100-6000 mm |

| Application | Gutter, constructions, decorations, air conditioning and radiators etc. |

| Package | Eye to wall or eye to air |

| MOQ | 3MT |

Applications

Super performance, 40u foil tape. Ideal for sealing joints / seams against moisture and vapor on foil jacketing insulation. Suitable for many other permanent sealing, holding, splicing or masking applications requiring the protection offered by a foil backing.Auminum foil can be divided by shape rolled aluminum foil and sheet of aluminum foil.Aluminum foil deep processing of wool roll most is supply, only a handful of handicraft industry with flake aluminum foil packing occasions.

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP

.

- Q: Is it possible to join aluminum strips together through welding?

- <p>Yes, aluminum strips can be welded. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity and reactivity. Common methods include gas tungsten arc welding (GTAW), also known as TIG welding, and gas metal arc welding (GMAW), or MIG welding. These processes involve using a filler material and an inert shielding gas to prevent oxidation. Proper preparation, such as cleaning the aluminum surface and controlling the heat input, is crucial for a successful weld.</p>

- Q: Is it possible to incorporate recycled materials into construction, specifically using aluminum strips for roofing?

- <p>Yes, you can use recycled materials in building construction. Aluminum strips are often made from recycled aluminum, which is a sustainable choice. Recycled aluminum requires significantly less energy to produce compared to new aluminum, reducing environmental impact. It's important to ensure that the recycled materials meet quality standards for construction and are sourced responsibly. Using recycled aluminum for roofing can contribute to a greener building project and help in waste reduction.</p>

- Q: What types of aluminum strips are more appropriate for industrial purposes?

- <p>Yes, there are specific types of aluminum strips that are more suitable for industrial applications. These include 1100 series aluminum strips, known for their high purity and excellent corrosion resistance. 3003 series strips are also popular for their good formability and weldability, making them ideal for applications like chemical equipment and aircraft parts. Additionally, 5052 series strips are valued for their strength and resistance to marine environments, often used in shipbuilding and offshore structures. Each type is chosen based on the specific needs of the industrial application, such as strength, malleability, and environmental resistance.</p>

- Q: What distinguishes extruded aluminum strips from rolled ones in terms of manufacturing process and properties?

- <p>Extruded aluminum strips are formed by forcing aluminum through a die, creating a specific profile or shape. This process results in a more uniform cross-section and can produce complex profiles. Extruded strips are stronger and have better dimensional stability due to the grain flow being aligned with the direction of the extrusion. Rolled aluminum strips, on the other hand, are created by passing aluminum between rollers to achieve the desired thickness and width. This method is more suitable for producing thin, wide strips and is less costly for simpler profiles. Rolled strips may have some residual stresses and are not as strong as extruded ones, but they are more flexible and can be used in applications requiring formability.</p>

- Q: What are the environmentally friendly options for aluminum strips?

- <p>Yes, there are environmentally friendly types of aluminum strips. Recycled aluminum strips are more eco-friendly as they require significantly less energy to produce compared to virgin aluminum. Additionally, using aluminum strips with a high recycled content reduces waste and conserves natural resources. Another option is to look for aluminum strips that are produced using renewable energy sources, which further reduces their carbon footprint. Lastly, choosing aluminum strips with a lower coating or treatment that is biodegradable or has a lower environmental impact can also contribute to their environmental friendliness.</p>

- Q: What are the potential health risks related to the use of aluminum foil?

- <p>While aluminum foil is widely used in cooking and food storage, there is limited evidence to suggest significant health risks. Some studies have linked aluminum exposure to neurological conditions like Alzheimer's, but the connection is not conclusive. The body does not absorb significant amounts of aluminum from foil, especially when used properly. However, it's important to avoid wrapping acidic or highly acidic foods in aluminum foil, as this could potentially lead to increased aluminum leaching. Overall, using aluminum foil in moderation and following proper food handling practices can minimize any potential risks.</p>

- Q: Describe how the weight of an aluminum strip compares to other common roofing materials.

- <p>An aluminum strip is significantly lighter than many other roofing materials. It weighs approximately 1.5 to 2.5 pounds per square foot, depending on the thickness and profile. In contrast, asphalt shingles can weigh between 2.5 to 4.5 pounds per square foot, while concrete tiles can be as heavy as 7 to 10 pounds per square foot. Clay tiles are also heavier, typically ranging from 6 to 8 pounds per square foot. This makes aluminum strips an attractive option for those seeking a lightweight roofing solution.</p>

- Q: The user is inquiring if it's possible to utilize recycled aluminum for their roofing project.

- <p>Yes, you can use recycled aluminum for your roofing project. Recycled aluminum is not only environmentally friendly but also cost-effective. It retains the same strength and durability as new aluminum, making it an excellent choice for roofing. It's lightweight, resistant to corrosion, and can be easily shaped and installed. Additionally, using recycled aluminum helps reduce waste and conserves natural resources. However, it's important to ensure that the recycled material meets quality standards and is sourced from a reputable supplier to guarantee its performance and longevity.</p>

- Q: What are the various color options for aluminum strips?

- <p>Aluminum strips are available in a variety of colors to suit different applications and aesthetic preferences. Common colors include natural silver, which is the standard mill finish, black, white, and clear anodized for a protective and decorative finish. Other colors like gold, bronze, and various shades of blue, green, and red are also offered by some manufacturers. Custom colors can be achieved through anodizing or powder coating processes, allowing for a wide range of color options to meet specific design requirements.</p>

- Q: This question asks for methods to identify if the roof material is aluminum strips.

- <p>To determine if your roof is made of aluminum strips, you can look for the following characteristics: 1) The roof has a shiny, metallic appearance, which is typical of aluminum. 2) The strips are lightweight and flexible, making them easy to handle. 3) They are often interlocking, which is a common feature of aluminum strip roofing. 4) Check for any manufacturer's markings or labels that might indicate the material. If you're unsure, a professional roof inspector can help confirm the material by examining the roof closely or taking a small sample for testing.</p>

Send your message to us

1/4 Inch Aluminum Strips - Aluminum 3003/ All Applications Prime Finished Aluminum Coil/ Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords