030 Aluminum Coil - Aluminium Coated Coils for Cladding System and Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

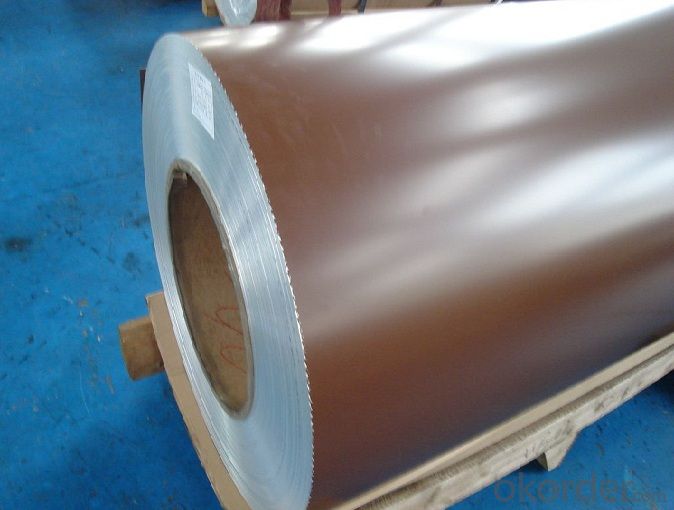

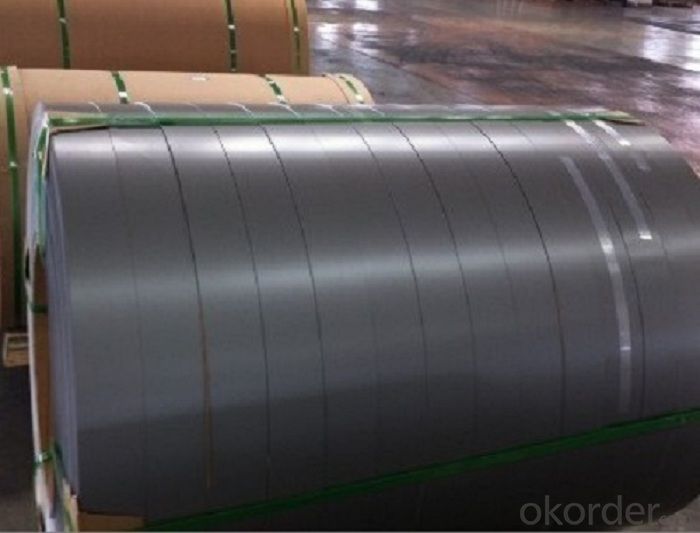

Aluminium Coated Coils for Cladding System and Roofing

l Product Information

| Alloy | 1050 1060 1100 3003 3004 3005 5005 8011 etc |

| Temper | H12, H14, H16, H18, H24, H26 |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1240mm |

| Special width: 1300mm,1520mm,1570mm,1595mm | |

| Diameter | Standard dia:1200mm |

| Interior dia:150mm,405mm,505mm | |

| Weight | 2.5 T/coils, 3.0 T/coil |

| Coating | PE, PVDF,ACRYLIC |

| Surface | Embossed, mill finish, coated |

| Color | As to code RAL |

| Gloss | 10-90% (EN ISO-2813:1994) |

| Coating Thickness | PE:more than 18 micron |

| PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

| Coating Adhesion | 5J(en iso-2409:1994) |

| Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility (T-bend) | 2T |

| MEK resistance | more than 100 |

| Advantage | 1.High temperature resistant 2.Weathering resistance 3.Scrubbing resistant 4.Sound insulation 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

| Out package | wooden splint with export standard |

| Application | ACP,wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels , etc |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Can aluminum coils be used in chemical processing plants?

- Yes, aluminum coils can be used in chemical processing plants. Aluminum is resistant to many chemicals, especially in non-acidic environments. It is lightweight, has good thermal conductivity, and can withstand high temperatures, making it suitable for various applications in chemical processing plants.

- Q: Four roller rolling mill roller bearing on the aluminum top how always have holes, in the production process, will be printed on just above the work roll, the work roll used in less than a day, it will produce a pothole, and aluminum plate will be printed from the upper supporting roller above the straight line, the line in the above there are holes.

- Well, typical aluminum plate surface defects in the backup roll print, solution, change support roll.Do not know your factory function division, should have special polishing work roll, support roller grinding workshop, this problem should be addressed to them, sticks are not qualified, how can dry out qualified products?

- Q: Can aluminum coils be used in automotive heat exchangers?

- Yes, aluminum coils can be used in automotive heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent heat transfer properties, lightweight nature, and corrosion resistance. It is widely used in automotive radiators and air conditioning systems to efficiently transfer heat and cool the engine or cabin.

- Q: How are aluminum coils stored to prevent damage?

- Aluminum coils are typically stored in a clean, dry, and well-ventilated area to prevent damage. They are often stacked horizontally or vertically on pallets or racks to ensure stability and avoid bending or deformation. Additionally, protective coverings or packaging materials such as plastic wraps or cardboard boxes may be used to shield the coils from moisture, dust, and other potential sources of damage.

- Q: Are there any limitations to the widths of aluminum coils?

- The widths of aluminum coils are subject to certain limitations. Various factors, such as the manufacturing process, equipment capabilities, and industry standards, determine the width of these coils. One limitation arises from the maximum width that the manufacturing equipment can handle. Coil processing machines have specific width capacities, typically ranging from a few inches to several feet. If an aluminum coil exceeds the machine's maximum width capacity, it may not be feasible to process. Another limitation relates to transportation and handling. Aluminum coils that are too wide may not fit into standard shipping containers or may be challenging to maneuver during transportation. Moreover, wide coils may necessitate specialized handling equipment or additional support, leading to increased costs and logistical difficulties. Industry standards and application requirements also influence the limitations on aluminum coil widths. Different industries and applications have specific width specifications for their products. For instance, the construction industry may have particular width requirements for roofing or cladding materials, while the automotive industry may have different demands for body panels. Manufacturers must take these standards and customer needs into account when determining the maximum and minimum widths of aluminum coils. To summarize, while aluminum coils can be produced in various widths, there are limitations due to manufacturing equipment capabilities, transportation constraints, and industry standards. These limitations must be considered to ensure the efficient production, handling, and utilization of aluminum coils in different applications.

- Q: This question asks for the most effective methods to clean an aluminum coil, which is a common component in various industries.

- <p>The best ways to clean aluminum coils involve a combination of mechanical and chemical processes. Mechanical cleaning can be done using brushes or pressure washing to remove loose dirt and debris. Chemical cleaning involves using a suitable aluminum cleaner or mild detergent solution to dissolve stubborn grime. Always rinse thoroughly with water to remove any residue. Avoid abrasive materials or harsh chemicals that could scratch the surface. Regular cleaning and maintenance can prevent buildup and extend the coil's lifespan.</p>

- Q: How do aluminum coils withstand extreme weather conditions?

- Aluminum coils are able to withstand extreme weather conditions due to the unique properties of aluminum. Firstly, aluminum is a lightweight material, which allows it to be flexible and resistant to bending or warping under high winds or heavy snow loads. This makes aluminum coils less likely to sustain damage during extreme weather events such as hurricanes or blizzards. Additionally, aluminum has a high resistance to corrosion. It forms a protective oxide layer on its surface when exposed to air, which prevents the metal from rusting or deteriorating when exposed to moisture or harsh weather conditions. This protective layer acts as a barrier against elements like rain, snow, or saltwater, making aluminum coils highly durable and long-lasting. Furthermore, aluminum has a high thermal conductivity, which means it can quickly dissipate heat. This property allows aluminum coils to efficiently transfer heat away from the system, preventing overheating and potential damage during hot weather conditions. The ability to dissipate heat effectively also contributes to the energy efficiency of aluminum coils. Finally, aluminum is a non-magnetic material, which means it is not affected by electromagnetic interference or lightning strikes. This makes aluminum coils safe and reliable in areas prone to electrical storms or high electromagnetic activity. In conclusion, aluminum coils are designed to withstand extreme weather conditions due to their lightweight, corrosion-resistant, thermally conductive, and non-magnetic properties. These characteristics make aluminum coils highly durable, reliable, and suitable for use in a wide range of applications, including HVAC systems, automotive cooling, and electrical wiring.

- Q: I'm 14 an was told that aluminum free deodorant would stop yellow stains on my white shirts, so which female deodorant would help stop yellow stains

- Deodorant with aluminum also causes breast cancer. I use Toms of Maine deodorant, which is aluminum-free.

- Q: Can kerosene lubricate and cool aluminum coil when continuous punch?

- Yes, because water and oil are not solute, but they will emulsificate.

- Q: Hi i need to know what will happen to the impact strength of aluminum 2024 reinforced with Silicon carbide is treated to cryogenic temperature (nearly -200C). Will impact strength increase or decrease. Also will the impact strength vary with respect to the percentage of Silicon carbide.

- Aluminum 2024 doesn't have a transition temperature, it absorbs about 18n-m impact strength (via charpy tests I ran three weeks ago at my College course). This was constant between -150?C to +150°C (liquid nitrogen to a furnace). This excerpt from wiki: Cutting tools In 1982 at the Oak Ridge National Laboratories, George Wei, Terry Tiegs, and Paul Becher discovered a composite of aluminium oxide and silicon carbide whiskers. This material proved to be exceptionally strong. Development of this laboratory-produced composite to a commercial product took only three years. In 1985, the first commercial cutting tools made from this alumina and silicon carbide whisker-reinforced composite were introduced by the Advanced Composite Materials Corporation (ACMC) and Greenleaf Corporation. Leads me to believe it depends on how you mix the material in would make a difference. Silicon Carbide and aluminum make very strong tools, but would make it more brittle. The ceramic in a metallic crystal lattice (metal is a crystalline structure) would allow more voids to coalesce leading to a brittle fracture, but the initial strength would be improved because of substitution dislocations in the crystal structure (it would be more rigid, stronger, but more prone to sudden failure). Silicon carbide has low thermal expansion coefficient compared to aluminum also so when it gets really cold the aluminum would contract around the particles increasing the strength, but again, reducing ductility and causing fractures to occur more rapidly. Anyways, very interesting, you should do a bit of research on your own after this as I gave you some good places to work from (and I'm sure plenty of words to look up ;D )

Send your message to us

030 Aluminum Coil - Aluminium Coated Coils for Cladding System and Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords