0.4KW~3.7KW Single Phase AC Motor Drive

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc pc

- Supply Capability:

- 8000pcs per month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of 0.4KW~3.7KW Single Phase AC Motor Drive

0.4KW~3.7KW Single Phase AC Motor Drive is a high-quality, multi-function, low-noise variable frequency drive which is designed, developed and manufactured according to international standards. It can meet different needs of industrial conditions.The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse

Features Of 0.4KW~3.7KW Single Phase AC Motor Drive

1).Adopts 16 bit microprocessor, sine wave PWM control2).Automatic torque ascension and automatic sliding compensation function

3).Output frequency 0.1-400 Hz

4).8 period of speed setting and 7 period can be running the program

5).Low noise, carrier frequency can from 1 kHz-15 kHz adjustment

6).Two paragraphs Acceleration and deceleration time and two segments of the S Curve slow and deceleration

7).Simulation frequency set acceptable 0-10 VDC, 4-20 mA

8).The built-in serial communication interface RS-485(baud rate can reach 38400)

9).Save energy running and automatic voltage stabilizing section function (AVR)

10).Adjustable V/F curve Acceleration and automatic and deceleration function

11).Simple vector control and built-in PID control, and the simple positioning function

12).Sleep/wake up function and zero velocity keep function

Structure Of 0.4KW~3.7KW Single Phase AC Motor Drive

Application Of 0.4KW~3.7KW Single Phase AC Motor Drive

★Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.★Plastic: extruder, hauling machine, decorating machine, etc.

★Pharmacy: mixer, roaster, etc.

★Woodworking: engraving machine, sander, veneer peeling lathe, etc.

★Papermaking: single type papermaking machine, etc.

★Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

★Printing: cloth-washing machine, dye vat, etc.

★Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

★Fan and pump: kinds of fans, blowers and pumps

Performance Of 0.4KW~3.7KW Single Phase AC Motor Drive

| Item | Specification | |||||||

| Input | Rated voltage | T4 series: Three phase 380v, ±15% | ||||||

| Frequency | S/T2 series: Three/single phase 220V, ±15% | |||||||

| 50/60Hz ±5% | ||||||||

| Output | Voltage | T4 series: Three phase 0-380V | ||||||

| Frequency | S/T2 series: Three phase 0~220v | |||||||

| 0-400Hz | ||||||||

| Overload ability | 150% rated current for 30s; 180% rated current for 1s; | |||||||

| Dissipation | Cooling type | Forced Cooling | ||||||

| Temperature protection | Heatsink temperature >85℃ trip protection against overheat | |||||||

| Fan control | Heatsink temperature> 50℃, fan forced operation, frequency inverter continue work | |||||||

| Control | Control mode | Open-loop vector control, V/F control | ||||||

| Performance | Start torque | Open-loop vector control: 0.5Hz 180%; | ||||||

| VF control: 0.5Hz 150% | ||||||||

| Speed range | Open-loop vector control:1:150; | |||||||

| VF control:1:100 | ||||||||

| Speed control precision | Open-loop vector control: ±0.2%; | |||||||

| VF control:±0.5% | ||||||||

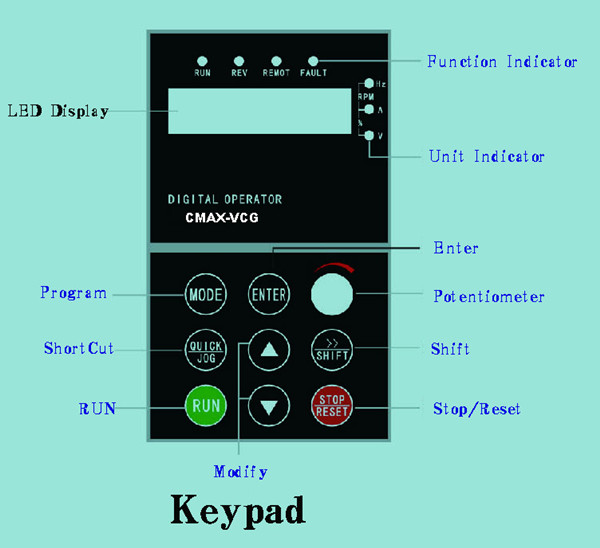

| Function | Channel of operation command | Keyboard control,terminal control,communication control | ||||||

| Start mode | Direct start, DC injection braking before start, speed tracking before start | |||||||

| DC injection braking | Start DC injection braking, stop DC injection braking | |||||||

| Dynamic braking | Built-in braking unit | |||||||

| Frequency source choice | Keyboard digital frequency setting, analog AVI setting | |||||||

| PID control setting, telecommunications setting | ||||||||

| Frequency resolution | Keypad setting:0.01Hz; Analog setting: 0.1% | |||||||

| Carrier frequency | 1Khz~12Khz, | |||||||

| Acc/Dec time | 0.1~6000.0s or 0.01~600.00s | |||||||

| Signal | Analog input | AVI:0~10V | ||||||

| ACI:4~20mA | ||||||||

| Keyboard potentiometer input: 0~10V | ||||||||

| Analog output | AFM:0~10V or 0~20mA, Select through JP1 jumper | |||||||

| Digital input | A total of 28 kinds of function could be selected from S0 ~S5. | |||||||

| Digital output | 1 channel open collector output(MO1-MCM) | |||||||

| 1 channel relay output( TA-TC normally open, TB-TC normally closed; | ||||||||

| Communication Port | Communication protocol | Based on RS485 hardware, support standard MODBUS protocol. | ||||||

| Display Functions | Four digital tube display | Can monitor the operation state of frequency inverter flexibly and conveniently. | ||||||

| Installation | Humidity | Less than 90%RH | ||||||

| condensation | ||||||||

| Vibration | Less than0.6G | |||||||

| Elevation | 0~1000m, reduce the rated specification 10% when lift 1000m for each. | |||||||

| Storage temperature | -20~60℃ | |||||||

| Structure | Defend degree | IP20 | ||||||

- Q: Can the laptop's power adapter be used for years?

- In the power adapter has a nameplate, marked above the power, input and output voltage and current and other indicators, with particular attention to the input voltage range, which is the so-called "travel power adapter", if the city voltage to only 110V country , This feature is very useful, and some parallel notebook computers are sold only in the origin, there is no such compatible voltage design, or even only a single 110V input voltage, in our 220V mains voltage will be burned to burn.

- Q: Notebook power adapter on how to look at power

- It should be noted that there are many in Japan to buy a notebook or over there in the parallel imports, input only support 110V in China is not used, because the Chinese standard is 220V. Now the subject is 90W 20V. Output voltage and power will be identified, such as the target for the 90W 20V, that output power is 90W, the output voltage is 20V. If only the output voltage and output current are identified,

- Q: What is the difference between variable frequency motor and variable speed motor?

- Give you a formula, you can understand their speed control principle: N (speed) = 60f (frequency) divided by P (magnetic pole logarithm) According to the formula, when you want to change the motor speed, there are only two ways to change The number of pole pairs and the frequency of the power supply. Speed ??motor is variable pole speed, that is, in this motor has 2 to 3 sets of windings, by changing the winding connection, to change the motor pole to change the rotation speed.

- Q: Laptop adapter heat

- Therefore, in the design and production of switching power supply, we must choose high temperature components. Of course, be sure to control the temperature of the power supply within the allowable range of the application environment. First, the conversion efficiency should be designed as high as possible, and secondly, to use the pressure drop is small, low loss of switching components, the third is to be thermal design, cooling area to be as large as possible, more than 100W switching power supply Should have a metal perforated shell, or add a cooling fan. The current notebook power adapter power is generally around sixty or seventy W, the use of high temperature plastic fire sealed package, the internal heat generated by the plastic shell mainly distributed out. Therefore, the power adapter surface temperature is still quite high, the maximum temperature or even reach about 70 degrees! Think of the inside of the adapter, it is not like the fire! So, when you use the laptop, try to place the power adapter in a better place to ventilate heat, do not put books and the like on the power above. As for the kind of hot feeling, do not have to worry about is the power, not angry strange!

- Q: Yaskawa inverter reported base blockade what is the reason?

- This is the base block command, when the external input block command signal, the inverter will appear this code, the code appears, the motor will be free to rotate, does not affect the use.

- Q: Master Hello a machine requires 500 speed matching 6-pole motor frequency converter transferred to about 28HZ

- 6-pole motor synchronous speed of 1000 r / min, the actual motor speed is lower than the number, the actual speed is required to 500 r / min, then the motor and passive pulley diameter ratio of about 1: 1.6 or so, and then specific With the inverter to speed up to achieve the purpose, please refer to.

- Q: Why the number of motor poles increased, the inverter capacity will increase

- The power of the three-phase motor is equal to the root number of 3 times the line current and the line voltage of the product again good with the power factor. Can also be 3 times the phase current and phase voltage of the good product and then good to power factor. The frequency converter should match the rated current of the motor, not the power of the motor.

- Q: What are the AC motor speed control methods? What are the characteristics of each

- Pressure control speed, limited speed range is limited use of variable pole speed, change the motor internal wiring speed, speed is a very speed according to the motor factory set to brand speed to speed control, change the motor input Frequency to speed, are stepless speed is now more popular

- Q: Short-term short-circuit converter DC link positive and negative will damage the inverter?

- the switch signal Is the fan running up after the speed line is low, this can be shorted. Pulse is every turn a circle, send two pulses to the speed line

- Q: 30 kW 6 pole frequency motor torque is how much

- Look at the motor sample or nameplate, above some Different manufacturers of the motor may be different I have a sample on hand, 90KW, six pole, frame number 315M1, rated current 168A, rated torque 859.4 And then look at your inverter performance and motor performance, and can generally be overloaded to the rated torque of 150%

1. Manufacturer Overview

| Location | Liaoning,China |

| Year Established | 2001 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | DALIAN |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | ENGLISH,CHINESE |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

0.4KW~3.7KW Single Phase AC Motor Drive

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc pc

- Supply Capability:

- 8000pcs per month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords