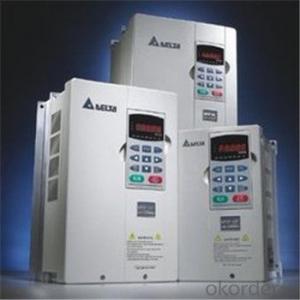

Variable Frequency Inverter/VFD for fan and Water Pump

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

From the above, different voltage output, the quantity of power units is different, but the working theory is exactly identical. All power units receive the indicator from same central process controller. There is a phase difference in secondary windings of transformer which provide energy for power unit, in this way, most of the harmonics current caused by independent power unit will be eliminated, so the primary winding current is approximately sine wave, the harmonics current flowing into power grid are so few, even under the rated load, the harmonics contents is lower of 3%.

The power unit is AC-DC-AC structure, equivalent to a low-voltage power source inverter of 3-phase input single-phase output. The rectifier side is diode three-phase full bridge circuit and the IGBT inverter bridge can be controlled through sine PWM mode to output single-phase AC. All power units are fully identical in structure and electrical performance, very easy for maintenance and replacement.

Energy Saving Fields

Power Generation: Induced draft fan, forced draft fan, condensate pump, feed pump, primary air fan, secondary air fan, booster fan, circulating pump, mill fan, slurry pump etc

Cement: draft fan, high-temperature fan, air blower, dust collection fan, grinding machine etc.

Metallurgy: blast furnace blower, slurry pump, feed water pump, dust fan, compressor etc.

Petroleum&Chemical: Water injection pump, crude oil pump, Compressor, fan, circulation pump, etc

Urban water supply: Water delivery pump, water intake pump, water supply pump, sewage treatment industry, self-fractionating pump etc

Minerals & Mining: Mud pump, ventilation fan, belt conveyor, slurry pump etc

Others: Loads such as fan, pump and compressor in pharmaceutical, paper making and wind tunnel test.

Patented automatic recovery technology

With real-time monitoring, the VFD system can identify the causes of power cell bypass, and automatically restarts once it detects the problems are fixed. It ensures equipment to operate continuously and stably when the bus power supply has instantaneous failure.

Our VFD’s ventilation system is centralized and vertical. It has significant advantage over the distribution type in terms of temperature field control, air flow distribution, and wind speed uniformity. Since the capacitor units are located at the ventilation ducts, it is estimated that the lifetime of capacitor can be doubled, and thus the overall system service time is prolonged with this cooling mechanism.

- Q: Laptop power adapter repair how much money

- Different notebook power adapter models are different, the price gap is large. ? Maintenance costs to see the specific model and damage level position. Generally do not recommend maintenance, it is recommended to replace the more appropriate. If you are not covered by the warranty period, you can repair free of charge. Hands-on ability to recommend self-repair, pay maintenance department recommended. After all, once again a greater chance of damage.

- Q: The relationship between the power supply of the notebook and the battery

- 1, when the notebook battery is fully charged, and connected to the power adapter, usually by the adapter directly to the host power supply, this time the battery is idle, the adapter power supply without battery conversion.

- Q: Is the speed of the motor controlled?

- Change the external conditions, you can change the motor speed: 1. Change the number of pole pairs of the motor. (Multi-pole motor use) 2. Use the frequency converter to change the frequency speed 3. Winding motor rotor series resistance speed control. 4. Slip motor is to change the slip electromagnetic speed

- Q: Will the motor suddenly stop when the inverter is suddenly powered down?

- Generally in the absence of external brake or brake case, if the power, the motor is in a free stop state, uncontrolled,will gradually slow down to 0

- Q: Laptop power adapter (no power supply, but indicator light)

- There may be reasons for the power adapter, there may be a computer can not identify the power supply is battery-powered or AC power. These are just speculated by your phenomenon, if you are better in the warranty period to the customer service test, so the best

- Q: Laptop power adapter output voltage is not the same as the current? What's the effect?

- In the case of other conditions (rated output voltage, plug polarity, etc.) the same circumstances, the rated output current greater power adapter, can replace the rated output current is relatively small power adapter, which is not adversely affected. If the power adapter with a relatively small rated current is used instead of a relatively large power adapter with a rated output current, the power adapter will be "overloaded" and may cause damage to the power adapter.

- Q: Do not the laptop directly connected to the power adapter?

- 2, due to the different configuration of the notebook, its power consumption also has a variety of specifications. Common for more than 60W, the configuration of some of the 90W, and the game adapter power in more than 120W, such as dual GTX1080 card crossfire Blue Star prototype, power consumption in more than 400W, the use of two 320W power adapter for its power supply;

- Q: On the laptop power adapter problem

- Notebook power adapter matching the principle of the principle is: the input voltage to meet the requirements of the domestic exchange is 220V; output voltage and the original with the same output current must be greater than or equal to the original adapter output current, your future output current is less than the original will appear Power from time to time unexpected shutdown caused by increased data loss, the battery charge is not easy to rush to cause the battery aging process, the other adapter long-term work will increase the heat caused by increased safety risks.

- Q: Lenovo g450 laptop power adapter specifications is what?

- Input: 100-240V ~ 1.5A 50-60Hz Output: 19V - 4.74A

- Q: 30 kW 6 pole frequency motor torque is how much

- 30 kW 6 pole frequency motor torque is how much 860. 1, the motor torque calculation Motor "torque", the unit is N? M (beef) 2, the formula is T = 9549 * P / n. 3, P is the motor rated (output) power unit is kilowatts (KW) The denominator is the rated speed n units are per minute (r / min) P and n can be found directly from the motor nameplate.

Send your message to us

Variable Frequency Inverter/VFD for fan and Water Pump

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords