FRP Composite Pipes - Fiberglass Reinforced Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Grille Description

1) Corrosion resistence, long service life

2) Light Weight,high strength

3) Non-electrical conduction

4) Maintenance free

2. Main Features of FRP Grille

1) Safety:FRP is recommended when corrosion protection and safety are your goal.

2) Stability:Expansion and contraction is 24% and 50% less than aluminum and steel,providing greater dimensional stability.

3) Durability:Superior durability to Stainless Steel, Aluminum, and Galvanized Gratings, especially in highly corrosive environments.

4) Strength:50%higher tensile strength than hot rolled steel and better impact resistance.

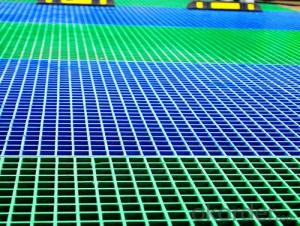

3. FRP Grille Images

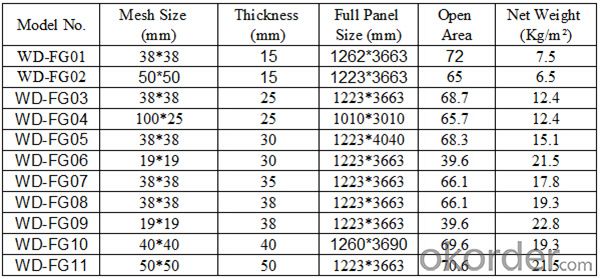

4. FRP Grille Specification

5. FAQ of FRP Grille

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What is the stiffness of FRP pipe?

- The ring stiffness is the comprehensive parameter of the tube's resistance to external pressure. Obviously, the choice of ring stiffness is one of the keys to ensure the safe operation of plastic underground drainage pipe under the external compressive load. If the ring stiffness of the tube is too small, the tube may undergo excessive deformation or buckling failure. On the other hand, if the ring stiffness is chosen too high, the excessive cross section moment of inertia must be used, which will result in too much material and too high cost.

- Q: What can be done to solve the leakage of FRP pipe?

- DN1800 FRP pipe pressure of 9 kilograms, the pressure is very high, crushed by stones, not repaired will certainly leak, the pressure pipe leakage is very bad, will be washed away the soil, spewing a few meters high water column.

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- The service will be restored in 24 hours, and I hope this will help you! Can private letter to contact is not clear!

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- Very simple, ah, first install the septic tank, and then drain the pipe ah!

- Q: Would like to ask about the plastic lined steel pipe, steel pipe, glass steel skeleton, the advantages and disadvantages of each ceramic pipe, to know a friend told, very grateful!

- Plastic lined steel pipe of strong corrosion resistance, heavy quality, need to be made, on-site installation, if the size deviation cannot be installed. The price is more than 5 times more expensive than that of FRP

- Q: What is the structure and function of glass fiber reinforced plastic lining?

- The structure is made up of colloid + glass cloth. The construction process is like this:1, carbon steel inner wall grinding acute angle, rust removal2, brushing glue3, cloth affixed4, brushing glue5, cloth affixed

- Q: Who knows, how is the glass reinforced septic tank connected with the municipal pipe?

- Septic tank (Hu, F, NCH) is the treatment of nightsoil and to filter precipitation equipment. The principle is that the cured material decomposes at the bottom of the tank, and the upper hydration object flows into the pipeline to prevent the pipe from clogging and has enough time to hydrolyze the solidified object (such as excrement and urine). Tank (septic) refers to the division of living sewage sludge, and anaerobic digestion of sludge structure of small structures.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Epoxy coal tar pitch is a kind of anti-corrosion form with high cost performance. The engineering test shows that the epoxy coal asphalt is used as cathodic protection.

- Q: How can FRP tanks be connected to steel tubes?

- Field bonding process is usually provided by glass fiber reinforced plastic manufacturers, if there is no way, I can provide some experience for reference, there is little information, experience only.

- Q: A basic overview of FRP pipes

- FRP pipes are used in petroleum, chemical and drainage industries. Glass fiber reinforced plastic pipeline production in China has developed rapidly, and the quantity has been increasing year by year, and the scope of application and departments are becoming wider and wider.

Send your message to us

FRP Composite Pipes - Fiberglass Reinforced Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords