Composite Pipe (FRP/GRP/GRE) Reinforced Concrete Pipe

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

API Hot Spring Pipe

1.Standard:API,ASTM,ISO,GB, etc

2.Anti-corrosion & high strength

3.Long service time

4.Low costs

GRE (Glass Reinforced Epoxy)

Some times, GRE and FRP/GRP (Fiber/Glass Reinforced Plastic) are regarded as the same

material with different names, but in most cases, since GRE choice epoxy resin as material,

it has stronger performances.

It is the thermosetting plastic products combining the reinforced material of fiberglass roving with the base material of epoxy resin.

It is made by mechanical filament wound process controlled by computer.

So it is a kind of composite material.

The GRE pipe offers a unique combination of chemical resistance, size stability, high strength, and thermal/electric non-conductivity.

So the GRE pipe can be used in the fields of chemical anti-corrosion, construction, electric insulation, power development etc.

Features:

1. Anti corrosion

2. High strength, more safety

3. More than 30 years service life

4. Light weight, easy installation and keeping cost

5. Flexible design and shorter reform term

6. No medium pollution

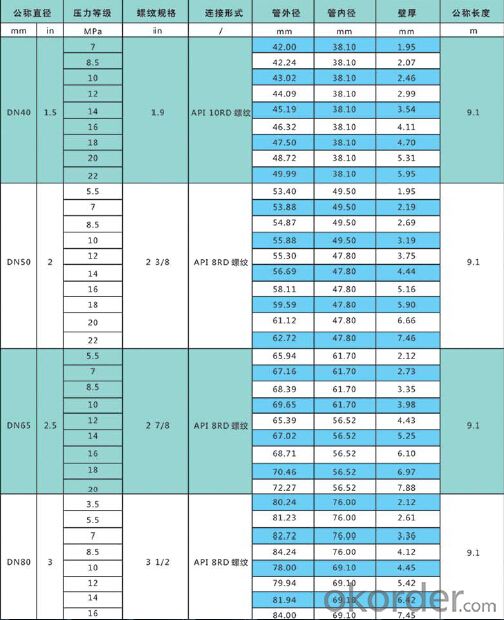

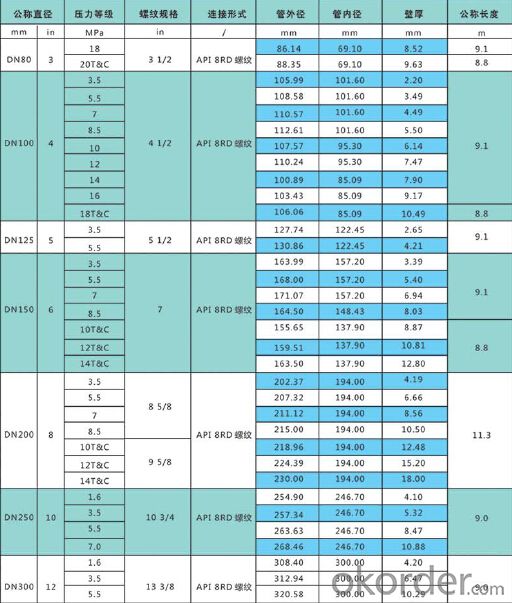

Technical Table

Applications:

1.Oil, petroleum, natural gas pipeline

2.Irrigation, hot spring, city water pipeline

3.Brine delivery pipeline

4.Other liquid transport pipeline

Strength:

1.High quality

We're state owned manufacturer with registered capital RMB 200 million specialized in this area.Standard:API-15HR,API-15LR,ISO9001,GB,etc.

2.Competitive price

Our raw material is from PPG SINOMA JINJING FIBERGLASS CO.,LTD, a JV enterprise

invested by our company and PPG industries to ensure high quality and low costs.

3.Great production capacity and short delivery time.We have 16 production lines for GRE pipe, with annual production capacity of 16000MT.

Pitcures of our factory:

FAQ of GRE pipes:

Q1: What’s the performance standards?

Lianzhong pipe is designed to meet all of these ASTM , AWWA, BS, DIN standards.

Q2: What’s the qualification testing for the products?

Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and DIN 16868 requirements

Q3: How long can I receive my goods?

A: Usually, we will deliver products within 20 days after the contract is signed. Delivery time is negotiable when necessary.

- Q: Designed to support FRP pipes, is it m or mm?

- The glass steel pipe wall smooth, do not scratch the cable, socket type interface, convenient installation and connection to thermal expansion and contraction, the proportion of small, light weight and reduce installation labor, reduce the cost of installation, FRP cable protection pipe used for electric power, communication cable, in various environmental protection pipe laying cables, especially through the traffic crossing to the cable across the river the use of the bridge, under special circumstances, can fully reflect its simple construction, high strength, excellent performance, widely used in electric power, communications, transportation, civil aviation, airport infrastructure and other Domain company always adhere to the "customer first, integrity management, intentions services for business philosophy, is willing to work with friends from all walks of life to strengthen cooperation, mutual cooperation, common progress and win-win

- Q: Why FRP pipes for outdoor waste gas treatment equipment are selected?

- Glass fiber reinforced plastic properties: light and hard, non conductive, stable performance, high mechanical strength, less recycling, corrosion resistance.

- Q: Why FRP pipe corrosion?

- No material was selected. If there is corrosive requirements, it is necessary to use corrosion-resistant materials to make glass fiber reinforced plastic pipe.

- Q: Is it useful to make gas pipelines with glass steel pipes? Or the idea that the technology is mature?

- I don't think it's enough, because the strength of FRP is not enough, it can easily be brittle and easily perforated in the field for a long time!

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- The basic thing is to finish the heat preservation. Soak the PP cloth soaked in the solution and finish it. Then brush it one or two times. The key is to make the solution, with water heating method, or else not. If you want to strengthen the strength, you can finish the insulation, and then wrapped a layer of 10---20 purpose wire mesh, and then made glass fiber reinforced plastic

- Q: What are FRP pipes?

- The glass steel base material and reinforcing material composition, because of different base material we have called GRE, some called GRP, the matrix material is generally resin reinforced material is glass fiber, adding other raw materials in the production process to obtain more excellent performance, such as adding graphite or carbon fiber can be obtained antistatic, using phenolic resin as matrix material, can obtain very high temperature resistant ability, can withstand instantaneous temperature of 3000 degrees celsius. The glass steel pipe in recent years in the shipbuilding industry is very popular and special attention, such as ship oil tankers, chemical tankers, offshore platform and ship ballast system, at the request of foreign shipowners in the use of glass steel pipes and fittings, its advantages in addition to the static electricity can guide, there are many advantages. Such as light weight, FRP pipe the same general size is only 35% of the weight of the steel pipe, is resistance to seawater corrosion, general steel and glass pipe manufacturers can promise: 50 years. Its disadvantage is that the pressure can bear the bottom and the modulus of elasticity is low. But it's enough in the ballast system. The GRE tube is better than the GRP tube in tensile strength and pressure resistance, so some people refer to the GRE tube as the high-pressure FRP pipe.

- Q: What are the differences between FRP pipes and sand pipes in their uses?

- Glass fiber reinforced plastic sand pipe is mainly used for conveying medium and low pressure water, raw water and sewage.

- Q: What are the advantages of FRP pipes?

- Light weight, corrosion resistance, aging resistance, long service life,

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Ensure the solidification of glass steel products in a reasonable range, in general, glass fibre reinforced epoxy resin material curing degree if the use of amine curing agent, the best curing degree in the range of 135 degrees --150 degrees, polyester resin, Mohs hardness of about 60 is OK.

- Q: What is the thickness of all types of FRP pipes?

- The standard effective length of the tube is 6m and 12M, and the production methods include fixed length winding process, centrifugal casting process and continuous winding process of three kinds. Classification can be carried out according to the product process method, pressure grade PN and stiffness grade SN.

Send your message to us

Composite Pipe (FRP/GRP/GRE) Reinforced Concrete Pipe

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords