Composite Glass Fiber Reinforced Polymer Pipes (RPMP)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

Characteristics

• Corrosion resistance High mechanical property

• Low friction coefficient

• Light weight

• Non toxic

• Maintenance free

• Long life span

• Double O ring sealing joint make the pressurization

more convenient and unique.

• Convenient and quick installation

• Long life of more than 50 years

Production range

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced. Also, we can provide the customized product according to user’s specific requirements.

Technical data

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

1600 | 23.6 | 21.2 | 20 | 26.2 | 23.4 | 22 | 33.7 | 28.2 | 26.9 |

1800 | 26.3 | 23.5 | 22.4 | 29.2 | 26.1 | 24.7 | 36.4 | 31.6 | 30.3 |

2000 | 27.4 | 25.4 | 23.4 | 35 | 32.4 | 29.6 | 44.7 | 37.3 | 36.1 |

2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 41.5 | 40.4 |

2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 44.6 | 42.8 |

2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 47.2 | 45.6 |

2800 | 39.6 | 36.0 | 34 | 49.4 | 45.1 | 42 | 62 | 53 | 51 |

3000 | 41.0 | 38.1 | 36.2 | 52 | 47 | 45.3 | 67 | 58.2 | 54 |

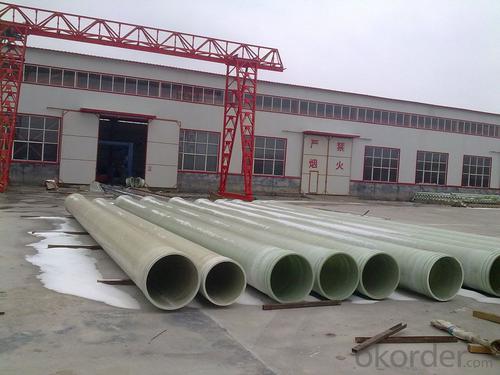

Pictures

- Q: Mending method for glass fiber reinforced plastic pipe

- Other repair methods: choose resin, accelerator, curing agent, high quality glass fiber cloth. Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, the proportion of the curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth for glass steel with a good quick, let the glass steel glass fiber cloth fully soaked, waiting for glass steel fully cured, and then repeated several layers. It will be strong.

- Q: Glass fiber reinforced plastic sand pipe backfill 5m, how much kg pressure?

- These two parameters are based on the need and the actual geological situation to determine, not a backfill a few meters can be determined.

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- This depends on what your medium is, the general food industry requires stainless steel, but the medium contains acidic substances, stainless steel is better than FRP corrosion resistance

- Q: Pipe installation of glass fibre reinforced plastic pipe

- The slope of the pipeline shall be adjusted according to the requirements of the drawing. The adjustment method can be achieved by using the support to reach the slope requirement. The weld shall be located where it is convenient for inspection and observation.

- Q: How to install FRP pipe correctly

- Glass tube and carbon steel pipe connection, at present, the most reliable way of connection is indeed onlyOther, such as on-site bonding, because of the two kinds of material is not the same, the quality of bonding is not very stable!

- Q: Would like to ask about the plastic lined steel pipe, steel pipe, glass steel skeleton, the advantages and disadvantages of each ceramic pipe, to know a friend told, very grateful!

- Steel skeleton pipe is not corrosion resistant, often used in drainage, easy to install, the price is almost the same as fiberglass, cheap inside there is no steel skeleton

- Q: Is it possible to touch the water when the glass fiber reinforced plastic pipe is polished?

- For nearly 20 years of brand silicone mold manufacturers, steel and glass also played nearly 20 years, glass steel pipe interface after grinding with water is Never mind, can be polished with water to the point where you can proceed to the next step of the operation of the glass steel bonding with a clean cotton cloth to wipe clean.

- Q: How many times can the temperature withstand of FRP winding pipes? What are the factors?!

- To see what kind of model and materials, the general performance of FRP and cast iron pipe performance close to the temperature range of 100----420 degrees. Affected by the media, the environment is more. Good luck。

- Q: What is the elastic modulus of glass fiber reinforced plastic?

- Glass fiber reinforced plastics (FRP), also known as GFRP, that is, fiber reinforced plastics, generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastics made from glass fiber or its products are called fiberglass reinforced plastics, or "GRP", and they are distinguished from tempered glass. Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. It is light and hard, non conductive, stable in performance, high in mechanical strength, low in recycling and corrosion resistant. It can be used instead of steel to make machine parts, automobiles, ship shells, etc..

- Q: How long is the service life of glass fiber reinforced plastic pipes?

- The glass fiber reinforced concrete grille is made of three kinds of polypropylene, polyvinyl chloride and ethylene propylene copolymer. The FRP grille is only half the size of the glass, saving transportation, unloading, mounting, and supporting the cost of the frame.

Send your message to us

Composite Glass Fiber Reinforced Polymer Pipes (RPMP)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords