Aluminium Foil for Insulation and Food Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Foil for Insulation and Food Packaging

l Product Introduction

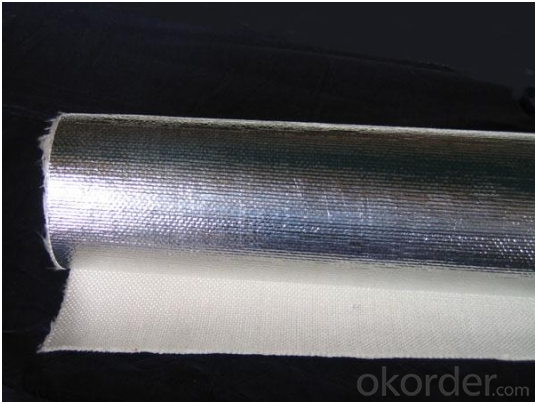

Aluminum foil is widely used for thermal insulation (barrier aand reflectivity), heat exchangers (heat conduction) and cable liners. Aluminum foil's heat conductive qualities make it a common accessory in hookah smoking: a sheet of perforated aluminum foil is frequently placed between the coal and the tobacco, allowing the tobacco to be heated without coming into direct contact with the burning coal.

l Product Description

Name | Aluminum foil for insulation and food packaging |

Application | Building insulation, apartment building, pipework insulation, food packaging |

Alloy Type | 8011, 1050, 1100 |

Tempe | O |

Thickness & Tolerance | 0.01~0.08 mm (Tolerance =±8%) |

Width & Tolerance | 200 -1500mm (Tolerance: 1mm) |

Typical Core I.D. | 76mm, 150mm, 200mm |

Inner Core Materials | Steel, Core, Aluminum core |

Mechanical Properties | Tensile Strength(U.T.S): 40 MPA - 110 MPA |

Elongation≥1% | |

Adopted Standard | GB3198(China National Standard) |

Package: | Seaworthy Export Standard Wooden Box |

Special specifications are available on customer’s requirement. | |

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 30 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

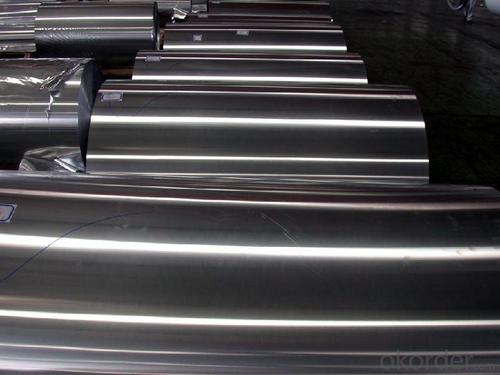

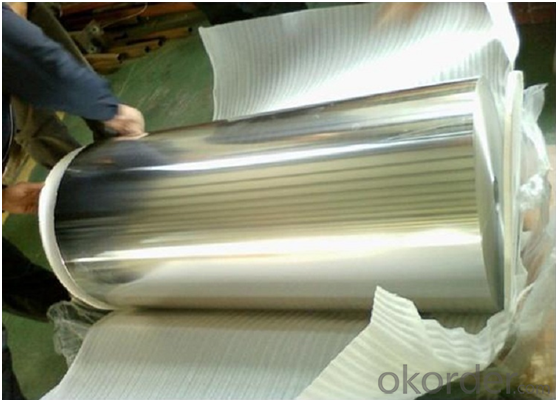

l Products Images and Application

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What is aluminum foil?Can it be decomposed by soil?

- A kind of aluminum rolled into sheets of hot stamping material, the effect of stamping and silver foil stamping similar effects, it is also called the false silver. Because aluminum is soft, ductile, with silver white luster, if after rolling sheet,

- Q: Does the FFC package foil have no grounding, which is equivalent to adding a capacitor to the cable?

- If both ends are not grounded, it should be equivalent to the effect of adding an inductor (somewhat like the use of a magnetic ring).If there is a parasitic capacitor, it exists everywhere, but the size of the parasitic capacitance.

- Q: Relationship between capacitor capacity and aluminum foil

- If it is the gold film capacitor, the medium is the film, the voltage is high, the medium is more, so the capacity is not only related to the area of the aluminum foil, but also to the thickness of the dielectric. Generally speaking, if the voltage is determined, the larger the area of the aluminum foil, the greater the capacity!

- Q: The difference between aluminium foil alloy 1060 and 1235

- The rolling process is rough rolling, rolling, finishing, slitting, annealing and packing. The product has a variety of functions such as aluminum foil, foil, food bags, capacitors etc.. Largest customer - Tetra Pak packaging.

- Q: Must there be foil wrapper in the Tea Caddy?

- This is usually to keep dry, and if the tea itself has been wrapped up in vacuum, then there is no need

- Q: Is there any harm to the pure milk packing aluminum foil in boiling water?

- There is a polythene film (PE film) inside the aluminum foil package. The temperature of the ordinary boiling water is not enough to dissolve and destroy the PE film, and it will not touch the food. The boiling temperature of the water can not reach the melting point of the PE film, and the milk will not touch the aluminum foil, so the aluminum can not be detected. Aluminum is also relatively stable, it is not particularly lively metal, so simply by boiling it, it does not occur chemical reactions, and then into the food. In other words, in the case of packaging in line with national standards, the packaging of boiled milk will not lead to excessive aluminum.

- Q: How do you test the resistance value of the aluminum foil of the capacitor?

- At this time, the use of capacitor aluminum foil after the breakdown will automatically repair features, resulting in a repeated breakdown - repair process, and measurement.

- Q: What can be used to make foil?

- Easy open bottle cap and medicinal aluminum foil PTP drug foil pharmaceutical packaging mainly includes water injection, aluminum foil, aluminum foil because PTP has moisture-proof, portability, safety and sanitation and other advantages, is widely used in the international pharmaceutical industry three, automotive composite foil with rapid development of automobile and aluminum rate of China's automobile industry continues to improve, with the rapid increase of foil market of automobile, automobile foil has two kinds, one is the composite foil used for automobile air conditioner, automobile air conditioner China has aluminum, aluminum foil on the annual demand of 15 thousand tons; the other is a composite foil used for the manufacture of auto radiator, radiator, condenser at present, automobile water tank and an evaporator, the rate of aluminum reached 40%, the annual demand of 3 thousand tons. Four, aluminum foil for electrolytic capacitor electrolytic capacitor used in aluminum foil is a kind of work in polar conditions of corrosive materials, structure of aluminum foil have higher requirements, the aluminum foil is divided into three types: the cathode foil thickness is 0.015mm ~ 0.06mm; high pressure foil thickness is 0.065mm ~ 0.1mm, production requirements using high pure aluminum foil; low voltage foil thickness is 0.06mm ~ 0.1mm.

- Q: Dcgy-500 type aluminum foil sealing machine is out of order, it is not sealed, burned out which element, how to fix?

- Hand held aluminum foil sealing machine operation method:The container with aluminum foil sealing machine alignment sensor head center (previously placed induction aluminum foil container cover and tighten the membrane compaction) click on the handle "induction switch", then the original set time countdown to zero, said the work has been completed, and then remove the head of a container under induction a sealing operation.Check the sealing quality, according to different materials, diameter containers, and production efficiency, and properly trim the "time setting button", so that the sealing quality to the best.

- Q: Where is the use of high pressure etching into electronic aluminium foil?

- In the family of electrolytic capacitors, aluminum electrolytic capacitors are widely used in the world for nearly 20 years because of their high performance, low cost and wide range of uses. Taking Japan as an example, the output of electrolytic capacitor foil was about 3000 tons in 1995. By 2001, the output has reached 70 thousand to 80 thousand tons, almost increasing at an alarming rate.

Send your message to us

Aluminium Foil for Insulation and Food Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords