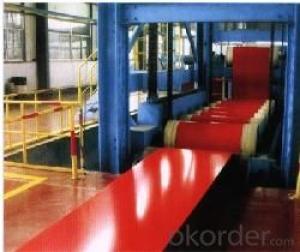

Zinc Coil Galvanized Sheet Prepainted Steel PPGI DX51D SGCC With Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Zinc Coil Galvanized Sheet Prepainted Steel PPGI DX51D SGCC With Best Quality

Specification of the Zinc Coil Galvanized Sheet Prepainted Steel PPGI DX51D SGCC With Best Quality

| NAME | PPGI | GALVANIZED | GALVALUME/ZINCALUME |

| CERTIFICATE | ISO9001:2008 | ||

| STANDARD | EN10142 JIS G3302 GB/T-12754-2006 | ASTM A653M JIS G3302 GB/T2518 EN 10142 | ASTM A792M JIS G3321 JIS G3317 EN 10215 |

| GRADE | CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 | DX51D+Z/DX52D+Z/S250GD+Z S300GD+Z/S350GD+Z/S550GD+Z SGCC/SGCH/SGCD1-SGCD3/SGC340-SGC570 G2+Z/G3+Z/G250+Z/G300+Z G350+Z/G550+Z | DX51D+AZ/DX52D+AZ/S250GD+AZ S300GD+AZ/S350GD+AZ/S550GD+AZ SGLCC/SGLCD/SGLC300-SGLC570 G2+AZ/G3+AZ/G250+AZ/G300+AZ G350+AZ/G550+AZ |

| COATING | RAL COLOURS | Z60g/m2 to Z275g/m2 | AZ30g/m2 to AZ150g/m2 |

| SIZE | (0.13mm-1.5mm)X1000mm OR as requirements | (0.13mm-4.0mm)X1500mm OR as requirements | (0.12mm-4.0mm)X1500mm OR as requirements |

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled -galvanized | Hot rolled-cold rolled -galvalume /Aluzinc |

| SURFACE TREATMENT | Mini/regular/big/zero spangle,Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLER SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle,Chromate treatment /chromate-free treatment /untreated unoile/oiled,TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint,Coating | |

| APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds; Outer clad sheets for washing machine, refrigerator, televi-sion, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts; Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in high -way; Electric control cabinet, industrial refrigeration equipment, automatic vending machine; Wear resistant steel, high- strength - steel plate | ||

Supplier of the Zinc Coil Galvanized Sheet Prepainted Steel PPGI DX51D SGCC With Best Quality

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Delivery of the Zinc Coil Galvanized Sheet Prepainted Steel PPGI DX51D SGCC With Best Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to the weldability of products?

- The weldability of products is improved in various ways by special steel. Firstly, special steel is designed specifically to have enhanced weldability characteristics, making it easier for welders to join different pieces of steel. This is achieved by carefully controlling the chemical composition of the steel, ensuring that it contains the necessary alloying elements and impurity levels to promote good weldability. Secondly, special steel often has a lower carbon content compared to regular steel, reducing the likelihood of weld metal cracking. Carbon is known to increase the susceptibility to cracking during welding, so by decreasing the carbon content, special steel reduces this risk, resulting in a stronger and more durable weld joint. Furthermore, the weldability of special steel is improved by controlling the grain size and microstructure. Fine-grained steel exhibits better toughness and reduced brittleness, making it less prone to cracking during welding. Similarly, a well-controlled microstructure ensures a more uniform distribution of alloying elements, leading to improved mechanical properties and weldability. To further enhance its weldability, special steel often undergoes various heat treatment processes. Annealing, normalizing, or quenching and tempering can refine the microstructure, relieve residual stresses, and improve the toughness of the steel, all of which contribute to better weldability. In addition, special steel is carefully manufactured to have low levels of impurities, such as sulfur and phosphorus, which can negatively affect weldability. By minimizing these impurities, the steel can be welded without the formation of detrimental welding defects, ultimately improving the overall quality of the weld. In conclusion, special steel plays a crucial role in enhancing the weldability of products. Its carefully controlled chemical composition, reduced carbon content, controlled grain size and microstructure, as well as the application of heat treatments, all contribute to easier, stronger, and more reliable weld joints.

- Q: How does stainless steel contribute to the automotive industry?

- Stainless steel contributes to the automotive industry by providing strength, durability, and corrosion resistance in various automotive components such as exhaust systems, body panels, and engine parts. Its ability to withstand extreme temperatures and harsh conditions make it a preferred material for manufacturing high-performance vehicles. Additionally, stainless steel's aesthetic appeal and low maintenance requirements make it suitable for decorative purposes in car interiors and exteriors.

- Q: What is the impact of manganese in special steel alloys?

- The presence of manganese in special steel alloys is crucial as it greatly affects their properties and performance. These alloys, also referred to as high-strength or low-alloy steels, are specifically designed to possess improved mechanical properties, including increased strength, durability, and resistance to wear and corrosion. In order to achieve these desired characteristics, manganese, along with other alloying elements such as nickel, chromium, and molybdenum, is incorporated into the steel. One of the major impacts of manganese in special steel alloys lies in its capacity to enhance the hardenability of the steel. During the solidification and cooling process, manganese promotes the formation of fine-grained structures, which ultimately leads to improved strength and toughness. This particular property is of utmost importance in applications where the steel needs to endure heavy loads, shocks, or extreme temperatures. Moreover, manganese aids in reducing the brittleness of the steel and improving its weldability. By forming a solid solution with iron, it prevents the formation of detrimental iron sulfides, which can cause brittleness and hinder the steel's weldability. Consequently, manganese becomes an essential element in steels utilized in various industries such as fabrication, construction, and automotive, where welding is a common practice. In addition, manganese contributes to the steel's resistance against corrosion and oxidation. It creates a protective oxide layer on the surface of the steel, effectively preventing the intrusion of oxygen and moisture. This particular property proves to be highly advantageous in industries where the steel is exposed to harsh environments or corrosive substances, such as marine applications, chemical processing plants, or oil and gas refineries. Furthermore, manganese enhances the hardenability and wear resistance of the steel, making it suitable for the production of tools, machinery parts, and cutting edges. It heightens the steel's ability to undergo heat treatment, thus enabling the attainment of desired hardness and strength through processes like quenching and tempering. In conclusion, the inclusion of manganese in special steel alloys significantly enhances their hardenability, weldability, toughness, corrosion resistance, and wear resistance. Its addition enables the production of high-strength and durable materials capable of withstanding demanding applications and environments.

- Q: What are the main factors affecting the heat resistance of special steel?

- The heat resistance of special steel is determined by several key factors, including its alloy composition, microstructure, and heat treatment. The addition of specific elements like chromium, nickel, molybdenum, and tungsten can enhance the steel's ability to withstand high temperatures by forming stable oxide layers on its surface, which protect against oxidation and corrosion. The microstructure of special steel also plays a role in its heat resistance. Factors like grain size, phase distribution, and the presence of precipitates can affect the steel's thermal stability. Fine-grained structures and a homogeneous phase distribution improve resistance to creep, while precipitates like carbides or intermetallic compounds strengthen the steel and prevent thermal softening. Heat treatment processes, such as quenching and tempering, have a significant impact on the heat resistance of special steel. Proper heat treatment optimizes the microstructure and enhances mechanical properties, including resistance to thermal degradation. Controlled quenching, for example, promotes the formation of a martensitic structure, which increases hardness and strength at high temperatures. Other factors that influence heat resistance include impurities, surface conditions, and environmental factors. Impurities like sulfur and phosphorus can reduce resistance to high temperatures by promoting brittle phase formation or oxidation. Surface conditions, such as roughness or cracks, can cause localized heating and accelerated degradation. Environmental factors like corrosive gases or high humidity can also promote oxidation or corrosion. In conclusion, the heat resistance of special steel is affected by alloy composition, microstructure, heat treatment, impurities, surface conditions, and environmental factors. Understanding and optimizing these factors are crucial for developing special steel with superior heat resistance for various industrial applications.

- Q: Can special steel be used in the paper manufacturing industry?

- Yes, special steel can be used in the paper manufacturing industry. It is commonly used for the construction of machinery and equipment such as rollers, blades, and cutting tools, due to its high strength, durability, and resistance to wear and corrosion. Special steel can also be used for the production of paper mill rolls, which are essential for the processing and production of paper.

- Q: What are the mechanical properties of special steel?

- Enhanced mechanical properties are possessed by special steels, also known as alloy steels, in comparison to regular carbon steels. These properties differ based on the concentration and specific alloying elements. Some common mechanical properties of special steel are as follows: 1. High tensile strength: Special steels are recognized for their exceptional strength, making them suitable for applications requiring high load-bearing capacity. The tensile strength of these steels can vary from 500 MPa to over 2,000 MPa, depending on the composition. 2. Improved hardness: The inclusion of alloying elements in special steels can significantly increase their hardness. This property is desirable for applications that demand resistance to wear and abrasion. Special steels can achieve hardness levels ranging from 200-600 HB (Brinell hardness), depending on the specific alloy composition and heat treatment. 3. Good toughness: Special steels commonly exhibit good toughness, which refers to their ability to absorb energy before fracturing. This property is crucial for components subjected to impact or dynamic loading. The combination of high strength and toughness makes special steels suitable for demanding applications such as automotive parts or industrial machinery. 4. Excellent fatigue resistance: Special steels are engineered to withstand cyclic loading without failure. They display enhanced fatigue resistance, enabling them to endure repeated stress cycles without compromising their structural integrity. This property makes special steels ideal for critical components in the aerospace, automotive, and machinery industries. 5. Superior corrosion resistance: Depending on the alloy composition, special steels can offer improved corrosion resistance compared to regular carbon steels. The addition of elements like chromium, nickel, or molybdenum aids in the formation of protective oxide layers on the surface, preventing corrosion and increasing durability. 6. High temperature resistance: Certain special steels are specifically formulated to perform well at elevated temperatures. They possess excellent heat resistance and can retain their mechanical properties even under extreme temperatures. This property is crucial for applications such as turbine blades, exhaust systems, or high-temperature furnaces. It is important to note that the specific mechanical properties of special steel can vary significantly depending on the specific alloy composition, heat treatment, and processing techniques employed. Therefore, it is essential to consult the material specifications or seek expert advice to determine the exact mechanical properties of a particular special steel.

- Q: What are the cutting tools used for machining special steel?

- The cutting tools commonly used for machining special steel include carbide inserts, high-speed steel (HSS) drills and end mills, ceramic inserts, and diamond-coated tools. These tools are designed to withstand the high temperatures and hardness of special steel, ensuring precise and efficient cutting.

- Q: What are the different methods of improving the impact toughness of special steel?

- There are several methods for improving the impact toughness of special steel. One common method is through heat treatment processes such as quenching and tempering, which involve heating the steel to a high temperature and then rapidly cooling it. This helps to refine the grain structure of the steel, making it more resistant to cracking and improving its toughness. Another method is alloying, where specific elements are added to the steel to enhance its toughness, such as nickel, chromium, or manganese. Additionally, controlling the cooling rate during the manufacturing process, known as controlled cooling, can also improve the impact toughness of special steel by minimizing the formation of brittle phases. Overall, a combination of heat treatment, alloying, and controlled cooling can be employed to enhance the impact toughness of special steel.

- Q: What are the different methods of surface electroplating for special steel?

- There are several methods of surface electroplating for special steel, including electroless plating, electroplating by immersion, barrel plating, and rack plating. Electroless plating is a chemical process that uses a reducing agent to deposit a layer of metal onto the steel surface. Electroplating by immersion involves immersing the steel in an electrolyte bath and applying an electric current to deposit a metal coating. Barrel plating is a method where the steel parts are placed in a rotating barrel along with the plating solution, creating a tumbling action that ensures an even coating. Rack plating involves suspending the steel parts on a rack and immersing them in the plating bath. Each method has its own advantages and is chosen based on the specific requirements and characteristics of the special steel being plated.

- Q: What are the different surface hardening grades of special steel?

- There are several different surface hardening grades of special steel, each designed to provide specific characteristics and properties. Some of the commonly used grades include: 1. Case-hardening steels: These grades are typically low carbon steels that are designed to develop a hard outer layer, or case, while maintaining a softer core. This is achieved through processes like carburizing or nitriding, which introduce carbon or nitrogen into the surface of the steel. Case-hardening steels are often used in applications where wear resistance and toughness are required. 2. Tool steels: These grades are specifically designed for use in cutting, forming, and shaping tools. Tool steels are known for their high hardness, resistance to wear, and ability to retain their cutting edge even at elevated temperatures. Various types of tool steels are available, such as high-speed steel (HSS), hot work steel, cold work steel, and plastic mold steel, each suitable for specific applications. 3. Stainless steels: These grades of special steel contain a minimum of 10.5% chromium, which provides excellent corrosion resistance. Stainless steels can be hardened through processes like precipitation hardening or martensitic transformation. They are commonly used in industries such as food processing, chemical, and medical, where resistance to corrosion and high temperatures are crucial. 4. High-strength steels: These grades are designed to provide exceptional strength and toughness. They often contain alloying elements like manganese, chromium, or nickel to enhance their mechanical properties. High-strength steels are commonly used in structural applications, automotive components, and heavy machinery. 5. Maraging steels: These grades of special steel are known for their high strength, toughness, and excellent resistance to fracture. Maraging steels achieve their properties through a unique aging process, which involves a precipitation-hardening treatment. They find applications in aerospace, defense, and tooling industries. 6. Bearing steels: These grades are specifically formulated to provide excellent wear resistance and durability for use in bearing applications. Bearing steels often contain alloying elements like chromium, molybdenum, and vanadium to enhance their mechanical properties and resistance to fatigue. These are just a few examples of the different surface hardening grades of special steel. Each grade offers unique properties and characteristics, allowing for a wide range of applications in various industries.

Send your message to us

Zinc Coil Galvanized Sheet Prepainted Steel PPGI DX51D SGCC With Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords