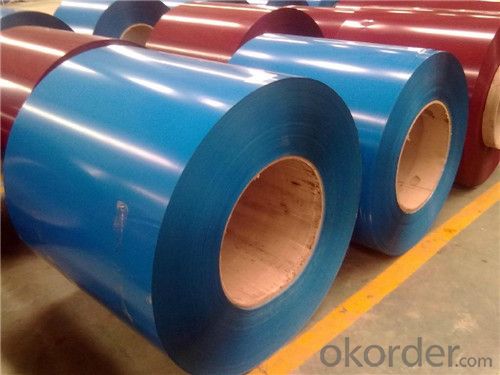

Z31 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z31 BMP Prepainted Rolled Steel Coil for Construction

Description of Z31 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel coil means that steel coils has gone through a chemical process.

To keep it from corroding, so this protective metal, zinc layers, does not get rusty as easily. The coating also gives the steel a more durable, hard to scratch finish.Strict procurement process---skillful technical workers---final products inspection

(resistance to corrosion, salt spray test, exposure test, machinability, thermal resistance)

Main Feature of Z38 BMP Prepainted Rolled Steel Coil for Construction

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3. Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North American, the Middle East, the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

Applications of Z38 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z31 BMP Prepainted Rolled Steel Coil for Construction

Product | Z31 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z31 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils inspected for surface cleanliness?

- Steel coils are inspected for surface cleanliness through various methods such as visual examination, ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help identify any surface defects, contaminants, or irregularities on the steel coil, ensuring it meets the required cleanliness standards.

- Q: What is the best butcher's steel around $20? I'm looking for a good tool to straight out some kitchen knives. thanks

- Not really. Unless your knives are remarkably rusty and chipped, cleaning the knife after the steel will do little. It is possible that you are consuming an immeasurable amount of metal, but then again you're probably consuming a little from everything the food touches. Thats just the way it is and it is nothing to be worried about.

- Q: How are steel coils unloaded from a truck?

- Steel coils are typically unloaded from a truck using specific equipment and a well-coordinated process. The unloading process involves several steps to ensure the safe and efficient removal of the steel coils. Firstly, a forklift or crane is typically used to reach inside the truck bed and secure the steel coil. The forklift or crane operator carefully positions the lifting apparatus underneath the coil, ensuring that it is centered and balanced. Once the steel coil is properly secured, the forklift or crane slowly lifts it out of the truck bed while maintaining stability. The operator must be cautious and consider factors such as the weight and dimensions of the coil to prevent any accidents or damage. After the steel coil is lifted out of the truck, it is usually placed onto a designated area such as a flatbed trailer, storage rack, or directly onto the ground. If placed on the ground, protective measures such as wooden blocks or rubber mats are often used to prevent any damage to the coil or the surface it is placed on. In some cases, steel coils may be unloaded using a specialized coil trailer, which is equipped with hydraulic systems to tilt the trailer bed and roll the coil off. This method is particularly useful for unloading larger and heavier coils. Overall, unloading steel coils from a truck requires skilled operators, appropriate lifting equipment, and adherence to safety protocols. It is essential to follow these steps meticulously to ensure the safe and efficient unloading of steel coils.

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: How are steel coils used in the manufacturing of exhaust manifolds?

- Steel coils are used in the manufacturing of exhaust manifolds by being shaped and formed into the desired design and dimensions of the manifold. The coils are typically cut, bent, and welded together to create the necessary shape and structure of the exhaust manifold.

- Q: I bought a Remington 870 super mag last fall and wanted to to switch to non-tox steel loads. The gun came with a modified rem choke. I know that not all chokes are qualified to handle steel. It doesn't say anywhere on the choke no steel I was just wondering if anyone out there knew for sure that those chokes that the guns come with won't get damaged be steel.

- No problem. With steel shot you would use one choke size LARGER. If you want a full choke type pattern ( 70 % in a 30 inch circle at 30 yards ) you use a modified choke. if you want a modified pattern use the improved cylinder. Don't use the full or extra full. This is because when using lead shot it deforms, and fits through the choke, steel shot does not deform, it remains rigid. The first indication of a problem will be a slight bulge in the barrel right behind the choke. Check that once in a while, if you ever have that problem, it is not drastic if caught early. Today's modern shotguns all have been set up for steel shot. The old ones such as Belgium Brownings, are a no go. Funny thing, when we first began importing steel shot, I asked a Browning Tech guy if he thought I could fire steel out of my Belgium Browning. He said not a good idea, however, if you have the Citori or other Japanese made Brownings, no problem. Hummm, my expensive Brownings, no, but Japanese made OK, this is because the Japanese steel was higher quality. Geeeze. I was shocked.

- Q: Can steel coils be stored outdoors?

- Yes, steel coils can be stored outdoors, but it is not recommended for long-term storage. Outdoor storage exposes the coils to the elements, which can lead to corrosion and other forms of damage. It is preferable to store steel coils indoors or in covered areas to ensure their longevity and protect them from environmental factors.

- Q: How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems by being formed into sheets or strips, which are then shaped and welded to create the framework and shelves of the storage units. The high strength and durability of steel make it an ideal material for supporting heavy loads and ensuring the longevity of storage systems.

- Q: I have samurai sword that is a replica of the kill bill sword. It says on the blade stainless steel, what can i use to shine and protect blade. It had and still does a wax.like coating on the blade sine i received it. Thx for ur help

- Normally okorder

- Q: Does anyone know what colour steel is?How hard steel is?The density of steel?Conductivity of steel? (Heat and electricity)Reactivity of steel?Melting and boiling points of steel?And the malleability and ductility of steel?Ive looked all over the net and i cant find anything. Can someone please answer these questions or give me a website?THANKS!

- I'm really finding it hard to believe that you've look all over the net and can't find out anything about steel. A Google search on steel turns up 270 MILLION hits, with the first being good, ole, Wikipedia. A quick glance down the article shows up much of what you want. But keep in mind that that steel is not a single substance. There are many different kinds of steels and each has its own properties. Obviously, steel is a metal, so it is a good conductor of heat and electricity. It can be drawn into wires, so it is ductile. It's hard. It's harder than iron. That's the whole point for making steel. The boiling point and freezing points will depend on the type of steel. But please don't insult us by saying you can't find anything about steel. That simply can't be true.

Send your message to us

Z31 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords