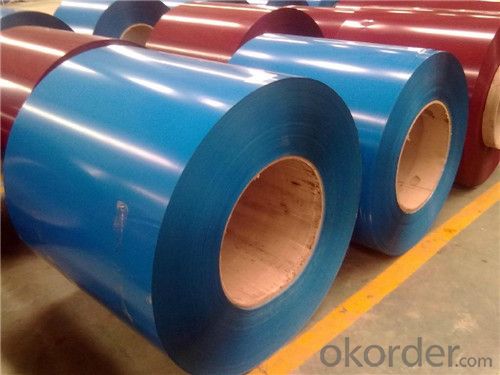

Z38 Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z38 Prepainted Rolled Steel Coil for Construction

Description of Z38 Prepainted Rolled Steel Coil for Construction

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of Z38 Prepainted Rolled Steel Coil for Construction

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of Z38 PPGI Prepainted Rolled Steel Coil for Construction

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards

Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door of garage\Roller shutter door\Persian blinds\Cabana and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\\Folding screen\Ceiling\Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Specifications of Z38 Prepainted Rolled Steel Coil for Construction

Product | Z38 Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z38 Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: what is the differance between ceramic and stainless steel headers and 4-2-1 and 4-1 and which are better for racing and should i get ceramic or stainless steel headers???? for a 98 civic

- 1) okorder ... The top two are of 4-1 design. Good luck, have fun.

- Q: How are steel coils used in the production of marine vessels?

- Steel coils are extensively used in the production of marine vessels due to their strength, durability, and versatility. These coils are typically made of high-quality steel, which is known for its ability to withstand harsh marine environments and resist corrosion. One of the primary applications of steel coils in the production of marine vessels is for the construction of the hull. The steel coils are formed into plates, which are then welded together to create the hull structure. The strength of these coils ensures that the hull can withstand the extreme forces and pressures experienced during a vessel's operation, including rough seas and heavy cargo loads. Additionally, steel coils are used in the production of various components and fittings within a marine vessel. These coils can be shaped, cut, and formed into different parts, such as bulkheads, decks, and superstructures. The versatility of steel allows manufacturers to create complex shapes and structures that are essential for the efficient and safe operation of a marine vessel. Moreover, steel coils are also used for the fabrication of pipes and tubing systems within marine vessels. These pipes are crucial for various functions, such as transporting fluids, fuel, and ventilation throughout the vessel. The strength and corrosion resistance of steel coils ensure that these pipes can withstand the high pressures and corrosive nature of marine environments. Furthermore, steel coils are utilized in the production of marine vessel equipment, such as winches, cranes, and anchor systems. These components require a high-strength material that can withstand heavy loads and constant use. Steel coils provide the required strength and durability to ensure the reliable performance of these critical equipment. In conclusion, steel coils play a vital role in the production of marine vessels. Their strength, durability, and versatility make them an ideal material for constructing the hull, manufacturing various components, fabricating piping systems, and creating equipment. The use of steel coils ensures the safety, efficiency, and longevity of marine vessels, enabling them to navigate the challenging conditions of the open seas.

- Q: What are the dimensions of steel coils used in the metal furniture industry?

- The dimensions of steel coils used in the metal furniture industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width.

- Q: What is the average turnaround time for processing steel coils?

- The average turnaround time for processing steel coils varies depending on several factors such as the size, complexity, and specific requirements of the coils. However, it typically ranges from a few days to a couple of weeks.

- Q: What are the different methods of coil cutting for steel coils?

- There are several methods of coil cutting for steel coils, each with its own advantages and suitability for different applications. Here are some of the common methods: 1. Slitting: Slitting is the most commonly used method for coil cutting. It involves passing the steel coil through a set of rotating circular blades that cut the coil into narrower strips. This method is suitable for producing narrow width strips with precise dimensions. 2. Shearing: Shearing is another method used for coil cutting, especially for thicker gauge coils. It involves using a straight blade to cut the coil along a straight line. Shearing is suitable for producing larger width strips and is often used for heavier gauge steel coils. 3. Laser Cutting: Laser cutting utilizes a high-powered laser beam to cut through the steel coil. This method offers a high degree of precision and can be used to cut complex shapes and patterns. Laser cutting is often used for specialized applications where accuracy and fine details are crucial. 4. Waterjet Cutting: Waterjet cutting involves using a high-pressure jet of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can be used for cutting various materials, including steel. Waterjet cutting is suitable for producing clean and precise cuts without heat-affected zones. 5. Plasma Cutting: Plasma cutting utilizes a high-temperature plasma arc to melt through the steel coil. This method is efficient and can be used for cutting thick gauges of steel. Plasma cutting can achieve high cutting speeds, making it suitable for industrial applications. 6. Guillotine Cutting: Guillotine cutting involves using a guillotine-like mechanism to cut through the steel coil. The coil is placed on a table, and a blade descends vertically to cut through it. Guillotine cutting is suitable for producing straight and accurate cuts with minimal burrs. The choice of coil cutting method depends on various factors such as the desired width and thickness of the strips, required precision, production volume, and the specific application. It is important to consider these factors and consult with experts to determine the most suitable coil cutting method for a particular steel coil.

- Q: I was wondering if steel cases can be loaded to the same pressure as brass cases. Are the cartridges that commonly feature steel cases like the Russian 5.45x39, 7.62x39 and 7.62x54R loaded to a lower pressure than their C.I.P. MAPs (380 MPa, 355 MPa, 390 MPa --gt; 51,488 psi to 56,564 psi)? There must be a reason why most NATO armies use brass cases...

- Steel cases are harder to manufacture, but cheaper in material. Loaded? Yes. Those cases are a very mild steel, and will 'flow' well enough to seal at the pressures involved. The question might come up with low pressure loads though. RE-loaded?? - I wouldn't try it, even if they weren't berdan primed.

- Q: How are steel coils used in the manufacturing of intake manifolds?

- Steel coils are used in the manufacturing of intake manifolds as they are typically shaped and formed into specific geometries to create the necessary channels and passages for the intake air to flow through. These coils are cut, bent, and welded to form the desired shape of the intake manifold, which plays a crucial role in directing and distributing air to the engine cylinders, ultimately optimizing combustion and improving engine performance.

- Q: What is the average lead time for receiving replacement steel coils?

- The average lead time for receiving replacement steel coils can vary depending on various factors such as supplier availability, shipping logistics, and order requirements. However, it is common for lead times to range from a few days to several weeks. It is advisable to contact the specific supplier or manufacturer for accurate and up-to-date information on lead times.

- Q: How are steel coils used in the production of agricultural fencing?

- Steel coils are used in the production of agricultural fencing as they are transformed into wires that are woven, welded, or twisted to create durable and sturdy fences. These steel coils are typically made from high-quality steel, which ensures strength and longevity, making them ideal for withstanding the demands of agricultural environments.

- Q: Can steel coils be used in the production of packaging materials?

- Yes, steel coils can be used in the production of packaging materials. Steel coils are often used as the core material for packaging materials such as metal strapping and steel banding. These coils are strong, durable, and provide excellent tensile strength, making them ideal for securing and protecting various products during transportation and storage. Additionally, steel coils can be easily shaped and formed into different packaging components, ensuring a secure and reliable packaging solution for a wide range of industries.

Send your message to us

Z38 Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords