Z34 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

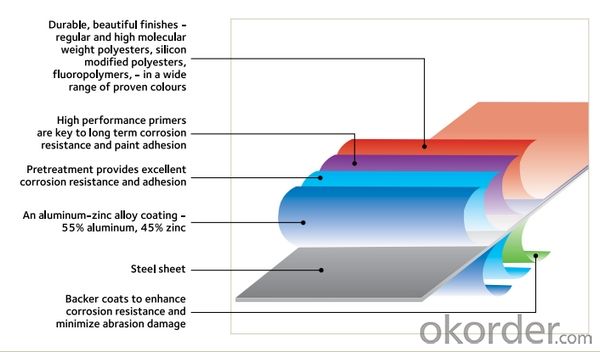

Structure of Z34 BMP Prepainted Rolled Steel Coil for Construction

Description of Z34 BMP Prepainted Rolled Steel Coil for Construction

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Z34 BMP Prepainted Rolled Steel Coil for Construction

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Z34 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z34 BMP Prepainted Rolled Steel Coil for Construction

Product | Z34 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z34 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: I was reading about the Colt 38 Super Custom and it said it's optional between a carbon steel frame or a stainless steel frame. What is the difference? There is also a choice between aluminium or stainless steel hammers and triggers can you also tell me the difference between them please?

- Carbon steel will corrode much more easily than stainless steel, and stainless can be made stronger than carbon steel. Stainless steel is also usually heavier than carbon steel, which helps to control recoil when the gun is fired (recoil is not eliminated, only reduced). Stainless steel can also be polished to a mirror finish, so it doesn't have to be chrome-plated for that shine. Probably the biggest plus to using stainless over carbon steel, though, is the fact that it is far less prone to crystalization than carbon steel. When steel crystalizes, it becomes brittle, and can break at the worst possible times. Bad thing about stainless: It generally costs more. Aluminum is much lighter than any steel, size-for-size, and can be just as strong, if not stronger, than steel; I've worked with aluminum alloys that require special-made tooling. The difference, besides the weight issue, is that aluminum (even most alloys) will become softer when it is heated to a specific point -- which is why it is not used for the barrels of firearms using explosive powders as the propellent source. Because of the cost of the alloys which can withstand the heat generated in the barrel of a firearm, it is just less expensive to use a steel barrel. And for a fella that is so pro-gun, the previous answerer sure seems ignorant of 'em.

- Q: I've seen on TV that stainless steel laminate sheets can be purchased and and used to cover appliances to give it a faux stainless steel look. They mentioned it was important to not have any bubbles (of course) and to work slowly. It's easy to do on a dishwasher, but what about the fridge? The handles are in the way? Do you have to take the handles off? Can anyone find a tutorial for me?

- There okorder appliance paint 2. What you are referring to really is not laminate steel sheets, it's actually more along the lines of shelf liner paper looks like steel with sticky back film that you peel and stick. Place against product and begin to peel down slowly using squeegee or credit card to smooth out bubbles.Sheets can be purchased rangingin size on OKorder for $9.99 + dependent on size. Called stainless steel appliance film can buy a roll for $60.00 on OKorder (normally sells for $100.00) one roll will cover 3 average sized kitchen appliances. Hope this helps!

- Q: Will a stainless steel mesh screen scratch a titanium cup, or vice versa?I have a titanium french press and am thinking about replacing the included press with an all steel one. I am worried about little flakes of titanium or steel getting ground off into the coffee when the press slides in and out. The original press has a polyester cloth for a screen, so nothing scratches.

- Will Titanium Scratch

- Q: What are the main factors that affect the quality of steel coils?

- The main factors that affect the quality of steel coils include the composition and purity of the steel used, the manufacturing process and techniques employed, the temperature and time of the heat treatment, the level of mechanical stress and strain during rolling and cooling, and the presence of any impurities or defects in the final product.

- Q: How can the quality of steel coils be ensured?

- The quality of steel coils can be ensured through a combination of careful selection of raw materials, closely monitored manufacturing processes, and rigorous quality control measures. This includes conducting regular inspections and tests at various stages of production to ensure that the steel coils meet the required specifications and standards. Additionally, implementing proper storage and handling procedures, as well as adhering to industry best practices, can help maintain the quality of steel coils throughout their lifecycle.

- Q: Can steel coils be used in the food processing industry?

- Yes, steel coils can be used in the food processing industry. Steel coils are often used to manufacture a wide range of food processing equipment such as conveyor belts, food storage tanks, mixing tanks, and processing machinery. Steel is a durable and hygienic material that is resistant to corrosion, making it suitable for use in food processing environments. Additionally, steel coils can be easily cleaned and sanitized, ensuring the safety and cleanliness of the food processing equipment. Overall, steel coils are a commonly used material in the food processing industry due to their strength, durability, and compatibility with food safety standards.

- Q: What are the different grades of steel coils?

- There are several different grades of steel coils, including low carbon steel, medium carbon steel, high carbon steel, stainless steel, and galvanized steel. Each grade has its own unique properties and is used for specific applications based on factors such as strength, corrosion resistance, and formability.

- Q: How are steel coils annealed for improved properties?

- Steel coils are annealed for improved properties through a process called annealing. This involves heating the steel coils to a specific temperature and then slowly cooling them to relieve internal stresses and create a more uniform and refined grain structure. This annealing process helps improve the steel's ductility, hardness, and overall strength, making it more suitable for various applications.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing moisture from coming into contact with the steel and causing corrosion. Additionally, the coils may be stored in a controlled environment with low humidity levels to further protect them.

- Q: Are Steel buildings Fire Resistant, just want to know as I am going to owe it . Suggestions required…………..

- A true structural steel building is composed of steel columns, steel bar joist,steel purlins,steel roof frames,and steel siding. This is all load bearing structural steel. The vulnerable area of a steel building is the exposure of this steel to extreme temps during a fire. Steel becomes weak at high temps and begins to twist and distort like a noodle in hot water. Most all steel buildings now are specified by the architect/engineer to have fire retardant spray applied to the key components to protect against high heat during a fire. Even with that some beams/columns are also wrapped with several layers of type x fire rated drywall. Multi story steel buildings usually have lightweight concrete poured over steel decking for all floors above the ground floor. Any and all penetrations in these concrete floors must be sealed around to stop fire and smoke from spreading from one floor to the next, and fire rated doors at all stairways to each floor. Even ductwork that runs to other floors must have fire rated dampers that close if signaled by a sensor, this stops smoke/fire from spreading through the ductwork. Sprinkler systems are usually required in new structures that exceed at pre-determined square footage by the state you are in. Hope this helps you out.

Send your message to us

Z34 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords