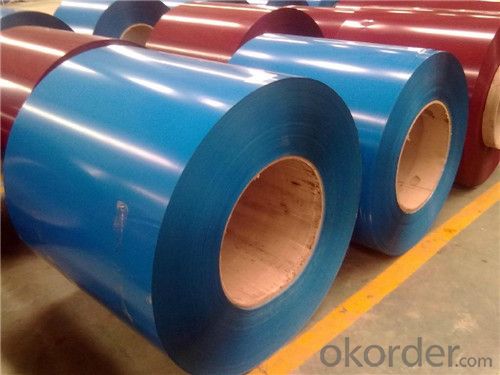

Z38 BMP Prepainted Rolled Steel Coil for Roofing Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z38 BMP Prepainted Rolled Steel Coil for Roofing Construction

Description of Z38 BMP Prepainted Rolled Steel Coil for Roofing Construction

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of Z38 BMP Prepainted Rolled Steel Coil for Roofing Construction

1. Certificate: ISO, BV, CE, SGS,SAI,SGS Approved

2. Feedback within 8 hours

3. Best price based on good quality from our own factory

4. Quick delivery and waterproof standard export packing

5. Stock and production are both available

6. Cooperation with NING STEEL and JIANLONG STEEL

7. Experience for many years, specilized in manufacturing and exporting

8. Customers from many continents, such as North America, South America, Europe, Africa, etc

9. Flexible payment with T/T,L/C,Kunlun bank .

Applications of Z38 BMP PPGI Prepainted Rolled Steel Coil for Roofing Construction

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards

Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Specifications of Z38 BMP Prepainted Rolled Steel Coil for Roofing Construction

Product | Z38 BMP Prepainted Rolled Steel Coil for Roofing Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z38 BMP Prepainted Rolled Steel Coil for Roofing Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- i have steel and i like the way it sounds but i like nylon better

- Q: How are steel coils used in the production of agricultural systems?

- Due to their durability and strength, steel coils are frequently employed in the production of agricultural systems. Specifically, these coils are commonly utilized in the creation of machinery and equipment essential for agricultural operations. One prevalent use of steel coils lies in the manufacture of farming machinery such as tractors, plows, and cultivators. These machines necessitate robust components capable of enduring the challenging conditions present in the agricultural environment. Steel coils are employed to fabricate the frames, chassis, and other structural parts of these machines, providing the necessary strength and support. Additionally, steel coils are employed in the creation of irrigation systems, which play a crucial role in efficient water management within agriculture. These coils are employed in the construction of pipes, valves, and fittings, ensuring the durability and long-lasting nature of the irrigation system. Furthermore, steel coils are employed to fabricate storage tanks and silos, which serve as vital tools for storing and preserving agricultural products like grains, seeds, and fertilizers. Moreover, steel coils find application in the construction of greenhouses and agricultural buildings. These coils are used to fabricate the structural framework, providing stability and resistance against environmental factors. Steel coils are also employed in the production of fencing and enclosures to safeguard crops and livestock from external threats. In conclusion, steel coils play a significant role in the production of agricultural systems by delivering the necessary strength, durability, and stability required for farming machinery, irrigation systems, storage facilities, and agricultural structures. Their utilization ensures that these systems can withstand the demanding conditions of the agricultural industry and contribute to efficient and sustainable farming practices.

- Q: What are the different types of steel alloys used in coil manufacturing?

- There are several types of steel alloys used in coil manufacturing, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. Each alloy has different characteristics and properties that make it suitable for specific applications in coil manufacturing. Carbon steel is commonly used for general-purpose coils due to its affordability and versatility. Stainless steel is preferred for its corrosion resistance and aesthetic appeal, making it suitable for applications that require durability and a polished finish. HSLA steel, on the other hand, offers enhanced strength and toughness, making it ideal for demanding applications that require high performance and durability.

- Q: like building steel beams. i'm pretty sure with a sawzall.

- Yes, you can use a Sawzall. A ban saw or a cutting torch work too. But a cutting torch woudl leave a pretty rough edge.

- Q: All of my friends say that if a car made of mostly carbon fiber would crash into a full steel car, or vice versa, the steel car would be DESTROYED and the carbon fiber would drive away, if not, easily repairable.

- At a reasonably high speed, both cars would be undrivable. That's by design, not due to the strength/weakness of the materials. The energy in an impact needs to go somewhere. Cars are designed so the body and the frame will bend and break, reducing the impact on the occupants. If the car is too rigid the chances of the occupants being injured increases. Carbon fiber composites do have a better strength to weight ratio than steel but they're also a lot less dense, so the same volume of material will have a similar strength. The primary benefit to carbon fiber is that for a part of the same strength the carbon fiber part will weigh less than the steel part.

- Q: Hello people.Me and the life mate have been working on a fantasy book together and we are currently in the process of outlining the cultures. The culture of our antagonists' is a sort of woodland tribal/celtic[ish] deal and they are very nature oriented. Being a detail freak and wanting to have some real world credibility in the story, I am trying to decide how they produce steel. I want steel to be an important part of the culture, but a thing that is in limited supply. I also do not want there to be a large amount of resources committeded to mining or processing iron ore for steel. So does anyone have any real world ideas explaining how the people can produce steel without using underground mining operations, large processing facilities, and without raping the land?All help and ideas are appreciated

- Well, steel is just modified iron, so you're going to have to start with acquiring the iron first. For that, you're most likely going to be using some sort of underground mining somewhere - either they do that themselves, or they purchase the iron elsewhere. Assuming you're not dealing with meteoric iron (which is possible, but pretty uncommon), or iron sands (not likely in a woodland area), then unless you're dealing with a rocky outcropping with iron veins out in the open, I'm pretty sure there needs to be somebody doing some digging. That said, it doesn't need to be a full raping of the land scenario. A couple of minor mines, some small-scale smelting operations, and somebody knowing the secret of making steel, and it could give you small amounts of steel without making an ecological disaster.

- Q: I need to know how you rate the hardness of steel any ideas?

- Find your portable hardness testers from our latest collections thats for sure having the ability to test hardness of metal alloys and plastic by applying some amount of pressure on it. All our evaluators can evaluate in Brinell, Rockwell and Vickers machines.

- Q: Or is it a coating that is applied? If so what types of steel? Or what types of coatings?

- No, usually they are just coated or galvanized. To make a steel that is truly more corrosion resistant raises it's cost quite markedly, where as coatings are pretty cheap. Almost all structural steel is just A36 mild steel (like 0.1% carbon, 0.05% Mn, and not much else). There are higher grades of structural steel, and bridges are made with truly more corrosion resistant carbon steels, but for a house it's just not the case.

- Q: Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- If you made up the right rigging you could probably suspend a Volkswagon with that, but certainly a refrigerator. It's flexible as steel goes - it's not rigid like tool steel, for instance. Since you ask about tempering and you are shopping at Home Depot, it should be just fine for a home project, if it looks like it will suit. Building a bridge or a machine tool, no.

- Q: How are steel coils used in the production of furniture components?

- Steel coils are commonly used in the production of furniture components due to their strength, durability, and versatility. These coils, which are made from high-quality steel, are first uncoiled and then fed into a machine called a stamping press. The stamping press uses a die to shape and cut the steel coil into various components required for furniture production, such as chair frames, table legs, or brackets. The use of steel coils allows for the mass production of furniture components with consistent dimensions and high precision. The strength of steel ensures that the components can withstand heavy loads and provide stability to the furniture. Additionally, steel coils can be easily formed into different shapes and sizes, enabling the production of a wide variety of furniture designs. Moreover, steel coils are often coated or treated with protective layers such as paints or galvanization to enhance their resistance to corrosion, moisture, and wear. This ensures that the furniture components have a longer lifespan and maintain their aesthetic appeal over time. In summary, steel coils play a crucial role in the production of furniture components by providing strength, durability, and versatility. They enable the mass production of precise and consistent components, and their protective coatings ensure the longevity and quality of the final furniture products.

Send your message to us

Z38 BMP Prepainted Rolled Steel Coil for Roofing Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords