WPC Decking Wood Plastic Composite Anti-water, Anti-insect, Recycled

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

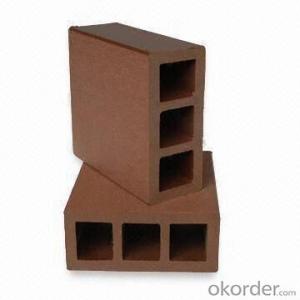

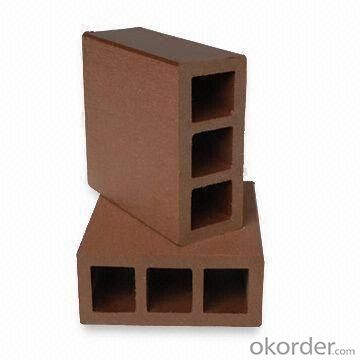

Structure of WPC Decking :

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

Description Main Features of the WPC Decking:

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

indoor wpc flooring

deck wpc solid

WPC Decking Images:

WPC Decking Specicication:

FAQ of WPC Decking :

1> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

2> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

3> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

4> How to buy and concerned terms?

*MOQ – 300m2 per item

*Lead time—2 weeks

*Departure port—Shanghai

*Package-- PE film, carton box or 2pcs.bundle, treated pallet

5> Certificates and Quality guarantee

*Certificates – CE&ISO 9001 complied

*Warranty—10 years

*Quality guarantee—test report for each order under the strict management system.

6> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

- Q: engineered flooring knowledge?

- Engineered flooring is often genuine wood. There is a top veneer of the money hardwood, laminated over several layers of plywood. There is no variation in dimension, and the product is very stable in terms of expansion and contraction. The ultimate advantage is the baked-on factory-finish which cannot be duplicated by on-site finishing. Some offer 50 year wear guarantees. For top quality hardwood floors, this is now the only way to go.

- Q: Such as title. Best to be detailed.

- At present, China's PVC flooring production is in a period of development, especially PVC sheet flooring (stone floor) production of domestic technology has been very mature, the country has a lot of well-known brands, production technology and quality are relatively high, many brands out Many foreign PVC floor manufacturers also set up factories in China, especially in South Korea, there are many manufacturers set up factories in China to produce. Some of the big brands of manufacturers will also own sheet flooring production line to China for production, and then sold back to the rest of the world. PVC flooring production technology alone is not yet mature, can only make a fake article, some key technology domestic floor manufacturers can only rely on imports, the product still has serious flaws, although there are foreign brands of manufacturers in China set up production , But the key technology is produced in foreign countries. If you want to introduce PVC flooring production line, I suggest you or the introduction of coil flooring production line as well. Because our country's PVC sheet flooring demand is very large, especially in the low-end PVC coil flooring market is very large. I am glad to answer the question of the landlord if any mistakes please forgive me

- Q: Yesterday forgot to turn off the water, so the two rooms of the composite floor Geng Gong blunt blossom yellow fake riveting all bubble in the water, and now the surface of the water has been disposed of, but there are water underground floor, the Internet Some people say that there is no big problem to dry, and some people say that the floor should be set off to dry the shop again, really do not know what kind of practice better, please help out, give suggestions? Thank you! More

- Puff board treatment is very troublesome. It is recommended that you all set off all dry and then paved again. Do not sun.

- Q: How to shop the natural wood flooring

- First keel, in the equipment, with the same solid wood

- Q: What are the advantages and disadvantages of solid wood flooring?

- Solid wood composite flooring advantages and disadvantages are the following: 1) solid wood flooring retains the solid wood flooring natural texture, foot feel comfortable features. 2) solid wood flooring and both strengthen the floor wear, easy to install, clean up the characteristics. 3) I solid wood flooring is very suitable for warm home decoration. 4) solid wood composite floor hardness than the floor is very small, very suitable for home with the elderly and children decorated family. 5) Solid wood flooring prices between the solid wood flooring and solid wood flooring of the method of prostitutes prostitutes 诓 magic ride between Wei and glass, belonging to the middle consumption of water balance, is the majority of the family can accept the scope of consumption. 6) solid wood flooring installation is simple, easy to clean up, no solid wood flooring so delicate. 7) solid wood flooring decoration effect is very good, many varieties, such as: solid wood composite antique floor, solid wood parquet flooring. Solid wood flooring is the lack of places: solid wood flooring is made of multi-layer floor, will contain a small amount of formaldehyde.

- Q: How to remove the composite floor stains

- How to remove the composite floor stains

- Q: How is the maintenance of the new floor laminate?

- Buy the floor on the Internet Bell, just paved, the new floor needs maintenance? More

- Q: Our home was originally installed in the composite floor, about 40 dollars that kind, has spent five years. Now the living room and a bedroom floor is not good, and some of the floor between the sewing a lot, and some of the floor muster deformation. I would like to put the living room and bedroom to fight, that is, the living room to remove the floor to the original floor of the bedroom was not bad. Is this ok? Shop out of the effect is not particularly bad, but also can not use 4, 5 years? More

- Yes, as long as the composite floor, whether it is reinforced composite or solid wood composite, are able to remove the other areas of the shop. How much time, smooth pull pull both the United States to help open the bubble or depends on how you maintain it, do not often use the wet mop mopping the floor [Bell floor, home dream starting point]

- Q: Solid wood composite flooring discoloration is what reason

- Long time the friction will wear off the paint.

- Q: My family for many years before the shop floor of the solid wood flooring taste of bamboo stalks mixed when the full river, and now some places have been blisters from the drums. Now someone in order to pursue foot feeling, want to shop in the solid wood flooring directly on the floor, consult experienced friends, so what is the problem? (My home in the north, 9th floor) Also, if the demolition of solid wood flooring, re-leveling the ground, with a good cement or a big board? Thank you so! Question added: if the solid wood over the shop, how much higher than now? My house is only 2 meters high. More

- You like this is the best way to get rid of the original solid wood flooring and then pave the way to taste the white straw when the fiber is mixed with full. There are two reasons: 1. Solid wood flooring with the time for a long time prone to sound, keel between the gap which is easy to filth, and if the original solid wood flooring is not smooth in the above and then the floor composite flooring easy to ups and downs, loose. 2. Your current room is only 2.6 meters high, remove the solid wood flooring and then shop composite floor to clear the ground leveling, to save about 3-5 cm of space. The ground to re-leveling or cement with good, or self-leveling can also be.

Send your message to us

WPC Decking Wood Plastic Composite Anti-water, Anti-insect, Recycled

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords