Woven or Non Woven Geotextile Backed Best Price High-Density Polyethylene Geomembrane as Waterproof Facing of Earth and Rockfill Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2. HDPE geomenbrane Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

3. HDPE Geomembrane Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

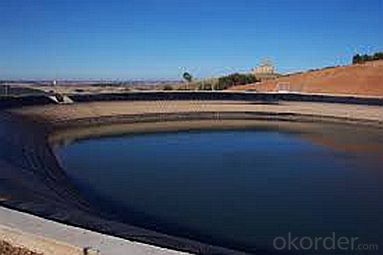

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope prtection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different geotextile testing methods?

- There are several different geotextile testing methods, including but not limited to, grab tensile strength testing, puncture resistance testing, tear resistance testing, burst strength testing, and permeability testing. These methods help assess the physical properties and performance of geotextiles in various applications.

- Q: Is there a geotextile for reed cultivation?

- Big slope pond words use better, need depth laying, with geomembrane

- Q: Geotechnical construction of the weather when there is any requirement

- Hello, geotextile construction is very simple, laying with less cutting, less overlap for the principle. Take the head set aside about 25 cm. Using double take the head, sew two lines. This is in principle to ask this, the general construction can not do so carefully. Huazhi geotechnical materials manufacturers to answer, need to talk.

- Q: Geotextile packaging what are the requirements

- Geotextile packaging requirements are as follows: 1, staple acupuncture non-woven geotextile according to set into a long volume of packaging. The fixed length shall be determined in accordance with the product specification or the parties concerned. 2, the product of the splicing rate should be less than 15%, the total length of each piece of stitching products should be 7.1.1 fixed length plus 1m or more, every 100m to allow splicing 2, or by the supply and demand sides to determine. 3, the length of the product in the 30m below a small package can be a separate package, for a head treatment, 4, product packaging should ensure that no scattered, no damage, no pollution. Users have special requirements, the supply and demand sides to determine the consultation.

- Q: How do geotextiles help with soil reinforcement in embankments?

- Geotextiles help with soil reinforcement in embankments by providing a stable and strong layer between the soil and the embankment structure. They act as a barrier, distributing the load evenly and preventing soil erosion and movement. Additionally, geotextiles enhance the overall stability and durability of the embankment by improving drainage and reducing the potential for soil settlement.

- Q: Why do you want to wrap the geotextile

- Geotextile has a certain degree of waterproof isolation

- Q: How do geotextiles help with load distribution in pavement systems?

- Geotextiles help with load distribution in pavement systems by providing a flexible and stable foundation. They act as a reinforcement layer, spreading the load from traffic evenly across the pavement surface. This helps to prevent the formation of stress points and reduces the risk of pavement failure. Geotextiles also help to reduce the amount of rutting and cracking in the pavement, leading to increased durability and longevity of the road.

- Q: Consult geotextile and geomembrane is not the same thing?

- Geomembrane completely soiled geotextile is to keep the wet state of water will evaporate

- Q: What are the advantages of using geotextiles in green space development?

- There are several advantages of using geotextiles in green space development. Firstly, geotextiles help in soil stabilization by preventing erosion, which is crucial for the long-term sustainability of green spaces. Secondly, they improve water drainage and filtration, allowing for better moisture retention and reducing the risk of waterlogging. Additionally, geotextiles act as a barrier to weed growth, reducing the need for herbicides and manual maintenance. Lastly, they provide reinforcement and support to the soil, increasing its load-bearing capacity and enabling the development of structures like pathways and driveways. Overall, the use of geotextiles in green space development enhances the durability, functionality, and aesthetic appeal of these areas.

- Q: What are the environmental impacts of using geotextiles?

- The environmental impacts of using geotextiles can vary depending on the specific application and the materials used. However, in general, geotextiles can have positive environmental benefits. They can help prevent soil erosion, promote vegetation growth, and provide stability to slopes and embankments. Geotextiles can also facilitate the filtration of water and the retention of sediment, reducing water pollution. Additionally, the use of geotextiles can minimize the need for heavy construction machinery, which can help reduce carbon emissions and minimize disturbance to natural habitats. However, it is important to consider the potential environmental impacts associated with the manufacturing, disposal, and maintenance of geotextiles, as these can contribute to greenhouse gas emissions and waste generation if not managed properly.

Send your message to us

Woven or Non Woven Geotextile Backed Best Price High-Density Polyethylene Geomembrane as Waterproof Facing of Earth and Rockfill Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords