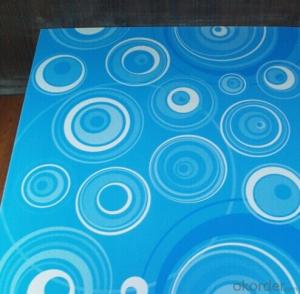

High Quality PVC Ceiling Panel Philippines with Nice Designs

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

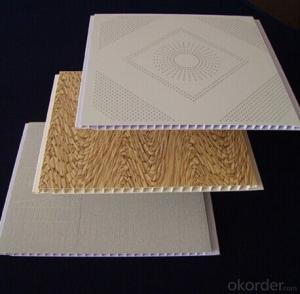

Wooden PVC Panel High quality Nice Designs

We have specialized in PVC panel for many years. And 80% output of our PVC panel is export to oversea market.

Usual Specification:

Length:5.98m,5.95m,5m or customized

Width:30cm,25cm,20cm, 19.5 cm, 19 cm, 12 cm or customized

Thickness:1.2cm, 1.1cm, 1.0cm, 0.9cm,0.85cm,0.8cm,075cm,0.70cm,0.6cm,0.5cm or customized

Color: According to the customers’ requirements

Pattern: Modern design

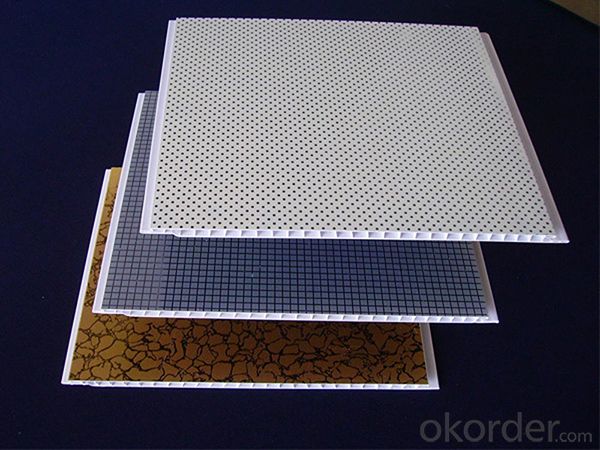

Surface: common glossy, high glossy, printing, transfer printing(hot staming), laminated printing

The feature:

1)The variety of colors and patterns

2)High intensity, resist erosion, anti aging

3)Fireproof, waterproof, environment friendly

4)Waterproof and heatproof

Applications:

Household Ornament: Wall and ceiling of indent independent house bathroom

Public and Management Place: Toilet of building and hall, bathroom and kitchen

Usual Packing: 10pcs/shrink wrapping or carton

Main market: South America, Eastern Europe, Southeast Asia, Eastern Asia, Africa, Oceania and Mid East.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q: Why do some people tell me when there is a lot of scratches on the color of the polished surface.

- PVC board after polishing the appearance of a color does not appear on the scratches, which is mainly because PVC its material surface is smooth, but the hardness and wear resistance and not, it is easy to scratch or grind scratches, but you It will be polished for polishing.

- Q: My home PVC board is always issued a flap sound, how is it? (My family is not the top floor)

- The ceiling of the plate that may be caused by the deformation of the keel need to open to see the corporal is not a keel deformation go

- Q: Will the PVC transparent board with what glue can put two together?

- PVC glue on the line

- Q: PVC sheet is not wood-based panel

- Is the man-made plate. PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board. PVC is generally used for flooring, ceilings and leather surface, but because soft PVC contains softener, easy to become brittle, easy to save, so its use has been limited. Hard PVC does not contain softener, good flexibility, easy to shape, not brittle, non-toxic and pollution-free, long storage time, so it has great development and application value. PVC foam board with anti-corrosion, moisture, no water, can not drill, can be sawing, can plan, easy to thermoforming, hot bending and other characteristics, it is widely used in furniture, cabinets, Yugui, Box core, indoor and outdoor decoration, building materials, chemical and other fields with the board, advertising signs, printing, silk screen, inkjet, computer lettering, electronic instrumentation products packaging and other industries. PVC hard plastic plate with excellent corrosion resistance, insulation, and a certain degree of mechanical strength; after the secondary processing can be made of sulfuric acid (hydrochloric acid) tank (barrel); medicine with empty needle frame, Toilet water tank; processing products of the template, decorative panels, exhaust pipes, equipment, and other special-shaped products, containers. It is an ideal choice for chemical, building materials, decoration and other industries.

- Q: PVC plastic plate dirty how can quickly wipe clean?

- Wash with toothpaste with a toothbrush Because it is not a big thing, you can simply use a toothbrush stained with a little toothpaste and then gently wipe it again until you can clean up. This can also add flavor to the bag.

- Q: We had a plumber come to unclog our drain on our tub. He never looked at the pipes that we had or anything. He just walked in started up his electric snake and immediately busted our pipe causing at least $10,000 worth of damage to our living room ceiling and floor.He is now trying to say that it wasn't his fault because we had the wrong kind of pipe and it was brittle.After talking to some general contractors, my thinking is that he used the wrong tool for the job and did not use reasonable skill and care. Of course the pipe looks brittle after your machine busted it!I fear we have a battle ahead. Looking for some good information.

- Generally speaking yes it is ok to do this but some sort of survey should have taken place prior to its use. This should establish the condition of the pipework as older pvc pipes will degrade in sunlight particularly and go brittle.Obviously I am unable to comment on the wrong type of pipe as I dont know what pipe this is but I think its age is more likely to be the main problem not its type.

- Q: Will pvc floor is how to make out, it is best to specific? Thank you!

- More is the wood-plastic foam board is nothing more than resin powder, wood powder, hard calcium, stabilizer and other small material mixed extrusion

- Q: Curve saw can not saw 15mm pvc board? Will it be melted?

- Gray handle Curved saw blade is particularly suitable for cork, three plywood and fiberboard cutting, can also be applied to hardwood and plywood.

- Q: Is pvc board insulator?

- Seemingly no absolute insulator!

- Q: PVC board bathroom cabinet how to determine the quality of the plate, PVC board which is the advantage of who said

- At present the market on the bathroom cabinet, the price difference on the thousand dollars, the quality is naturally good and bad. In the purchase of bathroom counters, you need to look at the manufacturers to provide products such as certificate of competency and other materials. Of course, the most secure way, of course, is to try to buy those well-known brand manufacturers of products, not only quality assurance, post-service will make you worry a lot.

Send your message to us

High Quality PVC Ceiling Panel Philippines with Nice Designs

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords