Best PVC Ceiling Panels for Decoration

- Loading Port:

- Shanghai, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X40HQ m²

- Supply Capability:

- 8000 M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Materials: PVC Resin, Calcium Carbonate

Size: 595×595×8mm

Weight: 3.2kgs/m2…

PVC content: 45%, 50%, 55%...

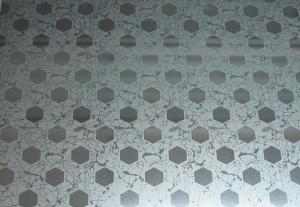

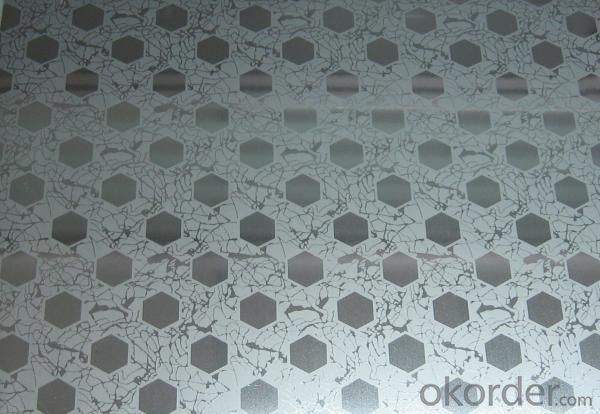

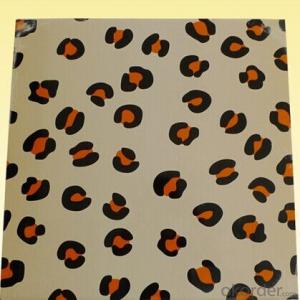

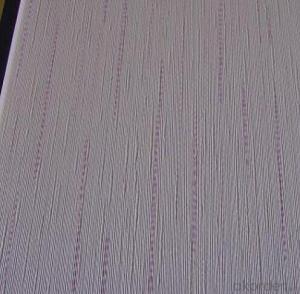

Textures: Printed, Foiled

Processing performace of PVC Ceiling Tiles:

Can be processed by drilling, sawing, nailing, planning and bonding and be in hot-forming, hot-bending and hot-folding and be welded and bonded with supplementary materials.

Main Characteristic of PVC Ceiling Tiles:

Water proof and suitable for both wet and dry areas

Interlocking system, DIY supported

Simple and efficient to install and clean

Long life time

Healthy and environmentally friendly

Variety of colors and patterns for decoration

Application Areas of PVC Ceiling Tiles:

Bathrooms, Kitchens, Factories, Workshops, Warehouses...

- Q: Production of PVC foam board of raw materials are what ah? What is the role of ah?

- Production of PVC foam board main raw materials are: PVC resin, stabilizer, foam regulator, foaming agent. Pigments. Fillers,

- Q: Transparent PVC board how much money a square

- Sun room can be used pc-resistant board or pc sunshine board. Better results. PC sun panels: sun panels are widely used in public, civil construction lighting ceiling, highway noise, modern flower room lighting materials, and the other for the floor materials, bathroom doors, etc., with good impact resistance, noise, lighting, , Flame retardant and other advantages. Is the light weight and high strength of the perfect coordination, and the material itself was transparent as clear water. It is widely used in stadiums, public buildings, industrial buildings, civil buildings, modern greenhouses and interior display, etc., and for these occasions to provide high-quality low maintenance costs lighting solutions. Transparent plate transparency of up to 80%. PC Nai Liban: the United States GE, Germany Bayer, the Japanese Teijin new pc particles as the main raw material, the introduction of Germany, Japan today developed from advanced technology. PC general-purpose durability plate has a co-extruded UV layer of the endurance plate and double-sided UV withstand board, noise, cold, excellent heat resistance, cold bending ability and thermal molding ability, all-round blocking ultraviolet rays, with strong anti-aging properties.

- Q: Pvc soft glass poisonous?

- Generally not toxic, different manufacturers of different materials.

- Q: Pvc board afraid not afraid of water?

- And some because of the problem inside the raw materials will be absorbent, transparent and some will be white But basically no effect on performance

- Q: Pvc board on the human body is not harmful

- Pvc board is not harmful to the human body. PVC is non-toxic harmless, only in the extreme temperature or combustion will produce harmful gases or substances PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: How to judge the true and false PVC board?

- True and false PVC to determine: you can take a small amount of PVC board with a flame burning, if a large number of black smoke, and accompanied by pungent smell of hydrogen chloride, the flame after the burning surface was black charcoal, the basic can be concluded that PVC; Not associated with a lot of black smoke, no irritating smell, and the flame after the burning surface was white or light white, it may be polyethylene or polypropylene plate.

- Q: Will pvc floor is how to make out, it is best to specific? Thank you!

- There are many, soft heart. Soft multi-layer lamination. Hard wood plastic, foam and so on

- Q: What is the PVC board and KT board, what are the specific role?

- PVC is a plastic material, and KT board is a foam material, two kinds of materials are not the same, but all in the billboard outdoor advertising with more. PVC than the KT board expensive

- Q: PVC board and EVA board What is the difference, which is good flexibility

- EVA has good flexibility

- Q: PC board PV board PVC board PPV board distinction and use

- Pvc board generally used with the bathroom and kitchen, the other two I am not very clear. But home improvement using PVC board more.

1. Manufacturer Overview

| Location | Haining,China |

| Year Established | 1998 |

| Annual Output Value | US$1.5 Million - US$2 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000 certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 18800 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered;Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Best PVC Ceiling Panels for Decoration

- Loading Port:

- Shanghai, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X40HQ m²

- Supply Capability:

- 8000 M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords