Newly Designed PVC Ceiling Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

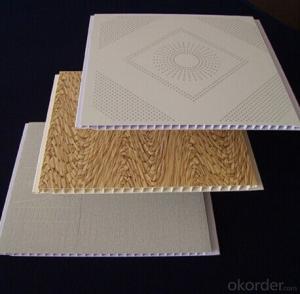

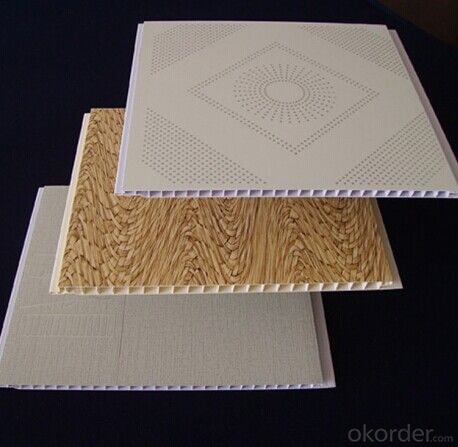

Newly designed PVC Ceiling Panels:

1.ISO9001,Soncap,CE&SGS

2. Easy-clean surface & maintenance free

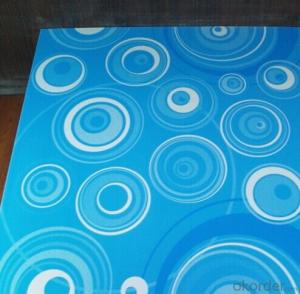

3.Various designs & spec

Newly designed PVC Ceiling Panels

Company Information

We are a professional PVC Ceiling panels manufacture since 1992, offering hundreds of patterns and colors of PVC panel and monthly output up to 480,000 Sqm.

Product Advantages:

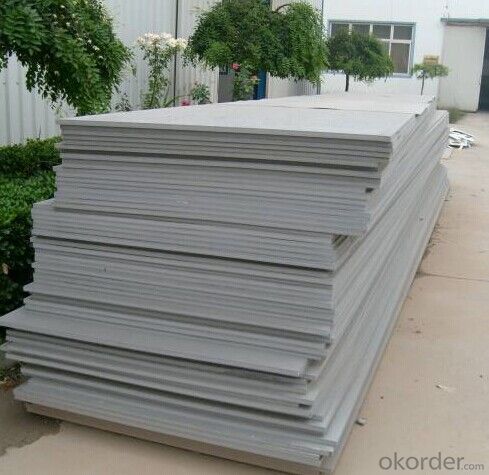

Normal Packing: 10 pcs per PE Film Package with carton End cap at both end of the package.

Special Packing: 1. transparent film between two panels to protect the surface; 2. carton box with 10 pcs or 20 pcs per carton; 3. as requested. Special Packing fees extra.

Shipping: 7-10 days upon receipt of deposit for a 20GP and 10-15days for a 40'HQ.

.

Product Description

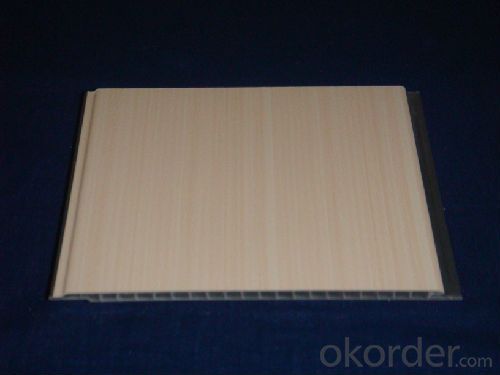

20cm*7.5mm groove PVC ceiling panels, for Africa Countries, India, Mid-east and Europen markets,with CE, ISO9001:2008, SONCAP,SGS certification

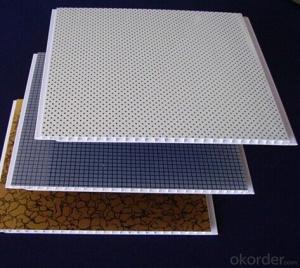

Different types of PVC ceiling we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

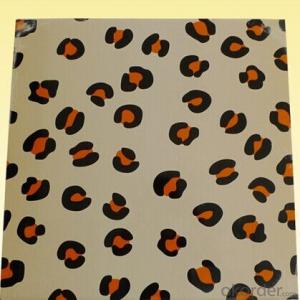

4, Transfer Printing PVC Panel

The hottest specifications of PVC ceiling on the market:

Thickness: 4mm/4.5mm/6mm/7.5mm/9mm/10mm/11mm/12mm

Length: 3m-5.95m

Width: 200mm, 250mm, 300mm, 600mm

PVC percentage: 35%-75%

Any other specifications are also available here.

Main Product Features:

| Newly Designed PVC Ceiling Panels | ||||||||

Lucky PVC | Width | Thickness | N.W. | Packing | Loading in 20’GP (5.8m length) | Loading in 40'HQ (5.95m length) | ||

| mm | mm | Kg/Sqm |

| packages | amount/Sqm | packages | amount/Sqm |

Flat Panel | 100 | 7.5 | 2.2 | 10 pcs/PE film package | 736 | 4268.8 | 1610 | 9579.5 |

| 150 | 7.5 | 2.3 |

| 496 | 4315.2 | 1084 | 9674.7 |

| 200 | 6 | 1.8 |

| 462 | 5359 | 910 | 1829 |

|

| 10 | 3.8 |

| 276 | 3201.6 | 598 | 7116.2 |

| 240 | 9 | 2.7 |

| 254 | 3535.7 | 566 | 8082.5 |

| 250 | 4 | 1.5 |

| 558 | 8091 | 1070 | 15916 |

|

| 4.5 | 1.65 |

| 495 | 7177.5 | 941 | 13997 |

|

| 6.5 | 2.1 |

| 333 | 4828.5 | 758 | 11275 |

|

| 7 | 2.2 |

| 315 | 4567.5 | 704 | 10472 |

|

| 7.5 | 2.3 |

| 297 | 4306.5 | 600 | 8925 |

|

| 8 | 1.6 |

| 279 | 4045.5 | 614 | 9133 |

|

| 11 | 3.4 |

| 189 | 2740.5 | 432 | 6426 |

| 300 | 9 | 2.3 |

| 198 | 3445.2 | 429 | 7658 |

Groove Panel | 200 | 6 | 1.8 |

| 462 | 5359 | 910 | 10829 |

|

| 7.5 | 2.2 |

| 364 | 4222.4 | 785 | 9341.5 |

| 250 | 8 | 2.7 |

| 279 | 4045.5 | 590 | 8776 |

| 300 | 9 | 3 |

| 176 | 3062.4 | 418 | 7461.3 |

Wave Panel | 250 | 8(four) | 3.2 |

| 238 | 3451 | 564 | 8389.5 |

| 250 | 8(three) | 3.7 |

| 238 | 3451 | 564 | 8389.5 |

Suspended Ceiling | 595 | 7 | 2.1 | 20pcs/carton | 468 | 3313.7 | 1197 | 8475 |

| 605 | 7 | 2.2 |

| 450 | 3294.2 | 1160 | 8213 |

Product Specifications:

Application of pvc ceiling

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

1, Household Ornament: Wall and ceiling of indent independent house bathroom

2, Public and Management Place: Toilet of building and hall

3, Common Office: Ceiling of business Place

Feature of pvc ceiling:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

4) Interior decoration for ceiling. Easy clearing, healthy and environmental.

Images:

- Q: What is the difference between steel and PVC gussets?

- Steel, PVC, aluminum plate is three different materials, steel and steel doors and windows is almost, PVC is the lowest level of anti-aging plastic, aluminum plate is relatively thin aluminum plate anti-aging degree is the best. Price and quality level is proportional to, PVC two, thirty-one square, about 40 square meters of steel and aluminum buckle in a hundred or so a square.

- Q: Hibiscus board and PVC board commonly used and do what?

- Product characteristics Anti-aging, anti-ultraviolet radiation; oil, acid, alkali and other organic chemical composition corrosion; sound-absorbing, noise, thermal insulation; light texture, easy to store, anti-aging, anti-aging, anti-aging Transport, processing, cutting, carving and so on

- Q: Before the home decoration Pvc board, now want to get rid of, directly stickers can be wallpaper, or other methods? Do not remove Pvc board paste what can

- PVC board above certainly can not paste the wallpaper, one paste will not be long; Second, PVC will generally have seams! It is certainly unreasonable to paste the wallpaper on such a wall. Do not know your home PVC board is what kind of? If all the indoor use of PVC board is not environmentally friendly ah!

- Q: Pvc board ceiling how much manual

- Look at how big your squares are ordinary people and you will not be square

- Q: Is the heat resistance of the PVC board?

- Do not know where to use it is no problem, the high temperature certainly not work, and long-term high temperature also have an impact on performance.

- Q: Pvc stone floor with hot water bubbles after the UV layer can be torn from the floor, and then you can smell the irritating smell, the business that no formaldehyde, but I think this taste UV layer is certainly sticking up and not hot The

- No. Pvc floor from the structure of the main multi-layer composite and homogeneous through-heart and semi-homogeneous body type 3. The so-called multi-layer composite PVC floor is that it is a multi-layer structure, generally from 4 to 5 layers of laminated structure, generally wear-resistant layer (including UV treatment), printing film, glass fiber layer, Foam layer, grass-roots level. UV treatment is the use of epoxy resin for surface reinforcement in a way that can play anti-pollution and effective absorption of ultraviolet light, enhance wear resistance, delay product aging and easy to clean the role.

- Q: My daughter inside the floor of the house is a little green light green point of the PVC board, would like to ask what color with a warm wall

- Light pink

- Q: Installation works PVC wire tube castable board inside the plugging dredge there to sell?

- In the construction process, there are often pre-arranged lines PVC pipe is blocked by concrete and can not successfully threading the situation , In the process of dredging, often can not accurately find the location of the clogging and waste of human, material, financial, time, and even delay the duration. This is the most troublesome thing to install the construction workers!

- Q: Pvc plate density (g / qm): 1,4 - 1,5. The Which unit (g / qm) qm is what does that mean?

- International density units are generally in kilograms per cubic meter (kg / m?), in addition to grams per square meter (g / cm?).

- Q: PVC sheet with formaldehyde?

- In fact, PVC flooring is green, and its cost-effective, So more and more people need it. But some people will ask the PVC floor to The end contains no formaldehyde? Actually it is made of polyvinyl chloride material The floor. Specifically, it is based on polyvinyl chloride and its copolymer resin To the raw materials, adding fillers, plasticizers, stabilizers, colorants and other accessories, On a sheet-like continuous substrate, by a coating process or by calendering, extrusion or extrusion processes. ??? PVC floor is containing formaldehyde in fact for the formal is not containing formaldehyde, But there are some fake and shoddy products, there is no guarantee that does not contain, but for positive Regulation of PVC is not toxic, it has also been widely used in doors and windows manufacturing or Such as drainage. So when we buy the time to the regular PVC Floor buying and selling center to buy. This on your personal health and safety play a role Oh. We have to be careful Oh

Send your message to us

Newly Designed PVC Ceiling Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords