Cheap PVC Ceiling Panels - Wooden Design by CNBM Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

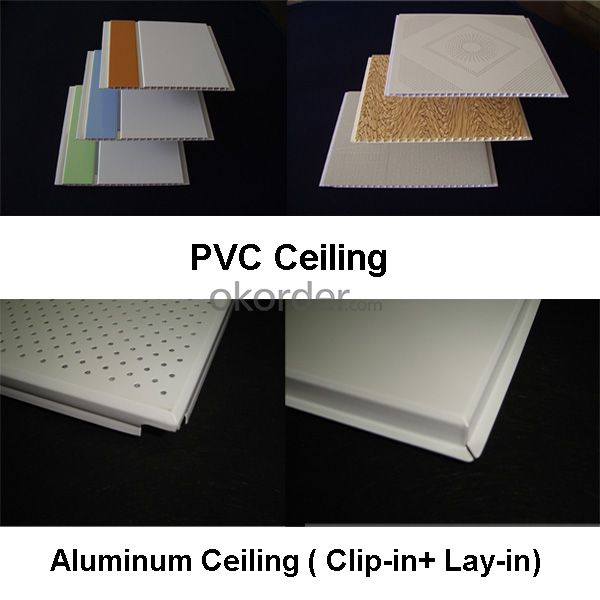

Wooden design pvc ceiling panels CNBM supply

Specification:

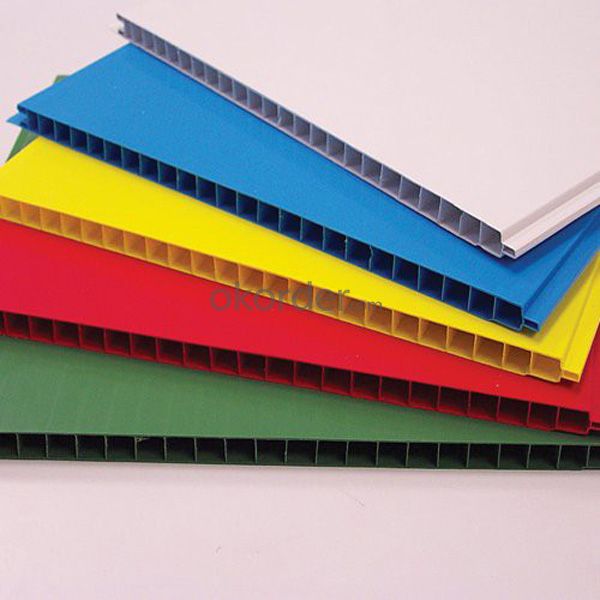

1.Width: 0.915,1,1.22,1.56,2.05m

2.Thickness: 1~40mm

3.Colors: as your requirementThickness: 1mm~25mm

PVC Sheet-applied treatments:

Materials processing: Cut; Drilling; Milling; nail etc.

Heat application: wisting, bending; Resource work; Heat styling

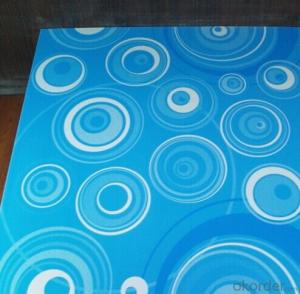

Other: Digital Printing; Application of alternative soil; Application sheets; Painting

Good features:

1. Light weight,good tenacity, high rigidity

2. Fireproof and flame retardant

3. Good insulation

4. No sopping, no deformation

5. Easily to processed

6. Good plasticity, being an excellent thermoform material

7. Sub-light surface and elegant vision

8. Anti-chemical corrosion

9. Suitable to silk screen printing

10. With imported dyes, unfading and anti-aging

Applications:

Advertising: signs, exhibition stands, routing sheets, etc..

Industry: Manufacturing industries, control cabinets, etc., and warning signs.

Construction: Wall cladding, sandwich panels, interior decoration etc.

Wooden design pvc ceiling panels CNBM supply

Produce Arrange:

PVC foam sheet | |||||

Specifications | Thickness(mm) | Densityg/cm3) | MOQ(pc) | Color | Application |

0.915*1.83 | 1--10 | 0.5-0.8 | 1000 | White | Sign board |

1.22*2.44 | 1--10 | 0.5-0.8 | 500 | White/Colored | |

1.56*3.05 | 1--10 | 0.5-0.8 | 500 | White/Colored | |

2.05*3.05 | 1--10 | 0.6-0.9 | 500 | White/Colored | |

PVC Celuca Sheet | |||||

Specifications | Thicknessmm | Densityg/cm3) | MOQ(pc) | Color | Application |

1.22*2.44 | 4--40 | 0.5-0.8 | 500 | White | Furniture |

1.56*3.05 | 8--40 | 0.6-0.8 | 500 | White | Furniture |

PVC rigid sheet | |||||

1.22*2.44 | 1--3 | 1.42 | 500 | Sign board |

Packaging: Packed in Carton, Carton in Container

Shipping: All the shipping ways can be chosed as below:

Related Products

Wooden design pvc ceiling panels CNBM supply

- Q: PVC plastic plate is environmentally friendly

- PVC plastic plate processing need to join the stabilizer and other additives, if the stabilizer in lead, barium, chromium and other heavy metals exceeded, it is considered not environmentally friendly, but now the domestic heavy metal detection is not very strict

- Q: What is the difference between oak bathroom cabinet and PVC bathroom cabinet?

- Oak has a solid wood texture, the use of waterproof and environmentally friendly paint spray treatment, compared to other man-made sheet, lower formaldehyde emission, natural environmental protection, but also more durable. Advantages: health and environmental protection, natural honest, high-grade elegant. Disadvantages: expensive. The PVC is a plastic bathroom cabinet, mainly to PVC as a plastic panel, after vacuum pressure adsorption in the MDF or moisture board, moisture board for wood pulp with moisture-proof particles of curing products, generally blue or green, Blister can be drawn after the board as a whole, without edge, with excellent moisture-proof waterproof performance. Advantages: rich colors, high temperature, anti-carved, easy to clean up. Disadvantages: resistance to chemical corrosion is not high. ???? Oak has red oak and white oak, usually Mito imported. There is a domestic called oak, and oak with the Branch, similar texture

- Q: PVC board how rub rub

- PVC style, rich colors. Giving a stylish, crisp feeling. Suitable for young married couples to use.

- Q: Pvc board ceiling each piece of zero sale!

- Should be called plastic buckle plate, cheap more than twenty square, good sixty-seven square square

- Q: My house would like to buy PVC decorative board ceiling but do not know how to buy PVC board how to determine the purchase of PVC board is toxic to ask you prawn support a few strokes Thank you

- PVC easy We produce PVC high-end green pellets for three decades, the landlord said the PVC decorative plate is difficult to judge the naked eye alone. Because this sheet is non-transparent products. At present, most of the buckle boards on the market are lead salts as stabilizers, and lead salts are known for many years ago as non-environmentally friendly raw materials. But there are also a lot of buckle manufacturers use environmentally friendly calcium zinc or organic tin to do heat stabilizer, this kind of relatively environmentally friendly non-toxic. If you really want to use more intuitive way to judge, then the price of some of the total will always be more assured. Because the better the use of raw materials, the higher the cost.to crack, fade, prone to scratches, the price is cheaper

- Q: How to buy pvc floor?

- Pvc floor is made of PVC as raw material, this material is non-toxic, no formaldehyde, so there will be no smell, with realistic imitation wood, carpet pattern, stone pattern and other patterns. We can from the sense of smell, touch, vision, hearing simple to determine whether the floor is qualified One: by the sense of smell. In the selection of the floor, with the nose smell, the floor if there is irritating smell distributed, the floor is likely to contain formaldehyde, or formaldehyde content exceeded. Formaldehyde can damage the body's body and have a long release period. Two: by touch. Hand to feel the flexibility of the floor, or feet to feel the floor of the comfort and smoothness. Floor trampling uncomfortable, not smooth, non-slip, are inferior PVC plastic floor. Three: by vision. Floor color is not pure, pattern, pattern is not clear, irregular, the surrounding floor or surface damage and scratches and so can determine the poor quality of the floor. Four: by hearing. Good PVC plastic flooring has a good sound insulation, customers in the selection of the floor when you can try to move around to determine the PVC plastic floor sound insulation effect, sound insulation is poor, are inferior flooring.

- Q: What is PVC material?

- Polyvinyl chloride. Basic features: It is one of the world's largest production of plastic products, cheap, widely used, polyvinyl chloride resin is white or light yellow powder. Depending on the application, different additives may be added, and the polyvinyl chloride plastic may exhibit different physical and mechanical properties. In the polyvinyl chloride resin by adding the right amount of plasticizer, can be made of a variety of hard, soft and transparent products. Pure polyvinyl chloride density of 1.4g / cm3, adding plasticizers and fillers such as the density of PVC plastic parts is generally 1.15-2.00g / cm3. Hard polyvinyl chloride has a better resistance to tensile, bending, compression and impact resistance, can be used alone as a structural material. Soft polyvinyl chloride softness, elongation at break, cold resistance will increase, but the brittleness, hardness, tensile strength will be reduced. Polyvinyl chloride has a better electrical insulation properties, can be used for low-frequency insulation material, its chemical stability is also good. As the thermal stability of polyvinyl chloride is poor, long-term heating will lead to decomposition, release HCL gas, so that PVC discoloration, so its narrow range of applications, the use of temperature is generally between -15 ~ 55 degrees. The main purpose: Because of the high chemical stability, it can be used to make anti-corrosion pipes, pipe fittings, oil pipelines, centrifugal pumps and blowers. Polyvinyl chloride board is widely used in the chemical industry to produce a variety of storage tank lining, building corrugated board, doors and windows structure, wall ornaments and other building materials. Because of electrical insulation performance, in the electrical, electronics industry, for the manufacture of plugs, sockets, switches and cables. In daily life, PVC used in the manufacture of sandals, raincoats, toys and artificial leather, etc.!

- Q: I plant processing acrylic board PVC foam board KT board sun board PVC board acrylic board Hibiscus board foam board plastic plate aluminum plastic plate transparent board density board

- Not processing PC board ah, we process PC board, you can exchange

- Q: its in a place i cannot get to without knocking down a wall and ceiling - is there anything i can pour down the drain to stop the leak at the joint - its a very small drip

- Is this a joint inside the wall? If It is, is there any way you can measure down the wall and cut a small hole and see the joint? I have fixed pvc using a soldering iron even with pressure in the pipe. I wish I could see it.

- Q: Pvc ceiling can do several shapes

- PVC ceiling panels are now being gradually eliminated, most of them are with aluminum buckle plate, compared to PVC, aluminum plate more environmentally friendly health

Send your message to us

Cheap PVC Ceiling Panels - Wooden Design by CNBM Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords