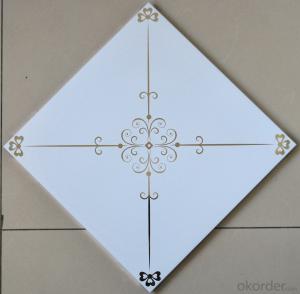

Wood Grain Color Coated Ceiling Aluminium Panels for Home-Decorating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

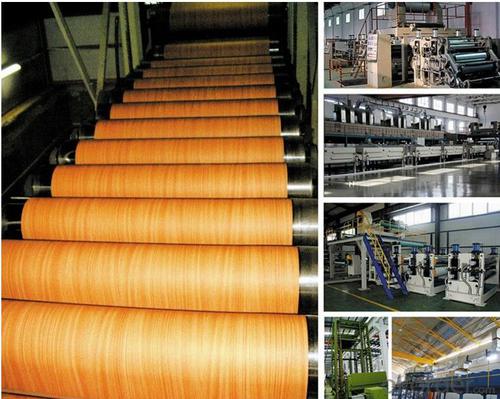

Wood Grain Color Coated Aluminum Sheet Used For Home-Decorating

Production description

01)Material: aluminum alloy A1100, A3003, A3005, A3105,A8011

02)Aluminum thickness:0.04-1.20mm

03)Max coil width: 1600mm(standard 1240mm)

04)Coil's standard diameter:1200mm, Interior diameter: 405mm,505mm, etc.

05) weight: 0.5-4.0T/coil or by buyer's option

06) Coating: PE or PVDF coating

07) Surface treatment: anti-scratch, high glossy, matt

08) Color: wooden grain, marble stone, plain color,3D, HD, metallic, patterned, etc.

10) Coating thickness: double coating-25 micron, single coating-18 micron, primer-5 micron

11) Coating hardness: (pencil hardness) HB

12) Coating adhesive: no lower than first grade

13) Impact resistance: no cracking and peeling(50kg/cm, ASTMD-2794:1993)

14)Flexibility(T-bend):2T or by your option

15) MEK resistance: more than 100

Packaing and Delivery

Packaging details | Standard seaworthy exporting carton, Wooden pallets,waterproof paper and plastic kraft coverage or or as per customer's requirements |

Delivery details | 25-30 days after getting your down payment |

FAQ

--Q: How can I request a product sample?

A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

--Q: How can I request a product catalog?

A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

--Q: Wha's your payment terms?

A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

--Q: What's your trade terms?

A: FOB, CNF(CFR), CIF, EXW.

--Q: How long is the quality guarantee?

A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

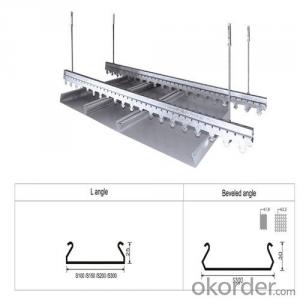

- Q: Want to do aluminum ceiling production, do not know what sets of production equipment. What is the price of the equipment?

- What you mean is that you do not understand anything. Which is a P, when the people give you dead do not know!

- Q: What is the size of the integrated ceiling plate?

- Home improvement, there are two places to consider the installation of aluminum buckle ceiling, one bathroom, one kitchen, then, the choice of aluminum buckle ceiling will take into account.

- Q: How to open the aluminum plate hanging ceiling?

- With a wallpaper knife or key inserted into the gap, forced down a pull, hand a take it.

- Q: Recently home house in the decoration, to see a lot of integrated ceiling model. Now very depressed is the integrated ceiling and aluminum buckle plate integrated ceiling in the end what is the difference? Is it the same thing? Very depressed ~

- Identify the method of integrating the ceiling: A: Look: the inferior buckle surface looks rugged, and there will be particles. The quality board looks very flat and the panel is softer. B, smell: the lighter with a lighter plate of the corner, 30 seconds will be charred, and the smell of plastic scorched scorch, roller anti-oil even if the burning of the sun will not have a pungent odor. C, touch: the temperature of the film board is the plastic temperature, so relatively high, to warm a little, roll the temperature of the board is the temperature of the metal, to cool a little. D, listen: hand cover the corner of the panel, gently knock on the center of the panel, the film board sound boring a little, rolling the sound of the board crisp. E, scraping: the difference between the roller and the board is good or bad, poor roller coating in the bending out there will be a slight burst, hand scraping scraping the surface layer will be scraped, a good buckle will not.

- Q: What are the benefits of using a flat aluminum plate with aluminum ceiling ceiling?

- The disadvantage is that the visual effect of flat aluminum is not very good. I hope my solution will help you

- Q: Aluminum buckle plate can be installed into a ceiling of Yuba it

- A 30cm * 30cm aluminum plate, 1.2mm thick, good quality of our price of a 5.5 yuan or so. Plus accessories (I use the Oplone, good quality) a flat about 90 blocks

- Q: How to choose aluminum cords plate ceiling color

- In accordance with their own needs to choose the style of the ceiling, you can also choose some of the suppliers to do the product comparison

- Q: What kind of light is the kitchen? Can the old ceiling lamp be installed?

- Because the aluminum plate is directly buckle in the keel of the gap, if too heavy, then a long time by gravity, and so on to fall off. But as many will be out, this has not done the experiment, not clear, but according to the general buckle buckle degree, the kind of no more than 500g of the ceiling should be no problem.

- Q: Can I install aluminum buckle plate and then install gas water heater?

- Can be installed in the aluminum plate after the installation of water heaters, smoke pipe can be directly out from the window.

- Q: Lycra board ceiling price 60 square about how much money you need

- Aluminum buckle board Features: One, colorful, durable, do not fade Second, environmental protection, fire, moisture Third, diversified varieties, patterns, colors can be customized according to user requirements Fourth, the art of small ceilings personalized Five, with a high strength and excellent flexibility

Send your message to us

Wood Grain Color Coated Ceiling Aluminium Panels for Home-Decorating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords