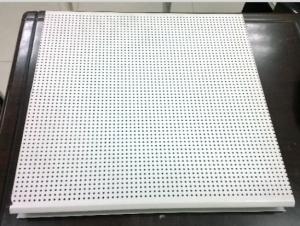

Aluminium Strip Ceiling Malaysia C-Strip Aluminum Ceiling Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Designed and engineered to perform in multiple commercial environments under multiple stresses,Metal Ceiling systems allow cutting-edge technologies to be applied to the most modern or traditional designs. Every component is designed and fabricated to exacting specifications and the highest manufacturing standards.

Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

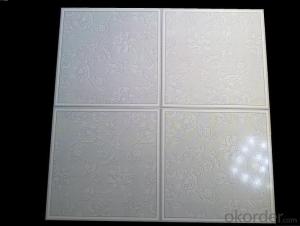

Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

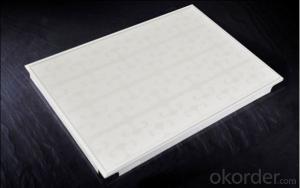

Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

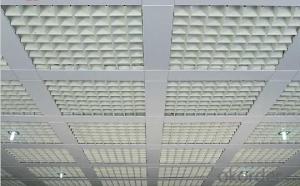

Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

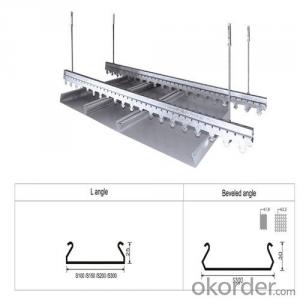

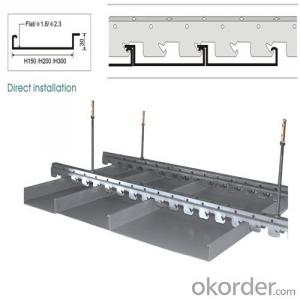

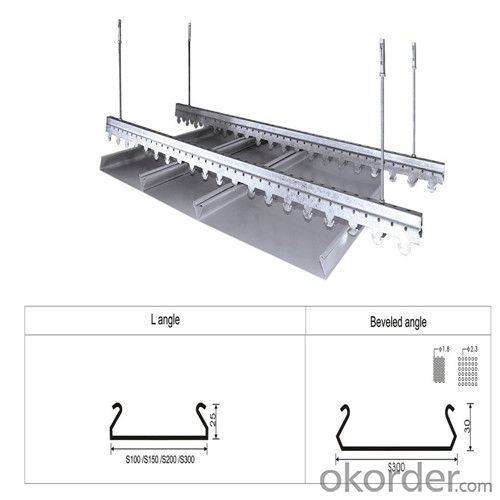

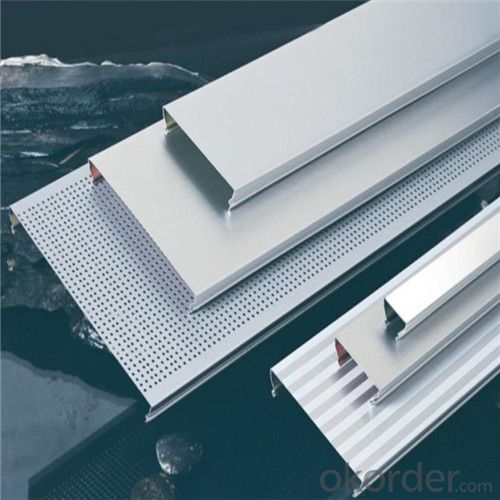

Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

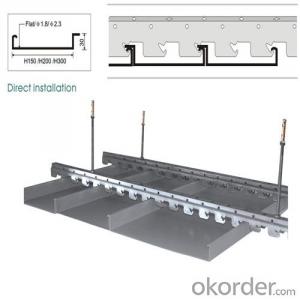

Installation and Accessories

Clip-in Concealed Metal Panel Ceiling

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

The Lay in (I) system is easy to match grid system. The panels are right angle by 8mm chamfer. It's 100% upward accessible and installed on either silhouette grids or other 9/16" (15mm) exposed tee grids, forming unique overall effect. The silhouette grids also can offset manufacturing tolerance and installation tolerance. Also, it can be combined with mineral fiber panels to present a various installation effect.

- Q: Reason: my house top floor lovers afraid of leaking to want to shop a large area of aluminum plate, but after all, is the right angle of the aluminum plate is really hurt, they want to install a 120 wide gypsum line landscaping the following, I would like to ask how to install gypsum board gypsum Line, firm, pvc gypsum line is good, or gypsum material gypsum line is good, thank you

- Pvc gypsum line is better, but need special reinforcement

- Q: The top of the kitchen ceiling of the ceiling of the ceiling

- (Open the glue and glue), and then use the glass glue to the wall and the aluminum strip of the seam filling just fine.

- Q: How to wrap the pipe with aluminum buckle?

- Construction process: Install the plastic gusset: add the sun on the wood keel, directly from the bottom of the buckle up into the installation, the method is simple, but not beautiful appearance, and the surrounding wall is not very match. Installation of aluminum-plastic plate: in the wooden keel on the nail nine PCT board, and then glue the aluminum-plastic plate stick to it. There are many colors of aluminum-plastic plate, decorated close to the effect of the disk, but the aluminum-plastic plate angle is easy to crack, so to use thicker plate.

- Q: Aluminum slab plate ceiling is not without light steel keel

- Not the gypsum board when used with light steel keel, they are keel, but not a model specifications and types.

- Q: Ordinary 600 * 600 aluminum buckle plate integrated ceiling price how much? If i do 300 * 300, the price will be cheaper?

- Ordinary home improvement are generally 300 * 300 600 * 600 is the use of more tooling, such as office buildings, schools, etc. Home improvement is certainly cheaper than the tooling

- Q: What are the benefits of using a flat aluminum plate with aluminum ceiling ceiling?

- Easy to clean, easy to clean and maintenance

- Q: What is an aluminum buckle? What place to use it, and gypsum board is different

- Ceiling aluminum slab material after more than 10 years of development, technology is also constantly updated, the first generation of products is gypsum board, mineral wool board; second generation is PVC; third generation of products is metal ceilings. And metal ceilings and aluminum slab plate came from behind, the same day, the current market is also divided into several grades of aluminum slab: the first class of aluminum-magnesium alloy, also contains part of the manganese, the biggest advantage of the material is good antioxidant capacity, At the same time because of the addition of the amount of manganese, in the strength and stiffness has improved, is the best material for the ceiling. The second type of aluminum-manganese alloy, the strength and stiffness of the plate is slightly better than the aluminum-magnesium alloy, but the antioxidant capacity of a slight shortage of the third type of aluminum alloy, the plate contains manganese, magnesium less, so its strength and stiffness are obvious Lower than the aluminum-magnesium alloy and aluminum-manganese alloy, antioxidant capacity in general.

- Q: What is the best thickness of the ceiling?

- Look at the thickness of 0.6 mm When purchasing, the most straightforward way to determine the thickness of the aluminum slab is to look at the product specifications, length, thickness and other information on the product description at a glance. Furthermore, the thickness of the aluminum slab can be judged by the naked eye and feel. In addition, some products did not meet the required thickness, the manufacturers in the aluminum plate surface spray a layer of paint to the thickness of the standard, consumers should carefully identify.

- Q: What is the angle of the ceiling? What is the inverted angle?

- If you want to do the beam and the secondary ceiling, the corners or corners of the angle to play a corner of the role

- Q: Aluminum cords hanging around the ceiling how to fight glass glue

- Glass glue is now more suitable for bonding, blocking the gap of the material. Neutral glass gel is still very soft after the basic maintenance does not appear to remove the need to remove the aluminum plate when the card can not be unloaded and damaged buckle plate. Be sure to clear the neutral glass glue completely cured (about 7 days later) and then cut off the blade more convenient.

Send your message to us

Aluminium Strip Ceiling Malaysia C-Strip Aluminum Ceiling Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords