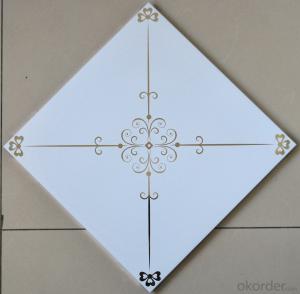

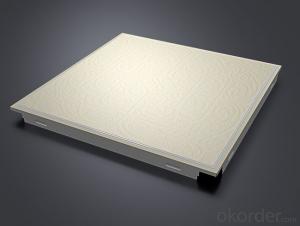

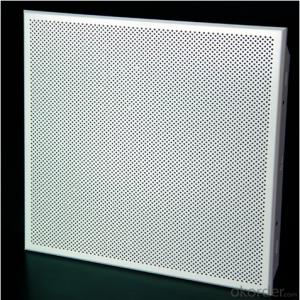

PVDF Aluminium Color Coated Wood Grain Aluminium Perforated Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

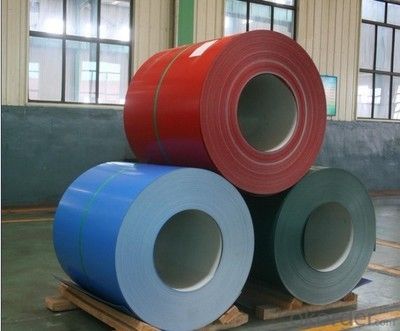

PVDF Aluminium Color Coated Coils For New Design Wood Grain

Production description

Aluminum Alloy: | AA1100,1050,1060,3003,3004,3005,3103,3105,5005,5052, 5083,5754,6061,8011,O,O-H112,ETC. |

Temper: | O,H16,H18,H22,H24,H26,H28 |

Aluminum Alloy Thickness: | 0.08mm~1.2mm(0.08,0.18,0.28,0.38,0.48,0.6,0.8,1 mm) |

(0.1,0.15,0.25,0.35,0.45 mm) | |

Coil Width: | 30~1520mm china price color coated aluminium coil |

Core Diameter: | 150/405/505mm |

Coil Weight: | 1~2.5tons each coil for 3003 colorful aluminium coil for acp |

Coating Type: | PE,PVDF,back coatting |

Surface Type: | Smooth,Embossed,mill finish,coated,brushed,etc. |

Glossness: | 10-90%(EN ISO-2813:1994) |

Coating Thickness: | PE:more than 18 +-1micron |

PVDF:more than 25+-1micron | |

Back Coating:5~7+-1micron | |

Coating Color: | Color A:pure white, ivory, white matte,yellow white,opal,light gray, aluminum natural color etc. |

Color B:blue,yellow,gray,black,dark gray etc. | |

Color C:white silver gray,flash silver,champagne etc. | |

Color D:violet,pure orange,orange,bright red,china red,dark blue, brown,green,laker blue,flash gold yellow etc. | |

Paint Hardness: | More than 2H |

Coating Adhesion: | 5J(EN ISO-2409:1994) |

Impact Resistance: | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility(T-bend): | <2t< span=""> |

MEK resistance: | More than 100 |

Salt Fog Resistance(H): | ≥500 |

Advantage: | 1.High temperature resistant 3003 colorful aluminium coil for acp |

2.Weathering resistant | |

3.Scrubbing resistant | |

4.Sound insulation | |

5.Acid or alkali proof,Fireproof | |

6.Light weight material is easy to construct and install | |

Packing Details: | Five-layer carton,strong polar fumigation wooden pallet,steel belt fastened outside,worthy shipping by sea. |

Coating Aluminum Standard: | Chemical Composite:GB/T 3190-2008,JIS,EN,ASTM, Mechanical Pr operty: GB/T 3880-2006, JIS, EN, ASTM |

Certification: | ISO9001:2008, |

Application: | acp,aluminum composite panel,roof,gutter,ceiling,facade,wall cladding, gutter,aluminum honeycomb panel,roller shutter,rolling shutter,truck body,rolling shutter door,etc. |

Packaing and Delivery

Packaging details | Standard seaworthy exporting carton, Wooden pallets,waterproof paper and plastic kraft coverage or or as per customer's requirements |

Delivery details | 25-30 days after getting your down payment |

FAQ

--Q: How can I request a product sample?

A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

--Q: How can I request a product catalog?

A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

--Q: Wha's your payment terms?

A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

--Q: What's your trade terms?

A: FOB, CNF(CFR), CIF, EXW.

--Q: How long is the quality guarantee?

A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: Exhibition hall ceiling aluminum grid 3d is how to do

- In fact, with the other curtain wall concealed works the same practice, concealed works will be closed after the invisible place to the supervision and acceptance, and confirmed on the acceptance can be, the glass curtain wall is basically covered by the part of the hidden layer of the hidden , The information around the electronic dog has.

- Q: Bathroom moisture is too heavy, I am afraid to use gypsum board will fall off, want to use aluminum buckle board, but the designer suggested that I use moisture gypsum board, we have no one know how to choose ah?

- Must use aluminum slab plate, such as the West fly and some other brands to do the aluminum plate is piano, not afraid of water, do not touch the water, and now a variety of patterns, the effect of all, unless your designer has a particularly unique design. Some designers are not professional design company, but the home improvement company, some people will design the concept of construction from the company point of view, increase the amount of construction. It seems to be heavy, but there is such a phenomenon exists, and generally.

- Q: How to remove the ceiling of the aluminum plate

- 1, square aluminum slab plate: with a hanging the kind of hook sucker sucked the middle of the buckle plate, and then pull down, down on the. 2, the strip of aluminum plate: wallpaper knife along the gap into the back and forth to draw a few, find the location of the clip, and then gently pry down, the first pry the middle of the pry on both sides of the easy deformation. 3, the side of the aluminum with a sucker from the edge of the pull down or with a small word screwdriver from the edge of the pry down; long buckle of the aluminum plate is required to remove from the last board and then removed; Kouban can be a small flattened screwdriver with the edge of the single piece of the pry down, you can remove a single piece of single plate.

- Q: Metal ceilings, including aluminum slabs and so on

- Ceiling ceiling is mainly used for airports, railway stations, office buildings, shopping malls, subway stations and residential and other places. The market has gypsum board, mineral wool board, PVC, aluminum slab plate and soft ceilings and so on. ?? The first generation of products for the gypsum board, mineral wool board; ?? Second generation of PVC; ?? The third generation is metal ceilings.

- Q: What are the specifications of the ceiling plate?

- 300 * 300 300 * 450 300 * 600 Unit mm Mainly look at your own preferences!

- Q: Aluminum buckle plate double ceiling how to seal the middle of the two

- Reach the lamp board also press out, put on the lamp, one press up into the keel

- Q: The kitchen lights in my house are broken! Ceiling lights are with the buckle board together, do not know where to start out, I would like to ask you how to get big? Need tool not? Thank you! anxious

- Do not need tools, my family is also bad, above the card, hand down can be moved down,

- Q: How can I install an aluminum cords with a ceiling?

- The correct construction sequence is like that.

- Q: What are the requirements for designing a ceiling? Note the arrangement of the main and sub keylones and hanging bars and their size requirements

- According to the specific circumstances, the specific requirements, choose a suitable aluminum ceiling: aluminum grille, aluminum veneer, aluminum buckle board, aluminum square board, integrated ceiling

- Q: My house north of the balcony to install curtains, but the above is the aluminum plate, three sides are glass, how to install curtains, or can play the curtains of other practices are also OK, but do not want to use the film.

- There is a high-strength viscosity of the B-combination can stick

Send your message to us

PVDF Aluminium Color Coated Wood Grain Aluminium Perforated Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords