Perforated Aluminium Ceiling - Beautiful Metal Ceiling Tiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 250000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications and Sizes:

1)Aluminum skin thickness: 0.12mm-0.50mm.

2)Total panel thickness: 2mm-6mm.

3) Width:1000mm,1220mm (regular), 1250mm,1300mm,1500mm,1550mm, 1575mm,2000mm(maximum);

4) Length:Up to 6500mm;

5) Standard size:1220mm(Width) ×2440mm(Length).

6)Surface Treatment:PVDF coating and PE coating.

7)Main aluminum composite wall panel Product:PE coated ACP,PVDF coated ACP,Nano PVDF coated ACP,Mirror finish ACP,Brushed ACP,Wooden ACP,Granite ACP and Fireproof core ACP.

8) Non-standard sizes and special colors are available depending on customers’ offers

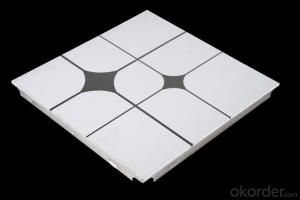

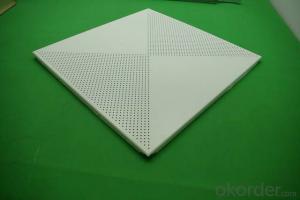

♦ Material:Grade AA aluminum ceiling plain;

♦ Thickness:0.4mm~1.05mm;

♦ Color:Matt white;

♦ Specification:300x300mm, 300x450mm, 300x600mm, 300x1200mm, 600x600mm, 600x900mm, 600x1200mm;

♦ Sound-absorption:Germany soundtex nonwoven,MRc0.65~0.8;

♦ Surface:Akzo Noble electrostatic power coating, coating thickness is 0.06~0.1mm;

♦ Installtion system:Delta-clip into the system,the A-keel the keel between systems

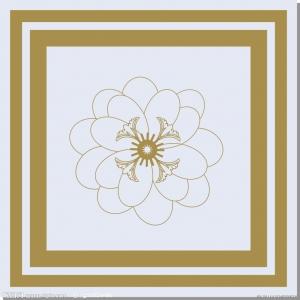

Available Colors:

We can produce all colors on all professional color cards

Feature

Super peeling strength/ Good temperature adaptability/ Excellent performance of fireproof/ Weather proof/ Quickly installed/ Excellent self-cleaning character

Applications:

1) Constructional exterior curtain walls, Wall Panel are widely used in exhibition, stores, offices, banks, hotels, restaurants and apartments;

2) Decorative renovation for storey-added old buildings, facades, roofing;

3) Indoors decoration for interior walls, ceilings, bathrooms, kitchens, balconies and subway;

4) Advertisement board, display platforms, billboards and signboards;

5) Wallboard and ceilings for tunnels;

6) Raw materials in industrial purpose;

7) Material used for vehicle bodies, yachts and boat

Pictures

- Q: Can the aluminum plate be made of walls? How to build is better, how to install the ground

- Really can not do, aluminum ceilings too thin casually hit on a lack of wall, then you can paste wallpaper ah

- Q: 600 × 600 aluminum slab plate production equipment how much money

- The price may be different in general are used in public places ... ... home decoration without the price in addition to the brand and pattern outside ... ... the most important is to see the thickness of 0.45mm-1mm have 9 yuan -20 yuan / piece about 1mm above are 30 yuan / piece above the 600 * 600 specifications, each square needs 2.78 sheets, for example: 10 square, then 10 square * 2.78 = 28 (27.8) Zhang also keel and other accessories

- Q: Aluminum slab plate 300 × 300 panel lights up to the number of watts

- 300300's routine is 24W The largest words can also reach 30W drive current can be transferred Details can be asked on the 1688 platform, China Green Fu photoelectric

- Q: Figure, 600 * 600 or 300 * 300 aluminum buckle plate can not make such a light groove, the edge is not used to close the edge of the edge? Not much, thanks for the answer!

- Side of the edge is no problem, but the aluminum plate to do this, may not be good-looking, there are two main, one is added after the light of the aluminum plate will be bright light, the second is the same as the aluminum plate will reflect the light Tube or a long time gray, ugly.

- Q: What is the difference between metal aluminum ceilings and traditional ceilings?

- Another process is different

- Q: How to distinguish between aluminum plate and what kind of board board

- Film, nano, oxide film are called aluminum plate.

- Q: What are the specifications of the aluminum ceiling?

- Acrylic is a low-grade paint (plastic), relatively hard, brittle, easy to crack when bending, in the high-end ceiling works rarely used. Polyester is a small density of plastic, with flexibility, bending strain generated. The addition of a polyurethane component to the polyester makes it soft. Aluminum Ceflon Fluorocarbon is a US-made coating material. Fluorine and carbon set, excellent stability, in the wind, rain and sun in the case will not change color, which is used for outdoor engineering excellent material.

- Q: First, the kind of home factory. What equipment is needed, how much is that good? Second, this project is now good market? Three small semi-finished processing of small workshops. Semi-finished products must be hoard goods, to store the number of varieties. Flower package. How much money is needed. Fourth, this factory shipment is really on the direct customer, or decoration company, or the ceiling shop if I want to start, his hands to build the future, understand please answer thanks How much money the equipment needs. How much money is needed to store goods?

- Guangdong aluminum veneer manufacturers 2.5mm aluminum veneer manufacturers, OKorder aluminum veneer, embossed aluminum veneer manufacturers, double curved aluminum veneer manufacturers, profiled aluminum veneer manufacturers, Fujian aluminum veneer manufacturers, OKorder aluminum veneer manufacturers, Hainan aluminum veneer manufacturers, aluminum veneer manufacturers in Chengdu, fluorocarbon spraying aluminum veneer manufacturers, aluminum veneer manufacturers in Shenyang, Mongolia Pa building materials

- Q: I do the aluminum slab plate integrated ceiling, drying rack above the flower drum top should be what glue

- Glass glue can be, in the drums around the glass glue, and then hang up the clothes rack, close to the aluminum buckle plate plane, two days on the fixed and solid, you can come down, but pay attention, do not get to the wire rope. You do not install, lift racks are best not buried inside the ceiling, maintenance is very convenient, but now look good. More harm than good

- Q: Such as the problem, the wet bathroom will be selected because of the aluminum buckle material and the formation of a layer of water droplets, Is not it should choose the sauna board and other wood materials please answer the other experts and the kitchen and before and after the balcony if you choose the aluminum plate should choose what form, Foil

- Aluminum plate must choose matte, do not light. Because it is easy to see the light is not easy to see. Balcony should be on the PVC board on it.

Send your message to us

Perforated Aluminium Ceiling - Beautiful Metal Ceiling Tiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 250000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords