Wholesale S-Shaped Strip Aluminium Ceiling Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Designed and engineered to perform in multiple commercial environments under multiple stresses,Metal Ceiling systems allow cutting-edge technologies to be applied to the most modern or traditional designs. Every component is designed and fabricated to exacting specifications and the highest manufacturing standards.

Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

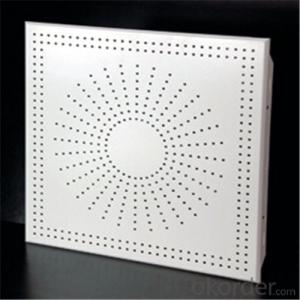

Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

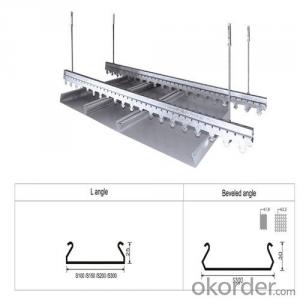

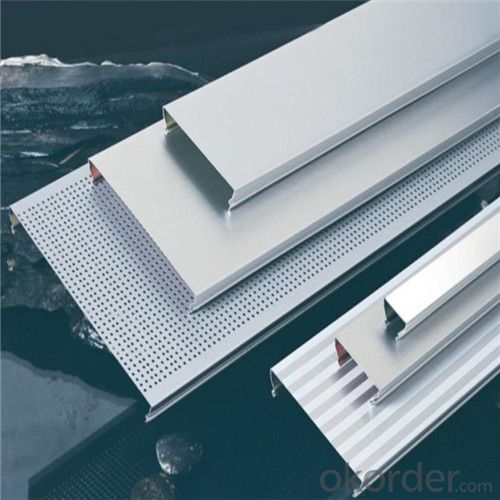

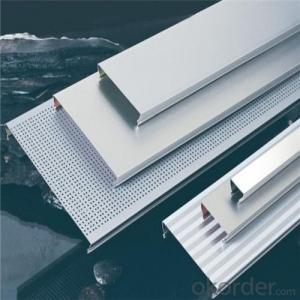

Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

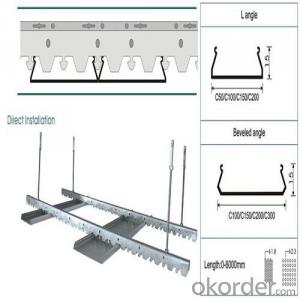

C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

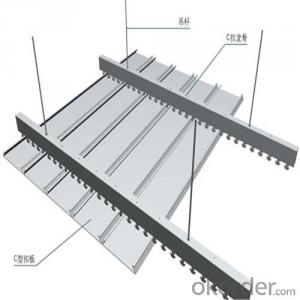

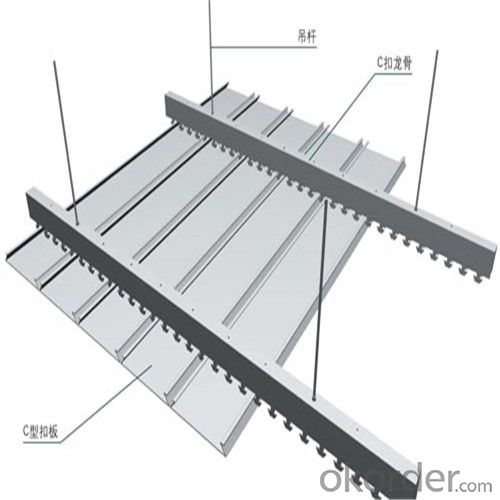

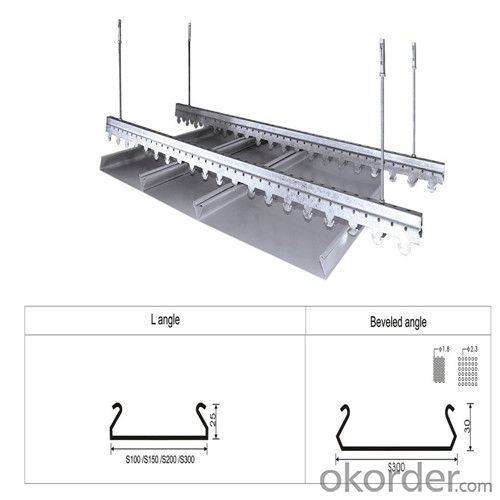

Installation and Accessories

Clip-in Concealed Metal Panel Ceiling

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

The Lay in (I) system is easy to match grid system. The panels are right angle by 8mm chamfer. It's 100% upward accessible and installed on either silhouette grids or other 9/16" (15mm) exposed tee grids, forming unique overall effect. The silhouette grids also can offset manufacturing tolerance and installation tolerance. Also, it can be combined with mineral fiber panels to present a various installation effect.

- Q: Color buckle board, that is, how to install Caigang advertising Kouban it?

- in the room around the wall to play a good level, according to the design elevation, the horizontal line as the benchmark to determine the elevation of the ceiling and line of the line, to find the center of the room, and along the ceiling elevation line to the center of the room as the center Draw a keel on the wall.

- Q: Aluminum veneer, aluminum ceiling installation to pay attention to what the problem

- The aluminum board is connected to the keel by the surrounding aluminum horn and fixed to the keel with screws. In the installation is strictly prohibited distortion, deformation, bruises, from top to bottom layer of aluminum veneer surface of the protective adhesive tape to tear off, while layer by layer synchronization split, dismantling should pay attention to protect the aluminum veneer, Scratches; pay attention to the installation of precision control, vertical vertical plane 2mm; surface flatness 3mm; corners Founder 3mm; seam straight 0.5mm. The project in the installation process in strict accordance with the requirements of construction, and adhere to the process can not be carried out on the next process of construction quality control principles. In addition to taking into account the facade of the decorative effect, but also to consider the thermal expansion of the thermal expansion after the amount of seams must be sealed with a weathering rubber to prevent gas infiltration and rain leakage ① fully clean the board The gap to ensure that the adhesive surface clean, and to dry; ② to adjust the depth of the seam, to avoid the three sides of the glue, the seam filled with PVC foam material (small round bar); ③ glue should be applied Flat, remove the excess glue; ④ pay attention to post-mortar care, glue in the incomplete hardening before, do not contaminated with dust and scratches

- Q: Thickness: 0.5,0.6,0.7.

- So thin ah your material. Generally used 0.8 good. The 0.5 of those easy to crack. Life is short ah. 120 yuan or so 1 square.

- Q: Aluminum slab ceiling price

- 600 aluminum buckle board style is simple atmosphere, then the style of 300 aluminum buckle board is small and neat, because the small lattice than the big man is more significant room quality, 600 aluminum plate in the 300 aluminum buckle plate is the truth.

- Q: Aluminum buckle board and pvc which is good

- PVC gussets: PVC gusset plate is also we often see the plastic plate, PVC gusset plate light quality, waterproof, moisture, heat insulation, not easy to burn, no dust, easy to clean, but also suitable for kitchen, bathroom ceiling decoration. But compared to metal ceiling, PVC ceiling appears to be inferior. PVC buckle advantages: 1, PVC buckle ceiling pattern more varieties, to choose from the varieties are: milky white, beige, lake blue; patterns are: Epiphyllum, flat peach, Xiong Zhu, Yunlong, grid flowers, parquet and so on. 2, the material is light weight, easy to install, waterproof and moisture-proof, anti-borer, and resistant to pollution, good cleaning, sound insulation, good insulation performance, especially in the new process by adding flame retardant material, More secure. 3, PVC gusset material cost is low, so the cost of PVC gusset ceiling is very low, while the installation is also very simple. PVC gusset plate Disadvantages: 1, the general disadvantage of plastic material is the physical performance is not stable enough, so the key problem is that even if the PVC does not encounter water, a long time will be deformed. 2, aging fast, easy to change color, short life, generally 3-5 years looks long for a long time. 3, low environmental protection, waste PVC gusset plate is difficult to deal with, causing pollution to the environment, if with a strong irritating smell of PVC gussets, the body is harmful.

- Q: How to replace the embedded led lights from the aluminum buckle ceiling

- Aluminum slabs are the easiest to install in all lights! The aluminum gusset plate is stuck on the keel, with a small screwdriver (or small blade) from the aluminum buckle seam edge tilt a corner! Slowly pull down the lampshade by hand, with the same method in the next pull down a piece of buckle, see the lamp body is stuck in the keel above, a hand to pull the keel outward, the other hand to the top of the lamp , Light on the Kai down, and know how to unload the unloading to understand how installed, and installed this kind of lamp a pliers a small screwdriver to get!

- Q: Want to open a small aluminum buckle board processing plant about how much money

- Small aluminum gusset processing plant, you need to have a plant 100-300 square of the plant, part of the production workshop, part of the inventory, the other part can be used as a sample display room. The location of the traffic to facilitate the delivery of goods on it.

- Q: I do the aluminum slab plate integrated ceiling, drying rack above the flower drum top should be what glue

- Any glue is not used to dry clothes more important fixed in the building on the ceiling

- Q: How to look good or bad

- My home renovation of the kitchen and bathroom, is the use of Geller integrated ceiling, and decoration teacher leisure time they are taught me to sub-aluminum plate is good or bad: 1, recognize aluminum plate brand: all large enterprises produce home improvement aluminum surface has a layer Own brand of protective film. 2, the name of the brand seal: all large enterprises to produce different structures keel, square aluminum plate at the end or edge will have their own brand of embossing, is the pressure of the machine can not afford to wipe. 3, look at the material: to see the aluminum is good or bad, not the thicker the better aluminum, and now most of the market on the 0.8 thick home improvement is produced by small processing plants inferior products. 4, look at the film thickness: mainly to see the ceiling covered by the membrane of the process, the film is not covered by the better the better, the general good quality film surface smooth and smooth, good reflective, long time to use the surface is not Will become wrinkled, discolored.

- Q: Aluminum Clamps Lamps 450x450

- The specifications of the lamps can be selected according to the specifications of the aluminum gusset. Generally 300 * 300,300 * 600,300 * 450 and so on. Aluminum slab plate installation method: the general buckle with a dedicated keel, keel for galvanized steel and paint steel, the standard length: 3000MM.

Send your message to us

Wholesale S-Shaped Strip Aluminium Ceiling Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords