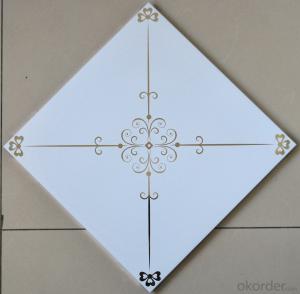

Wholesale High Quality Lay In Aluminum Ceiling Tiles/Perforated Steel Ceiling Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1.Aluminium material,fireproof,waterproof,soundproof

2.Suspended installation,won't harm the base ceiling

3.Flat non-trace,splicing seamless:

4.Each plate edge have screens orientation to ensure the ceiling smoothly and beautiful.

5.Plates joining together through by keel,which make splicing seamless and engineer cover,and moisture.

6.On the back of the ceiling with the sound-absorbing paper or cotton, make it has the best sound-absorbing function.

7.Suitable for indoor,such as office buildings, schools, hospitals,supermarket, channel, banks, etc.

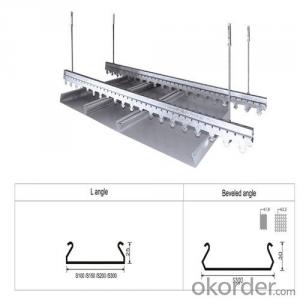

Specification of aluminum ceiling clip in tiles 600X600

| Clip-in

| Size | Height | Thickness | Edge |

(mm) | (mm) | (mm) | ||

| 300*300 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

| 300*600 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

| 300*1200 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

400*400 | 1020/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

| 500*500 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

| 600*600 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

| Lay-in | 275*275 | 8/10 | 0.45-1.0 | Straight Edge |

| 295*295 | 8/10 | 0.45-1.0 | Straight Edge | |

| 575*575 | 8/10 | 0.45-1.0 | Straight Edge | |

| 585*585 | 8/10 | 0.45-1.0 | Straight Edge | |

| 585*1185 | 8/10 | 0.45-1.0 | Straight Edge |

Specifications

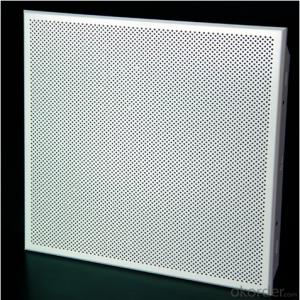

Aluminum perforated ceiling panel

1),Modern design and good quality

2)24 year experience in making ceiling

3)ISO9001,CE

Aluminum perforated ceiling panel

Detailed Product Description:

1)Material:galvanized steel or aluminium

2)Specification:600x600mm.800x800mm.300x1200mm.400x1200mm.600x1200mm

3)Thickness:0.4 to 1.2(guarantee enough)

4)Surface coating:outdoor polyester powder coating

5)Style:plane.perforated.lay-in.clip-in or as per your request

6)Packing:standard carton with Xinjing mark(wood box or hard paper is addible)

7)Quality guarantee:surface color stable for 10 years by indoor use

Product Merit:

1)Surface smoothness and easy cleaning

2)High precision.rigidity and consistency

3)Strong corrupt proof. weather proof and chemical proof

4)Surface color stable for 10 years by indoor use

5)Flexible suspension system makes each ceiling tile easily installed and disconnected

6)Easy to match lamps or other ceiling parts

7)Fireproof

Recommend places for application below

1)Supermarket.marketplace

2)Service station.toll station

3)Underground.air port,bus station

4)School.office,meeting room

5)Hall.corridor and toilet

6)Sport center

7)Office.store.plaza

8)Hotel.restaurant.kitchen.

9)Hospital

Acoustic ability:

1)Perforated with SoundTex paper

2)Absorb modulus:NRC=0.7

3)Acoustic level:

a)plain:CAC=40dB

b)perforated:CAC=24dB

Fireproof ability:pass British Standard Institution fire test(BS476)

- Q: 3DMAX in the aluminum slab ceiling how to do real? (In addition to using the map)

- Use the grid to separate the number of blocks of the aluminum plate, and then one by one map.

- Q: Thickness: 0.5,0.6,0.7.

- On the same aluminum aluminum plate from the thickness of 0.8 is better than 0.6, but the general project with aluminum slab plate is 0.8 mm, or even thicker, why? Because some of the works with a very long buckle, in order to prevent deformation, so use thicker, hardness of some, on the contrary, home improvement with aluminum slab plate, rarely more than 4 meters, and aluminum buckle on the ceiling no heavy Things, so, home improvement aluminum plate, it can be said that 0.6 mm is enough to use.

- Q: Will the bathroom ceiling plate installed on the ceiling (top grade) is not bright, how to change the light bulb? Kouban can be removed, the light can not get down.

- If not, check that the base is not fixed with screws.

- Q: What is the kind of aluminum slab ceiling? How can we see it simply?

- Pay attention to the production process At present, the market of the production process is divided into spray board, roller coating, film three. Which due to the coating with bright colors, light, water, no dust, etc., favored by many consumers, and its price is more affordable, is the economic family of the preferred aluminum slab ceiling decoration materials. However, due to some of the shortcomings of the film itself, the current coating is mostly to be replaced by a roller plate.

- Q: Nano-aluminum plate how much money a square meter

- Look at the brand, nano is just a business gimmick only, the brand is also out of advertising. There is no national standard in emerging industries.

- Q: How to choose aluminum cords plate ceiling color

- Germany wind wide line of aluminum veneer is very good, you can follow the color you like to spray, optional very much, you can help you choose for your aluminum plate.

- Q: Kitchen bathroom with aluminum slab plate can do shaped ceiling?

- Ceiling (English name: sprung roof) refers to the housing living environment of the top decoration. Simply put, refers to the decoration of the ceiling, is an important part of interior decoration. Ceiling with insulation, insulation, sound insulation, sound absorption of the role, but also electrical, ventilation and air conditioning, communications and fire, alarm pipeline equipment and other projects hidden layer. Home decoration ceiling is a common part of home improvement. The ceiling is different according to the material of the decorative plate, and the classification is not the same. Ceiling decoration materials is the main basis for distinguishing the name of the ceiling, mainly: light steel keel gypsum board ceiling, gypsum board ceiling, mineral wool board ceiling, plywood ceiling, profiled long strip of aluminum slab ceiling, Glass ceiling, aluminum honeycomb perforation sound-absorbing panels such as ceiling. In the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q: Which out of the color, better?

- Of course, the color of the color of the color plate is very high

- Q: Aluminum Clamps Lamps 450x450

- The specifications of the lamps can be selected according to the specifications of the aluminum gusset. Generally 300 * 300,300 * 600,300 * 450 and so on. Aluminum slab plate installation method: the general buckle with a dedicated keel, keel for galvanized steel and paint steel, the standard length: 3000MM.

- Q: The top of the kitchen did not line, like the largest reduction in space, at least how high Is the kitchen

- Two probabilities, one is the commercial kitchen. Commercial kitchen, then taking into account the new wind, exhaust, fire pipe will be arranged at the top of the kitchen.

Send your message to us

Wholesale High Quality Lay In Aluminum Ceiling Tiles/Perforated Steel Ceiling Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords