Metal Ceiling Tiles Lay-in Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

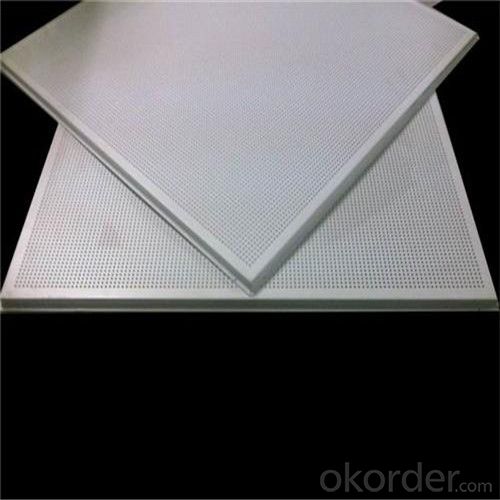

Aluminum perforated ceiling panel

1),Modern design and good quality

2)24 year experience in making ceiling

3)ISO9001,CE

Aluminum perforated ceiling panel

Detailed Product Description:

1)Material:galvanized steel or aluminium

2)Specification:600x600mm.800x800mm.300x1200mm.400x1200mm.600x1200mm

3)Thickness:0.4 to 1.2(guarantee enough)

4)Surface coating:outdoor polyester powder coating

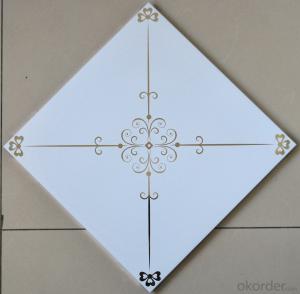

5)Style:plane.perforated.lay-in.clip-in or as per your request

6)Packing:standard carton with Xinjing mark(wood box or hard paper is addible)

7)Quality guarantee:surface color stable for 10 years by indoor use

Product Merit:

1)Surface smoothness and easy cleaning

2)High precision.rigidity and consistency

3)Strong corrupt proof. weather proof and chemical proof

4)Surface color stable for 10 years by indoor use

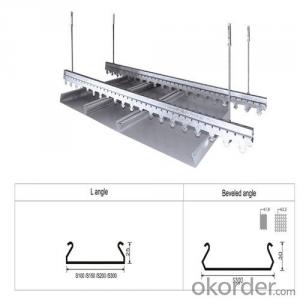

5)Flexible suspension system makes each ceiling tile easily installed and disconnected

6)Easy to match lamps or other ceiling parts

7)Fireproof

Recommend places for application below

1)Supermarket.marketplace

2)Service station.toll station

3)Underground.air port,bus station

4)School.office,meeting room

5)Hall.corridor and toilet

6)Sport center

7)Office.store.plaza

8)Hotel.restaurant.kitchen.

9)Hospital

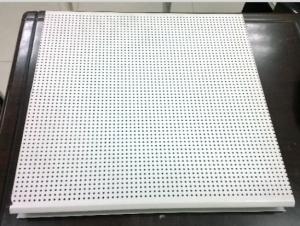

Acoustic ability:

1)Perforated with SoundTex paper

2)Absorb modulus:NRC=0.7

3)Acoustic level:

a)plain:CAC=40dB

b)perforated:CAC=24dB

Fireproof ability:pass British Standard Institution fire test(BS476)

![]()

Product Name | lay in aluminum ceiling tile |

Material | Aluminum alloy or high quality galvanized steel |

Size(mm) | 300 x300/300 x600/300 x1200/600 x600/600 x1200 or as customers' request |

Thickness | 0.45mm-1.0mm or customers'requirement |

Height | 10mm(lay in / on ceiling),18mm, 20mm (clip in ceiling) or as customers'request |

surface treatment | brushing,film coated,roll coated,spray painted etc |

Color | Standard white or customized |

Main futures | 1.Different Perforation and surface are available |

2. Sound absorbing. The circle in surface is help to reduce the noise, keeping a silent surrounding. | |

3.simple structure, good adhesion,Easy install and disassemble | |

4.anti-corrosion, fireproof, waterproof, rust proof, weather resistance | |

5.easy cleaning, highly recyclable, easy maintenance, durable, anti-ultraviolet, radiation proof. | |

Application | Kitchen, bathroom, living room, office, shopping mall, conference room, laboratory, exhibition hall, airport and so on |

certificate | ISO9001:2000 ,SONCAP ,SGS. CE ,ROHS,TUV etc |

- Q: How to sub-aluminum buckle plate is good or bad?

- Look at the keel: keel is good or bad is a lot of consumers ignore the problem, the keel material is generally divided into aluminum, iron and no fingerprint steel. Aluminum keel will not rust, but because the cost is relatively high sales so very little. Iron keel is easy to rust, although the keel section hidden in the back of the ceiling generally do not see, but the rust scattered on the ceiling on the ceiling is not good, over time will affect the stability of the ceiling. No fingerprint steel keel relative to the iron keel it is not so easy to rust, is currently the most commonly used home improvement tooling sales. I sincerely hope that consumers can buy their own ideal integrated ceiling products.

- Q: Thickness: 0.5,0.6,0.7.

- So thin ah your material. Generally used 0.8 good. The 0.5 of those easy to crack. Life is short ah. 120 yuan or so 1 square.

- Q: How does the kitchen pick aluminum ceilings?

- Kitchen aluminum buckle ceiling is best to choose flat type. Kitchen smoke and more clean is a big project, you can choose nano-anti-fouling. Kitchen aluminum plate also pay attention to fire resistance and moisture resistance.

- Q: The designer advised us to use the gypsum board on the toilet, said nice, the atmosphere. Because we are in the top floor, does not affect the leakage, we first decoration, good tangled, such as gypsum board, then the cost will be much higher? Please experts to give advice.

- Some designers he only know to visual effects, in fact, do not understand anything.

- Q: Magnet suction does not suck aluminum buckle plate?

- Aluminum plate surface is like a wallpaper, like the lines, sucker surface can not be fully contact with the paste, resulting in the suction cup can not form a vacuum inside, so sucker suck, for such a situation can use the suction cup stickers, this is a smooth side There is a sticky thin skin, the sucker auxiliary paste affixed to the rough surface, the formation of a chuck for the use of a smooth table ...

- Q: What brand of aluminum plate is good, which brand of aluminum buckle plate is better?

- Aluminum slab is actually a ceiling, but also the current decoration more use of a ceiling, we all know that many products are not guaranteed, so in the selection of materials should pay attention to a well-known brand of aluminum slab ceiling and the same other Brand of aluminum slab ceiling compared to the total there are some leading technology, quality is also guaranteed.

- Q: It is good for smallpox and aluminum buckets

- According to the aluminum gusset process sub-sprayed aluminum plate, roller coated aluminum plate, covered with aluminum slab three categories, followed by a further increase in life cycle, increased performance. Sprayed aluminum slabs of the normal consumption of 5 to 10 years, roll aluminum plate for 7-15 years, covered with aluminum slab for 10-30 years.

- Q: Aluminum cords hanging ceiling and plastic buckle ceiling which is good?

- First, the demolition, installation, maintenance are convenient, easy to install lamps; ?????? Second, the aluminum plate hanging ceiling waterproof, high temperature resistance than plastic top good; ????? Third, aluminum slabs look good, modeling can be parquet and other choice of space, and plastic is relatively no choice for a lot of room.

- Q: Aluminum buckle ceiling ceiling how to do

- The card into the place to get closer, or the edge of the aluminum plate bent a little bit after the card into the just fine, you try

- Q: What is an aluminum buckle? What place to use it, and gypsum board is different

- Often said that the aluminum plate is used to the kitchen and the bathroom ceiling, the specifications are mainly 300 * 300, a lot of color, commonly used in white and silver, matching accessories are light steel keel and paint corners;

Send your message to us

Metal Ceiling Tiles Lay-in Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords