Wholesale Roofing Aluminum Coil - Aluminum Mill Finished Strips 8xxx for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 g/ft

- Supply Capability:

- 100000 g/ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Mill Finished strips 8XXX Used in Construction Description

Aluminum Mill Finished strips 8XXX Used in Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Mill Finished strips 8XXX Used in Construction is widely used for PP cap stock, hot rolled thick plate, PS base plate, aluminum curtain wall base plate, the traffic sign ,air-conditioner heat and exchangers, food container, household foil, pharmaceutical packing, cigarettes packing.

2.Main Features of Aluminum Mill Finished strips 8XXX Used in Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

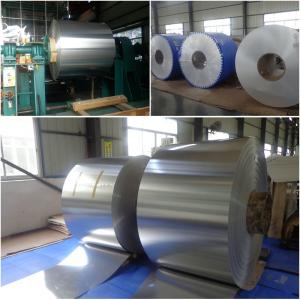

3.Aluminum Mill Finished strips 8XXX Used in Construction Images

4.Aluminum Mill Finished strips 8XXX Used in Construction Specification

Alloy | AA8xxx (AA8011 etc) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Mill Finished strips 8XXX Used in Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Mill Finished strips 8XXX Used in Construction.

B.When will you deliver the products?

Aluminum Mill Finished strips 8XXX Used in Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: How do aluminum coils contribute to reduced material waste?

- There are several ways in which aluminum coils contribute to the reduction of material waste. Firstly, aluminum is a material that can be recycled multiple times without losing its properties. This recyclability feature alone helps to reduce material waste as it eliminates the need for extracting and producing new aluminum. Moreover, industries that require precision and efficiency, such as automobile manufacturing, HVAC systems, and electrical equipment, often utilize aluminum coils. These coils can be easily tailored to meet specific requirements, minimizing the use of excess material and reducing waste. Furthermore, aluminum coils have a high strength-to-weight ratio, meaning they can be manufactured using less material while still maintaining the desired strength and durability. This lightweight characteristic not only reduces material waste but also allows for more efficient transportation and installation processes, resulting in lower fuel consumption and less environmental impact. In addition, aluminum coils can be designed to have a longer lifespan and improved resistance to corrosion. This durability factor helps to minimize the need for frequent replacement, thereby reducing material waste over time. Furthermore, the long lifespan of aluminum coils makes them an appealing choice for sustainable construction practices, further contributing to waste reduction in the long term. Overall, the utilization of aluminum coils in various industries not only promotes recycling and reusability but also enables efficient customization, lightweight construction, enhanced durability, and extended lifespan. These factors collectively contribute to the reduction of material waste, making aluminum coils an environmentally-friendly option.

- Q: This question asks for the distinctions between two types of metal coils: aluminum and iron.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has good electrical conductivity, making it ideal for applications like electrical wiring and packaging. Iron coil, on the other hand, is heavier, stronger, and more magnetic, commonly used in construction and manufacturing for reinforcement and structural support. Additionally, iron is more prone to rust compared to aluminum, which is more resistant to corrosion. The cost and availability of these materials also vary, with aluminum being more abundant and less expensive than iron.</p>

- Q: What are the common alloys used in aluminum coil production?

- The common alloys used in aluminum coil production are 3003, 3105, 5052, and 6061.

- Q: Tossing away an aluminum can wastes as much energy as pouring out half of that can’s volume of gasoline.what does that mean?

- Since aluminum is melted down recycle it is easier to melt down cans as we know.To extract the aluminum from the earth takes more to process there for volume of gas cost more;

- Q: This question asks for a comparison of various types of insulation materials, highlighting their unique characteristics and differences.

- <p>Different types of insulation materials vary in their properties such as thermal resistance (R-value), fire resistance, moisture resistance, and environmental impact. Fiberglass is a common, cost-effective option with good thermal resistance but can be irritating to the skin and respiratory system. Cellulose insulation is made from recycled paper and has good sound absorption but may be less fire resistant. Foam insulation like spray foam offers excellent insulation and air sealing but can be more expensive and harder to install. Mineral wool is fire-resistant and durable but may be less thermally efficient. Each type has its advantages and drawbacks, and the choice depends on factors like cost, environmental impact, and specific insulation needs.</p>

- Q: What is the primary substance that constitutes an aluminum coil?

- <p>The material of aluminum coil is aluminum, a lightweight, corrosion-resistant, and malleable metal. It is commonly used in various industries due to its excellent electrical conductivity, thermal conductivity, and formability. Aluminum coils are made by rolling aluminum sheets into cylindrical shapes, which can be further processed into different products such as cans, foils, and other applications.</p>

- Q: Can aluminum coils be used for radiation shielding?

- Yes, aluminum coils can be used for radiation shielding. Aluminum is often used as a shielding material due to its high atomic number and excellent attenuation properties, which effectively block and absorb radiation. It is commonly used in various industries, including medical, nuclear, and aerospace, for shielding against different types of radiation such as X-rays and gamma rays.

- Q: How do aluminum coils resist corrosion?

- Aluminum coils are able to resist corrosion due to their unique chemical composition and protective oxide layer. Aluminum is a highly reactive metal, but it forms a thin layer of aluminum oxide on its surface when exposed to air. This oxide layer acts as a protective barrier, preventing further reaction with the environment. This layer is self-repairing and continues to form even when it gets damaged, providing long-lasting protection against corrosion. Additionally, aluminum coils can be further protected by applying coatings or treatments that enhance their resistance to corrosion. These coatings act as an additional layer of defense, shielding the coils from potential corrosive agents. Overall, the combination of the natural oxide layer and optional coatings makes aluminum coils highly resistant to corrosion, ensuring their durability and longevity in various applications.

- Q: Can aluminum coils be customized?

- Yes, aluminum coils can be customized. They can be manufactured in various sizes, thicknesses, and shapes to meet specific requirements and applications. Additionally, they can undergo surface treatments, such as coatings or finishes, to enhance corrosion resistance or aesthetic appearance.

- Q: Can aluminum coils be used for electronic enclosures?

- Indeed, electronic enclosures can utilize aluminum coils. The lightweight characteristic, remarkable thermal conductivity, and corrosion resistance render aluminum a favored option. These coils can be effortlessly molded into diverse dimensions and configurations, making them exceptionally suitable for personalized enclosure designs. Moreover, aluminum exhibits electromagnetic shielding qualities, effectively safeguarding delicate electronic components against external disturbances. All in all, aluminum coils prove to be a fitting alternative for electronic enclosures, offering durability, functionality, and aesthetic allure.

Send your message to us

Wholesale Roofing Aluminum Coil - Aluminum Mill Finished Strips 8xxx for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 g/ft

- Supply Capability:

- 100000 g/ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords