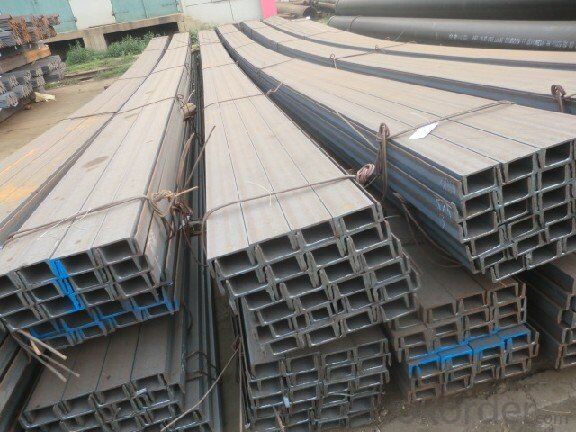

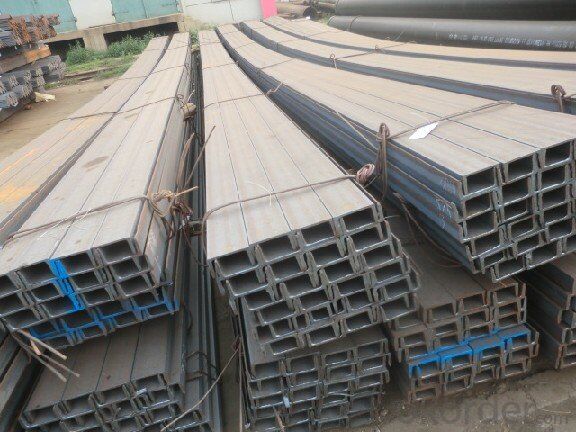

Wholesale High Grade Quality U Channel Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

high quality Hot Rolled Steel U Beam at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm |

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Product Applications:

Hot Rolled Steel U-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel U-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

- Q: How do steel channels contribute to the overall safety of a structure during earthquakes?

- Steel channels contribute to the overall safety of a structure during earthquakes by providing additional structural support and resistance to lateral forces. They help distribute the seismic energy more evenly throughout the structure, preventing localized damage and potential collapse. The channels act as bracing elements, increasing the stiffness and rigidity of the building, which reduces the chances of structural failure during seismic events.

- Q: What are the guidelines for steel channel installations in seismic zones?

- To ensure the structural integrity and safety of buildings during seismic events, it is crucial to follow guidelines for steel channel installations in seismic zones. These guidelines are developed based on engineering principles, regulatory bodies, and industry standards. 1. Considerations for Design: When designing steel channel installations in seismic zones, it is important to consider seismic forces, building geometry, and structural connections. A qualified structural engineer should be responsible for the design, taking into account project-specific requirements. 2. Material Selection: It is recommended to use high-quality steel channels that meet the specifications outlined in relevant standards such as ASTM A36 or ASTM A572. Before installation, the channels should be inspected for defects. 3. Connection Details: Proper connection details are essential for withstanding seismic forces. Welding or bolting should be done following approved methods and standards. Connections should be designed to resist both vertical and lateral forces, ensuring overall structure stability. 4. Anchorage: Steel channel installations should be securely anchored to the building's foundation or structural system. Design specifications should dictate the use of anchor bolts or other approved anchorage methods capable of withstanding anticipated seismic forces. 5. Seismic Bracing: Additional bracing may be necessary in seismic zones to enhance the stability of steel channel installations. Diagonal braces or moment frames should be designed and installed to resist lateral forces. The bracing layout and connections should comply with relevant codes and standards. 6. Inspection and Quality Control: Qualified personnel should regularly inspect steel channel installations to ensure compliance with design specifications and codes. Quality control measures should be implemented to monitor the manufacturing, fabrication, and installation processes. 7. Compliance with Local Codes: Familiarity with and adherence to specific seismic design codes and regulations in the project's location is essential. Consultation with local building authorities is necessary to meet all applicable requirements. Ultimately, the guidelines for steel channel installations in seismic zones aim to create safe and resilient structures capable of withstanding seismic forces. Engaging the expertise of qualified professionals, such as structural engineers, is crucial to accurately follow the guidelines and meet necessary standards.

- Q: Are steel channels suitable for use in industrial settings?

- Yes, steel channels are highly suitable for use in industrial settings. Steel channels are versatile and robust structural components that provide excellent strength and stability, making them an ideal choice for various applications in industrial environments. One of the key advantages of steel channels is their high load-bearing capacity. Industrial settings often involve heavy machinery, equipment, and materials, which require strong and durable support structures. Steel channels can withstand significant loads and provide a reliable framework for various industrial operations. Moreover, steel channels are known for their resistance to corrosion and weathering. Industrial settings frequently expose materials to harsh conditions, such as moisture, chemicals, and extreme temperatures. Steel channels, especially those made from corrosion-resistant alloys, can withstand these environmental challenges and maintain their structural integrity over time. Another important factor that makes steel channels suitable for industrial settings is their versatility. Steel channels come in various shapes, sizes, and thicknesses, allowing them to be adapted to different requirements and applications. They can be easily fabricated, cut, and welded to create customized structures that meet specific industrial needs. Furthermore, steel channels offer excellent fire resistance, which is crucial in industrial environments where fire hazards are a concern. Steel has a high melting point and does not contribute to the spread of flames, making it a safe choice for industrial structures. In addition to their technical advantages, steel channels are also cost-effective in the long run. Steel is a durable material that requires minimal maintenance, reducing the need for frequent repairs or replacements. Moreover, steel is widely available and can be recycled, making it an environmentally friendly choice. In conclusion, steel channels are highly suitable for use in industrial settings due to their strength, durability, resistance to corrosion and fire, versatility, and cost-effectiveness. Whether it's for supporting heavy loads, creating customized structures, or withstanding harsh environments, steel channels offer reliable and efficient solutions for various industrial applications.

- Q: What are the considerations for steel channel connections to timber structures?

- When considering steel channel connections to timber structures, there are a few important factors to take into account. These considerations include the compatibility of materials, load capacity, joint design, and potential for corrosion. First and foremost, it is crucial to ensure that the steel channel and timber are compatible materials. This involves assessing the mechanical properties of both materials, such as their strength and stiffness. Additionally, any potential chemical reactions between the materials should be considered to avoid corrosion or degradation. The load capacity of the connection is another crucial consideration. The steel channel must be able to support the anticipated loads without compromising the structural integrity of the timber. This requires a thorough analysis of the applied loads, including static and dynamic forces, as well as any potential impact or wind loads. The design of the joint is also critical for a successful connection. The steel channel should be properly sized and positioned to distribute the loads evenly across the timber members. This may involve using appropriate fasteners, such as bolts or screws, and ensuring that they are properly installed and tightened to achieve the desired level of connection strength. Finally, the potential for corrosion should be carefully evaluated. Steel is susceptible to corrosion when exposed to moisture or chemicals, which can weaken the connection over time. Proper protective measures, such as galvanizing or coating the steel channel, should be considered to prevent corrosion and extend the lifespan of the connection. Overall, when connecting steel channels to timber structures, it is essential to consider material compatibility, load capacity, joint design, and corrosion prevention to ensure a safe and durable connection. By addressing these considerations, the connection can effectively transfer loads and maintain the structural integrity of the timber structure.

- Q: Can steel channels be used for conveyor supports?

- Yes, steel channels can be used for conveyor supports. Steel channels are often chosen for their strength and durability, making them suitable for supporting conveyor systems that carry heavy loads.

- Q: What are the factors to consider when determining the appropriate angle of a steel channel?

- There are several factors to consider when determining the appropriate angle of a steel channel, including the load it will bear, the structural requirements, the desired strength and stability, the available space for installation, and any specific design or aesthetic considerations.

- Q: What do you mean by channel 8 A?

- 8# refers to the diameter of the channel, (MM) A, I have not heard of, perhaps I am not professional, channel steel used by me

- Q: 14 of channel steel and 12 of I-beam which force?

- The mechanical parameters of 14 channel steel are larger than that of 12, including the moment of inertia, the radius of inertia and the coefficient of cross section. Therefore, the same length of 14 channel steel can bear a greater force.

- Q: How do steel channels hold up against extreme temperatures?

- Steel channels are renowned for their exceptional strength and durability, rendering them highly capable of enduring extreme temperatures. The unique properties of steel, including its high melting point and thermal conductivity, enable steel channels to retain their structural integrity even in the face of extreme heat or cold. When subjected to high temperatures, steel channels exhibit a slower rate of expansion compared to other materials, thereby minimizing the risk of deformation or failure. This resistance to thermal expansion stems from the low coefficient of linear expansion inherent in steel. This property ensures that steel channels retain their shape and structural stability even amidst drastic temperature fluctuations. Moreover, steel channels boast excellent fire resistance. Steel possesses a high melting point, typically ranging from 1370°C to 1530°C (2500°F to 2800°F), thereby allowing it to withstand intense heat without compromising its structural integrity. Consequently, steel channels emerge as a dependable choice in applications where fire protection holds utmost importance, such as in buildings, bridges, or industrial structures. Conversely, steel also exhibits commendable performance in cold temperatures. Unlike certain materials that become brittle or weak when exposed to low temperatures, steel maintains its strength and ductility. Consequently, steel channels prove suitable for utilization in environments characterized by extremely cold temperatures, such as in arctic regions or cryogenic facilities. In conclusion, steel channels exhibit remarkable resilience to extreme temperatures owing to their low coefficient of linear expansion, high melting point, and overall durability. Regardless of exposure to intense heat or cold, steel channels retain their structural integrity and deliver long-lasting performance, thereby positioning themselves as a dependable choice in diverse applications.

- Q: According to the standard, indoor hanging stone 3 meters high, whether to add channel?

- The key is to see your wall!! If it's a load-bearing wall. That won't be necessary

Send your message to us

Wholesale High Grade Quality U Channel Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords