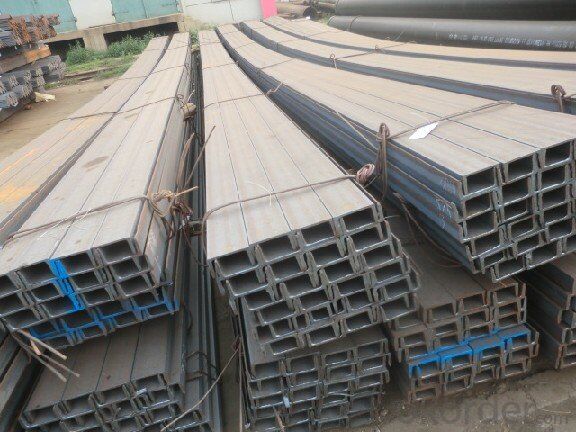

Hot Selling A Grade Quality U Channel Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

high quality Hot Rolled Steel U Beam at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm |

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Product Applications:

Hot Rolled Steel U-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel U-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

- Q: Can steel channels be used in commercial construction?

- Yes, steel channels can be used in commercial construction. Steel channels provide structural support and are commonly used in framing systems, roof trusses, and as structural elements in walls and floors. They are versatile, durable, and offer excellent load-bearing capabilities, making them suitable for various commercial building applications.

- Q: 120*53*5.5 what's the weight of channel steel?

- Should be the standard channel 12.5X53X5.5D weight is 12.318 kg per meter.

- Q: What are the common challenges in the installation of steel channels?

- There are several common challenges that can arise during the installation of steel channels. Firstly, ensuring proper alignment and positioning of the channels can be a challenge. Steel channels need to be accurately placed and leveled to ensure the structural integrity of the installation. Any misalignment can lead to issues such as uneven load distribution or reduced strength. Secondly, the weight and size of steel channels can pose logistical challenges. These channels are often heavy and require specialized equipment or machinery for handling and installation. Lack of proper equipment or expertise can lead to delays or accidents during the installation process. Another challenge is the need for proper fastening and connection of steel channels. It is crucial to use appropriate fasteners and techniques to securely attach the channels to the supporting structure. Failure to do so can result in weak connections, which can compromise the stability and safety of the installation. Furthermore, environmental factors can also pose challenges during the installation of steel channels. Weather conditions such as extreme temperatures, high winds, or heavy rain can affect the installation process. Special precautions may be required to protect the channels from corrosion or damage caused by exposure to the elements. Lastly, coordination and communication among the installation team members are essential to ensure a smooth installation process. Proper planning, clear instructions, and effective teamwork are vital to overcome any challenges that may arise during the installation of steel channels. Overall, while the installation of steel channels offers numerous benefits in terms of strength and durability, it is crucial to be aware of and address these common challenges to ensure a successful and safe installation.

- Q: How do steel channels contribute to the overall accessibility of a structure?

- Steel channels contribute to the overall accessibility of a structure in several ways. First and foremost, steel channels are often used as support beams or columns in the construction of buildings and bridges. These channels provide structural integrity and stability, allowing for the creation of open spaces and wide doorways that enhance accessibility. Additionally, steel channels can be utilized to create ramps or walkways that facilitate movement for individuals with mobility impairments. By using steel channels as the framework for these accessibility features, architects and engineers can ensure that they are strong enough to support the weight of wheelchairs or other assistive devices. Furthermore, steel channels are often employed in the construction of elevators and escalators, which are crucial elements for improving accessibility in multi-story buildings. These channels form the framework for the track systems that allow elevators and escalators to operate smoothly and safely, enabling people with mobility challenges to navigate between different levels easily. Moreover, steel channels can be used to create handrails or guardrails along staircases, ramps, or walkways. These safety features provide support and stability for individuals with disabilities or those who may have difficulty with balance, ensuring that they can move around the structure securely. Overall, steel channels play a vital role in the overall accessibility of a structure by providing structural support, facilitating the construction of ramps and walkways, enabling the installation of elevators and escalators, and creating safety features such as handrails and guardrails. These contributions enhance the accessibility of a structure, making it more inclusive and accommodating for individuals with disabilities or limited mobility.

- Q: How do steel channels contribute to the overall stability of a structure?

- Steel channels contribute to the overall stability of a structure in several ways. Firstly, steel channels provide structural support and reinforcement, distributing the load throughout the structure and preventing excessive deflection or deformation. The unique shape of a steel channel, with its flanges and web, offers increased strength and rigidity compared to other structural components. This allows the channels to resist bending, twisting, and buckling forces, ensuring the stability of the structure under various types of loads. Moreover, steel channels are often used as beams or columns, providing vertical support and enhancing the overall stability of a structure. When used as beams, steel channels can span long distances and carry heavy loads, minimizing the need for additional support structures. As columns, steel channels help transfer the vertical loads from the upper levels of the structure to the foundation, maintaining stability and preventing collapse. Additionally, steel channels can be interconnected to form trusses, which are highly efficient in distributing loads and resisting lateral forces such as wind or seismic activity. These trusses effectively transfer the loads to the foundation, ensuring the stability of the entire structure. Furthermore, steel channels can be used in combination with other structural elements, such as steel plates or concrete, to create composite sections that enhance stability and overall structural integrity. In summary, steel channels are crucial components in the construction industry, as they contribute significantly to the overall stability of a structure. Their ability to support heavy loads, resist deformation, and distribute forces efficiently makes them indispensable in ensuring the structural integrity and safety of buildings, bridges, and various other types of infrastructure.

- Q: What are the advantages of using steel channels?

- There are several advantages to using steel channels in various construction and structural applications. Firstly, steel channels are known for their excellent strength and durability. They can withstand heavy loads and provide structural stability, making them suitable for supporting beams, columns, and other load-bearing elements in buildings and bridges. Another advantage of steel channels is their versatility. They come in various sizes and shapes, allowing for flexibility in design and construction. Steel channels can be easily cut, welded, and manipulated to fit specific requirements, making them a preferred choice for customized structures. Steel channels also offer excellent fire resistance. As a non-combustible material, steel does not contribute to the spread of fire, providing increased safety in buildings. Moreover, steel channels are resistant to corrosion, rust, and decay, making them suitable for both indoor and outdoor applications. This resistance to environmental factors ensures the longevity and low maintenance of structures using steel channels. Furthermore, steel channels are cost-effective in the long run. While the initial investment may be higher compared to other materials, their durability and low maintenance requirements result in reduced repair and replacement costs over time. Additionally, steel is a recyclable material, making it an environmentally friendly choice. Lastly, steel channels have a high aesthetic appeal. The sleek and modern appearance of steel can enhance the visual appeal of structures, making them a preferred choice for architects and designers. In conclusion, the advantages of using steel channels include their strength, versatility, fire resistance, corrosion resistance, cost-effectiveness, and aesthetic appeal. These factors make steel channels a popular choice in various construction and structural applications.

- Q: What does channel specification "MQ-41" mean?

- The raw material for producing channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The finished channel steel is delivered by hot forming, normalizing or hot rolling. The specifications are expressed in millimeters of height (H) * leg width (b) * waist thickness (d), such as 100*48*5.3, which means waist height is 100 mm, leg width is 48 mm, waist thickness is 5.3 mm channel, or 10# channel steel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25#a, 25#b, 25#c and so on.

- Q: Are steel channels suitable for high-rise construction?

- Yes, steel channels are suitable for high-rise construction. Steel channels provide structural strength, durability, and resistance to fire, making them an ideal choice for supporting heavy loads and tall structures. They can withstand the vertical and lateral forces experienced in high-rise buildings, ensuring stability and safety. Additionally, steel channels can be customized to meet specific design requirements, making them highly versatile for use in various high-rise construction applications.

- Q: What are the different types of connections used with steel channels?

- There are several types of connections used with steel channels, including welding, bolting, and using steel channel connectors.

- Q: The back of the channel steel deviates from the 30mm. The upper and lower iron plates are welded at intervals. Is the cross section resistance moment the sum of the two? No, is it big or small? Thank you

- Elder brother?! The general channel without you so used, if used together with 2 channels, to groove is used, it can not be like you said with the back to back, with the flexural performance of steel greatly reduced so that you see the cement rod, hollow slab, steel pipe was use, so as to get more with less weight material bearing.

Send your message to us

Hot Selling A Grade Quality U Channel Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords