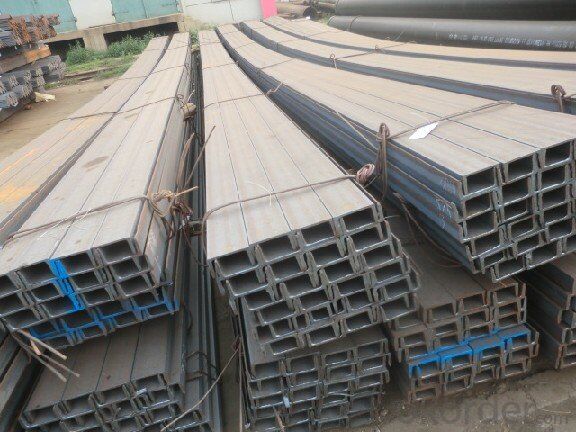

Wholesale 2015 High Quality Structure Steel U Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

high quality Hot Rolled Steel U Beam at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm |

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Product Applications:

Hot Rolled Steel U-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel U-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

- Q: How do steel channels contribute to the overall safety of a structure during floods?

- Steel channels can contribute to the overall safety of a structure during floods by providing structural support and reinforcement. These channels, which are often integrated into the building's framework, help distribute and withstand the water pressure exerted by floodwaters, minimizing the risk of structural collapse. Additionally, steel channels can be designed to elevate critical components of the structure, such as electrical systems or important equipment, above flood levels, preventing damage and ensuring functionality during and after the flood event.

- Q: What are the different types of steel channel connections used in industrial buildings?

- There are several types of steel channel connections used in industrial buildings. Some common examples include bolted connections, welded connections, and moment connections. Bolted connections involve using bolts and nuts to secure the channels together, while welded connections involve joining the channels through welding. Moment connections, on the other hand, are more complex and are designed to resist bending moments in the structure. These connections typically involve additional plates and welding to provide stability and strength.

- Q: What are the corrosion resistance properties of steel channels?

- Steel channels exhibit outstanding corrosion resistance characteristics, rendering them highly suitable for a variety of applications. The primary reason behind the corrosion resistance of steel channels is the existence of a protective oxide layer on their surface, which develops naturally upon exposure to oxygen in the atmosphere. This layer acts as a barrier, effectively preventing any further corrosion. Moreover, the corrosion resistance of steel channels can be further enhanced through the application of additional coatings or treatments. A common method used to protect steel channels from corrosion is galvanization, whereby a layer of zinc is applied to the channels. This zinc layer serves as a sacrificial shield, effectively preventing direct contact between the steel and corrosive elements. In addition, stainless steel channels offer exceptional resistance to corrosion. These channels are composed of an alloy containing a high percentage of chromium, which leads to the formation of a thin, transparent oxide layer on the surface. This oxide layer provides superior protection against corrosion caused by moisture, chemicals, and various environmental factors. On the whole, steel channels possess exemplary corrosion resistance properties, establishing them as a dependable choice for applications where exposure to corrosive elements is a concern. Whether it be through the natural oxide layer, galvanization, or the utilization of stainless steel alloys, steel channels offer long-lasting durability and reliable protection against corrosion.

- Q: Difference between light channel steel and ordinary channel steel

- Light channel steel and ordinary channel compared to the same height, other sizes are thinner than ordinary channel, the natural weight is lighter. You can also compare them with the hardware manual.

- Q: Are steel channels suitable for railway infrastructure projects?

- Indeed, steel channels are a fitting choice for railway infrastructure projects. Their high strength and durability make them a common selection in such projects. Steel channels possess the ability to bear heavy loads and impart stability to the railway structure. Furthermore, steel channels exhibit remarkable resistance to corrosion and can endure harsh weather, rendering them perfect for outdoor usage. Moreover, the ease of fabrication and installation of steel channels aids in expediting the construction process. Ultimately, the incorporation of steel channels in railway infrastructure projects guarantees the safety and longevity of the railway system.

- Q: What are the different types of welding for steel channels?

- There are several different types of welding commonly used for steel channels, including MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and stick welding. Each method has its own advantages and is chosen based on factors such as the thickness of the steel, the desired weld quality, and the available equipment and expertise. MIG welding is often preferred for its speed and ease of use, while TIG welding offers better control and produces cleaner welds. Stick welding, on the other hand, is a versatile method suitable for a wide range of steel thicknesses and can be used in outdoor or remote locations.

- Q: What are the different methods of surface preparation for steel channels?

- Some of the different methods of surface preparation for steel channels include abrasive blasting, phosphating, pickling, and acid cleaning. These methods are used to remove any rust, scale, or other contaminants from the surface of the steel channels, ensuring proper adhesion of coatings and promoting corrosion resistance.

- Q: What are the different methods for cutting steel channels?

- There are several methods for cutting steel channels, including manual methods such as hacksaw or chisel, power tools like angle grinders or reciprocating saws, and more advanced methods like plasma cutting or water jet cutting. The choice of method depends on factors such as the thickness and type of steel, desired precision, and available equipment.

- Q: What is the difference between steel tubes such as channel steel and square tube?

- Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. Channel steel is mainly used for building structures, vehicle manufacturing, other industrial structures and fixed plates, cabinets, etc., and channel steel is often used in conjunction with i-beam.

- Q: What is the significance of the dimensions of steel channels?

- The importance of steel channel dimensions can be attributed to several factors. To begin with, the structural integrity and strength of a steel channel depend on its dimensions. Steel channels are commonly employed in construction and engineering projects to offer support and stability. By determining the height, width, and thickness, these dimensions ascertain the channel's ability to withstand weight and loads without distortion or collapse. Consequently, selecting appropriate dimensions is crucial to guarantee the channel's effective performance in its intended function. Moreover, the dimensions of steel channels also play a role in their versatility and compatibility with other building components. Standardized dimensions are often preferred as they seamlessly fit into existing structural systems, thus streamlining construction and assembly. Additionally, the dimensions of steel channels must be compatible with other materials or components, like bolts or fasteners. Ensuring a proper match of dimensions establishes a secure and smooth connection between various elements, thereby enhancing the overall stability and durability of the structure. Furthermore, the dimensions of steel channels can influence their cost and availability. Manufacturing processes may vary depending on the dimensions, which in turn affect production costs. Additionally, certain dimensions are more commonly produced or stocked by suppliers, making them more readily available and cost-effective compared to customized or non-standard sizes. Lastly, the dimensions of steel channels can also have aesthetic considerations. In architectural and design applications, the dimensions of steel channels contribute to the overall appearance and style of a structure. The proportions and arrangements of channels can create visual interest, specific architectural effects, or align with particular design styles or preferences. In summary, the importance of steel channel dimensions lies in their impact on structural integrity, versatility, compatibility, cost, availability, and aesthetics. Thoughtful consideration of these dimensions ensures that steel channels meet the requirements of a project, providing a robust and dependable support system for various applications.

Send your message to us

Wholesale 2015 High Quality Structure Steel U Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords