Wholesale Blue Coated Aluminum Foil Coil for Insulated Panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Blue Coated Aluminium Foils Used for Insulated Panels

We specialize in Blue Coated Aluminium Foils Used for Insulated Panels . Our coating include blue color, transparent color, gold color, silver color, etc.

Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam. Usual width include 1210mm, 1215mm, 1270mm, etc.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Blue Coated Aluminium Foils Used for Insulated Panels

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

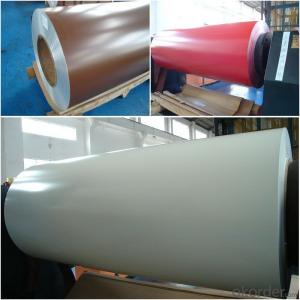

3. Blue Coated Aluminium Foils Used for Insulated Panels Images

4.Specification of Blue Coated Aluminium Foils Used for Insulated Panels

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How do aluminum coils contribute to recyclability in the construction industry?

- The inherent properties and characteristics of aluminum coils play a vital role in improving recyclability in the construction industry. To begin with, aluminum is a material that can be recycled repeatedly without losing its quality or physical properties, making aluminum coils an eco-friendly and sustainable option for construction projects. The recyclability of aluminum coils aids in reducing the environmental impact associated with the construction industry. By opting for aluminum coils, construction companies can contribute to the preservation of natural resources and the reduction of energy consumption. Recycling aluminum requires much less energy compared to producing it from raw materials, resulting in a significant decrease in greenhouse gas emissions and carbon footprint. Furthermore, the use of aluminum coils in construction simplifies the dismantling and deconstruction processes, making it easier to separate the aluminum components from other materials. This efficient separation allows for effective recycling of aluminum coils, ensuring that they can be transformed into new products or materials. Moreover, aluminum's durability and resistance to corrosion make it a suitable choice for construction applications. Its long lifespan reduces the need for frequent replacements, thereby minimizing waste generation and the consumption of raw materials. When the time comes to replace or renovate a building, the aluminum coils can be effortlessly collected, recycled, and reintroduced into the manufacturing cycle, completing the material's lifecycle. In conclusion, aluminum coils play a significant role in enhancing recyclability in the construction industry. Their high recyclability, low energy requirements for recycling, and ease of separation during deconstruction make them an environmentally friendly choice. By utilizing aluminum coils, the construction industry can promote sustainability, reduce waste generation, and conserve natural resources, ultimately leading to a greener and more circular construction sector.

- Q: What is the thermal conductivity of aluminum coils?

- The thermal conductivity of aluminum coils is high, making them efficient in transferring heat.

- Q: Can aluminum coils be recycled multiple times without losing their properties?

- Aluminum coils possess the remarkable ability to be recycled countless times while retaining their inherent characteristics. With aluminum being an exceptionally recyclable substance, the process of recycling coils entails melting the metal to its liquid state and subsequently reshaping it into fresh coils or other aluminum products. This cycle can be perpetually repeated without compromising the aluminum's quality or attributes. Remarkably, recycling aluminum consumes a mere 5% of the energy required for manufacturing new aluminum from raw materials, rendering it an environmentally conscious choice. Moreover, the properties of aluminum, including its strength, durability, and resistance to corrosion, remain unaltered throughout the recycling procedure, ensuring that the recycled coils can be employed for numerous applications just like their original counterparts. Consequently, recycling aluminum coils not only conserves valuable resources but also contributes to waste reduction and fosters sustainability.

- Q: What is the melting point of aluminum coils?

- The melting point of aluminum coils is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Im trying to make a aluminum ring. I want it to be rock hard. PLZZAnswers that work get best answer

- Dont use foil from the kitchen. Pure and simple. Get someone to machine you a piece of solid aluminum. You can't change the metallurgical properties of metal.

- Q: What are the various techniques used in the manufacturing process to create insulation for aluminum coils?

- <p>Aluminum coil insulation is produced using several methods, including lamination, extrusion, and coating. Lamination involves stacking thin sheets of aluminum with insulating material between them. Extrusion is a process where aluminum and insulation materials are pushed through a die to create a continuous profile. Coating methods apply a layer of insulating material directly onto the aluminum coil surface. These methods ensure the insulation maintains its properties under varying conditions, providing electrical isolation and protection against environmental factors.</p>

- Q: 11 g of aluminum at 200 C and 19 g of copper are dropped into 55 cm^3 of ethyl alcohol at 15 C. The temperature quickly comes to 24 C. What was the initial temperature of the copper? (answer in C) Express your answer using two significant figures.

- Quantity of heat given by aluminium = mc θ = 0.011* 913*(200 - 24) = 1767.6 J. . Quantity of heat given by copper = mc θ = 0.019* 385*(T - 24) = 7.315 T -175.56 J. . Mass of ethyl alcohol = volume * density = 0.000055 m^3 *789 = 0.043395 kg. Quantity of heat gained by ethyl = mc θ = 0.043395 * 2500*(24 - 15) = 976.3875 J heat lost.= Heat gained 1767.6 + 7.315 T -175.56 = 976.39 7.315 T = -615.65 T = -84.17 ?C This shows that copper also gains heat. ======================================...

- Q: How do you store and transport aluminum coils?

- Aluminum coils are typically stored and transported using a few different methods to ensure their safety and prevent damage. When it comes to storage, it is essential to keep the coils in a dry, clean, and well-ventilated area to avoid any moisture-related issues or corrosion. Ideally, the storage area should have a controlled temperature to prevent any extreme fluctuations that could affect the quality of the aluminum. To protect the coils from physical damage, they should be stored horizontally or vertically on a stable and level surface. It is crucial to avoid stacking them too high to prevent any potential collapse and ensure easy access for inspection or transportation purposes. Additionally, placing them on wooden pallets or racks with proper spacing between each coil can provide extra stability and protection. When it comes to transporting aluminum coils, there are several options available depending on the quantity, distance, and mode of transportation. For short distances or smaller quantities, hand trucks or forklifts can be used to move the coils onto a flatbed truck or a van. It is important to secure the coils properly using straps or bands to prevent any movement during transit. For larger quantities or longer distances, the coils can be transported using specialized coil carriers. These carriers are designed to securely hold multiple coils in an organized manner, limiting any potential damage caused by vibration or shifting during transportation. They are typically equipped with side rails and restraining bars to secure the coils in place. Regardless of the method used for transportation, it is crucial to handle the aluminum coils with care and ensure they are adequately protected. Regular inspections should be conducted before, during, and after transportation to identify any signs of damage or issues that could compromise the integrity of the coils. By following these guidelines, the storage and transportation of aluminum coils can be done efficiently and safely.

- Q: So on friday we mixed crystaline copper chloride stuffs with water to make a clear blue solution. We then put some aluminum into the solution. The solution began to heat up and there was a redish brown precipitate at the end. What caused the heat? What was boiling? How does the mass of the original aluminum and original copper chloride crystaline stuff compare with the mass of the red/brown power stuff (we strained the liquid out), and the mass of the dried up blue stuff?

- You're looking at a redox reaction. During this process, the copper ions in solution are reduced to form copper metal (visible as dust) and the aluminum metal is oxidized to form aluminum ions. This process is exothermic due to the relative electron affinities and the positions on the activity sequence such that copper has a greater affinity for electrons and is a stronger oxidizing agent. I think aluminum forms a 3+ ion and copper forms either a 1+ or a 2+ ion. Copper's molecular weight is 63g/mol and aluminums weight is 27 g/mol. You would see the weight decrease because aluminum weighs less than Copper and is replaced less frequently due to the higher charge when you figure out the ionics. Nothing was boiling.

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Aluminum coils are generally more cost-effective than other materials like copper for several reasons. To begin with, aluminum is a more abundant metal, making it cheaper to produce. Its abundance also results in more stable prices, reducing the likelihood of market fluctuations and further enhancing its cost-effectiveness. Furthermore, aluminum coils have a lower density compared to copper coils, resulting in lighter units. This lighter weight not only reduces costs for transportation and installation but also makes them easier to handle and maneuver during the manufacturing process. In addition, aluminum coils possess excellent thermal conductivity properties, enabling efficient heat transfer. This leads to more efficient cooling or heating systems, resulting in lower energy consumption and operating costs in the long run. Moreover, aluminum exhibits higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. The longer lifespan of aluminum coils reduces the need for replacements and repairs, further contributing to their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy than producing new aluminum. This aspect adds to the overall sustainability and cost-effectiveness of aluminum coils. In conclusion, considering their lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed a more cost-effective option compared to materials like copper.

Send your message to us

Wholesale Blue Coated Aluminum Foil Coil for Insulated Panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords