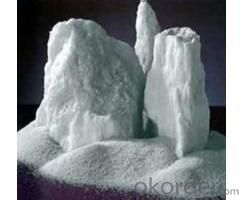

Raw Materials for Refractory:White Fused Alumina (99.2% Al2O3, 0.3% Na2O)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 25kg bag or ton bag or as your requirement. |

| Delivery Detail: | within 20 days delivery after receipt of advance payment. |

Specifications

99% high purity abrasive White fused alumina for refractory

1.White fused alumina99%

2.Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm

Products discription

1.Introduction

The main raw material of white fused alumina is high grade processed alumina, which is fused with the carbon material and scrap iron in the electic furnace under the high temperature of above 2200°C.The product is characterized by low expansion coefficient, high refractoriness, good thermal and chemical stability.

2. Grain size commonly used

Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm ,200#-0, 325#-0.

Abrasives: F24-F60.

Sandblasting abrasive:F10-F240.

Precision casting: F80-100, F100-F120.

Ceramic & electronic polishing:F240-800.

3.Physical properties of White Fused Alumina

Item | Color | Color System | Mohs Hardness | Melting Temperature(°C) | Refractory Temperature(°C) | True Density( g/cm3) | Magnetic Material |

Specification | white |

trigonal system | min10 | 2250°C | 1900°C | min3.50 | max0.003%

|

4.Chemical index of White Fused Alumina

Purpose | Specification | Chemical composition(%) | Magnetic material content(%) | ||||

Al2O3 | Na2O | SIO2 | CaO | ||||

For abrasive | F | 12#—80# | min99 | max0.6 | max0.4 | max0.003 | |

90#—150# | min98.5 | max0.003 | |||||

180#—240# | min98.2 | max0.7 | max0.4 | max0.002 | |||

For refractory | Size sand | 0—1mm | min99 | max0.5 | max0.4 | max0.003 | |

1—3mm | |||||||

3—5mm | |||||||

5—8mm | |||||||

Fine powder | 200#—0 | min98.5 | max0.5 | max0.5 | max0.003 | ||

325#—0 | |||||||

WE CAN ALSO DO NA2O:0.3% MAX IF CLIENT SPECIAL NEED.

- Q: What's the texture of refractory for the hearth of reverberatory?furnace? ?

- High alumina brick; you can use zircon brick under the temperature above 1700? ;may i use mullite bricks under the temperature from 1400 to 1700? you can use clay brick and heavy corundum brick under the temperature of below 1400 degrees, question closely: what's the usage temperature of reverberatory?furnace? < pre accuse = "qRA" > is there someone use refractory fiber?

- Q: how about the performance of aluminum silicate fire proof thermal insulation?

- aluminum silicate fire proof thermal insulation board has a good performance. it is a artificial board that separates the wood and plant fiber by mechanical and chemical methods and mixed the adhesion agent and water-proofing?agent, molding by high temperature and high press. the density of fiber. tha above information is coming from the Internet and it is just for reference.

- Q: What are included in roof thermal insulation fireproofing material?

- Aluminium foil, bubble, aluminium foil/air bubbles/fireproofing aluminium foil thermal insulation material, fireproofing bubble thermal insulation material, fire?retardant thermal insulation material, thermal insulation construction materials, aluminum foil insulation material.

- Q: whether the fire resistant level of aerated concrete building blocks can reach the grade one?

- Aerated concrete building blocks is made by calcareous materials (such as cement, lime) and siliceous material (such as sand, fly ash, slag), adding aluminum powder ingredients as filling agent, by mixing with water, casting molding, gas - expansion, raising the pre-cut, and then the high-pressure steam curing of silicate building blocks. when aerated concrete is at the temperatures below 600 ℃, the compressive strength will be increased slightly, when the temperature is at about 600 ℃, the compressive strength is close to the compressive strength at normal temperature, so the aerated concrete, as building materials, the fire performance can meet the national fireproffing safety standards level.

- Q: What are the models of bauxite with high alumina?

- China Ferrous Metal Industry Corporation released the industry standard of bauxite (YS / T78-94) in 1994. According to this standard, bauxite can be divided to sedimentary diaspore, stacked type diaspore and lateritic gibbsite. According to the chemical composition, it can be divided into nine trade marks as LK12-70, LK8-65, LK5- 60, LK3-53, LK15-60, LK11-55, LK8-50, LK7-50 and LK3-40. In addition to the provisions of chemical composition of bauxite, the standard also requires that the water of sedimentary diaspore shall not exceed 7% and water of stacked type diaspore and lateritic gibbsite shall not exceed 8%. Moreover, particle size of bauxite should be not greater than 150mm. Bauxite shall not be mixed with clay, limestone and other debris.

- Q: What's the material of electrical fire prevention board?

- Electrical fire prevention board uses the material of inorganic binders, which mainly includes water glass, gypsum, phosphate, and cement; refractory mineral fillers: alumina, asbestos powder, calcium carbonate, perlite, cornstarch and etc.; electrical fire prevention board is mainly aimed at fire protection and thermal insulation. Iron plate is electrically conductive with good thermal conductivity, which will cause the result that the equipment is not insulated and suffers larger superheating surface. Hope my answer is helpful for you.

- Q: What are the materials of class A fire resistant window?

- Fixed class A fire resistant window should be made up of steel frame, steel casement, and fireproof glass. Fire windows, made up of steel frame, steel casement, and fireproof glass, refers to window that isolate and stop the fire from spreading. Fire window is named according to the main materials of the frame and casement. Window frame is made up of steel and casement wood, vise versa. I hope it is useful.

- Q: How many types of fire-resistant material?

- 1. Acid fire-resistant material refers to one with more than 93% SiO2. It is featured by resistance to the corrosion of acidic slag ad high temperature and easy to react with alkaline molten slag. 2. Alkaline refractory material generally refers to one with magnesium oxide or magnesium oxide and calcium oxide as the main component. It has high refractoriness and strong resistance to basic slag. 3. Silicate aluminum refractory material refers to one with SiO2, Al2O3 as the main component. According to the content of Al2O, it can be divided into three categories: half siliceous (15-30% Al2O3), clay (Al2O3 30 ~ 48%), high aluminum (more than 48% of Al2O3). 4. Fused cast refractory material refers to shaped refractory products made by high temperature melting and casting.

- Q: Who knows about the B-level fireproof insulation materials?

- Organics, extruded sheet, polyphenyl board and phenolic resin. The fireproof?performance of sea capacity module (fireproof and thermal insulation material) is B1-level with the heat conductivity coefficient of only 0.028w / m · k. It is a good choice. A-level: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic aldehyde, and foam glass. B-level: Rubber and plastic, extrusion molding, polyphenyl, PEF.

Send your message to us

Raw Materials for Refractory:White Fused Alumina (99.2% Al2O3, 0.3% Na2O)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords