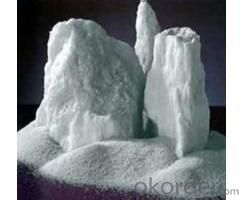

Raw Materials for Refractory - White Fused Alumina 99.5%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 25kg bag or ton bag or as your requirement. |

| Delivery Detail: | within 20 days delivery after receipt of advance payment. |

Specifications

99% high purity abrasive White fused alumina for refractory

1.White fused alumina99%

2.Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm

Products discription

1.Introduction

The main raw material of white fused alumina is high grade processed alumina, which is fused with the carbon material and scrap iron in the electic furnace under the high temperature of above 2200°C.The product is characterized by low expansion coefficient, high refractoriness, good thermal and chemical stability.

2. Grain size commonly used

Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm ,200#-0, 325#-0.

Abrasives: F24-F60.

Sandblasting abrasive:F10-F240.

Precision casting: F80-100, F100-F120.

Ceramic & electronic polishing:F240-800.

3.Physical properties of White Fused Alumina

Item | Color | Color System | Mohs Hardness | Melting Temperature(°C) | Refractory Temperature(°C) | True Density( g/cm3) | Magnetic Material |

Specification | white |

trigonal system | min10 | 2250°C | 1900°C | min3.50 | max0.003%

|

4.Chemical index of White Fused Alumina

Purpose | Specification | Chemical composition(%) | Magnetic material content(%) | ||||

Al2O3 | Na2O | SIO2 | CaO | ||||

For abrasive | F | 12#—80# | min99 | max0.6 | max0.4 | max0.003 | |

90#—150# | min98.5 | max0.003 | |||||

180#—240# | min98.2 | max0.7 | max0.4 | max0.002 | |||

For refractory | Size sand | 0—1mm | min99 | max0.5 | max0.4 | max0.003 | |

1—3mm | |||||||

3—5mm | |||||||

5—8mm | |||||||

Fine powder | 200#—0 | min98.5 | max0.5 | max0.5 | max0.003 | ||

325#—0 | |||||||

- Q: What's the feature of construction external wall fireproof and thermal inuslation matertial?

- It has properties of low heat conductivity coefficient, low density, high flexibility, fireproof and waterproof. Its heat conductivity coefficient at normal temperature is 0.018W / (K · m) . The thermal insulation property is three to eight times that of the traditional materials. And it is completely waterproof. [2] Thermal insulation lining has properties of low heat conductivity coefficient, low density, high flexibility, fireproof and waterproof. Light, generally about10-96kg / m3, 20kg / m3 or less is felt, 24-48kg / m3 is middle-hard plate, 48-96kg / m3 is hard plate, wherein 48kg / m? can be used as ceiling, with softening point being 500 ° C , thermal insulation 300 ° C. It is widely used in the United States, k =0.9. Calcium silicate thermal insulation product is developed in 1970s in China. With high compressive?strength, low heat conductivity coefficient, recycle and easily construction, it is widely used in the power system. In China, small workshop?production were the most common, then four production lines were gradually introduced from America, including instant fiber forming, dry method punched felt, which are advanced and quality, temperature endurance up to 800-1250 ° C.

- Q: What are some of the new refractories and what are their characteristics?

- Alumina, a better refractory material, is a new type of ceramic refractory, the characteristics are unclear.

- Q: What the fireproofing materialare of the refractory kettle and where they can be sold?

- Many places sell these. Nearly 10 years, can't brun when it is dry, adsorption. You can also baidu these materials. Heat transfer evenly, feldspar, clay and other raw materials with a ceramic products. Traditional casserole can not resist heat difference and also can withstand for 100 high temperature without crack. Aiming at the problem of traditional casserole, easy to crack and air permeability, people joined the spodumene on raw material, produce a high-temperature resistance casserole. It is produced after the high temperature burning makes an earthenware pot to keep the original advantages. Hebei has many places to sell these materials and is also relatively cheaper. The traditional casserole has features of not easy to transfer heat's quartz and slow cooling. Due to production technology and raw materials, it greatly improves the casserole' practicability after research and improvement.

- Q: What are the structural properties of refractory materials provided by the manufacturer of the refractories include?

- On the other hand, the turbulence is severe, and the side wall of the tundish is washed into the liquid steel and the service life of the lining of the tundish is reduced. In order to solve this problem, China 5%% honing develops a tundish anti turbulence pad, which is made of Al2O3>75% high alumina castable. Anti turbulence pad mounted casting ladle and tundish flow impact zone in the bottom of the flow out of the steel ladle nozzle casting hole center back in the anti turbulence pad repeatedly to consume the kinetic energy of the fluid flow, thereby reducing the steel flow speed, avoiding turbulence.

- Q: Does refractory belong to stone, building materials or other?

- It belongs to building materials.

- Q: What's the frequently used refractory material?

- What's the frequently used refractory material in the market? It is usually classified into four categories: Common Refractory: silica?brick, semi-silica brick, refractory fireclay block, high alumina refractory brick, magnesia brick, etc. Unshaped Refractory: repairing?mass, ramming refractory, refractory castable, plastic refractory, refractory mortar, gun-mix refractory, sling refractory, refractory coating, lightweight refractory?castables, stemming, etc. Special Refractory: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nonoxide refractories like nitride, silicide, sulfide, boride and carbide, and oxide refractories like calcium oxide, chromium hemitrioxide, alumina, magnesium oxide and beryllia, etc. Fireclay Insulating Refractory: diatomite product, asbestos product, insulation?board, etc.

- Q: What are the differences between intensive refractory busway and other busways?

- Compact busway is named according to its structure, and fire-resistant busway is named after its uses. Compact busway especially refers to busway which is closely laminated between phases and between phase and shell, and use thin insulating material to achieve the insulation result. suitable for power supply system of alternating current three-phase four-wire, three-phase five-wire system, frequency of 50 ~ 60Hz, rated voltage up to 690V, rated operational current of 250 ~ 5000A, as auxiliary equipment for mining, enterprises and high-rise buildings, and especially suitable for the transformation of workshop and old enterprises. Fire-resistant busway is composed of shell coated with fire retardant paint, bus line wrapped with fire-resistant mica tape and bracket made by refractory insulating material. Bracket has a plurality of grooves where inbedding the bus line and fixed it. There is a busway connecting box at one end of the busway and there is a bus line splitter box in the busway. Fire-resistant busway has excellent insulation properties, which can not only be used continuously in a normal environment, but also can be used in the fire environment continuously for more than one hour, suitable for high-rise buildings and important facilities, replacing the fire-resistant cables to transmit and distribute power .

- Q: What are refractory materials?

- Refractories can be divided to two categories based on the shape and three categories according to the chemical nature of acidity, neutralily and alkalinity. Alkaline refractory materials are magnesia-carbon brick, magnesia chrome brick, calcium magnesium brick and magnesia-chrome bricks. Neutural refractory mateial are high alumina brick, corundum brick and clay brick. Case-hardened refractory materials are castable, ramming mass, gunning mix, coated mix, dry vibration material, etc.

- Q: Who knows the fire endurance of B-level fireproof doors and windows?

- According to the fire endurance, fireproof doors can be divided into A-grade, B-grade and C-grade, whose fire endurance should not be less 1.2h, 0.9h and 0.6h respectively. Fire endurance of fireproof windows: A-grade fireproof windows are not less than 1.5h and B-grade fireproof windows are not less than 1h. The door leaves of A-grade and B-grade fireproof windows should be steel materials, and their glass should be composite fireproof glass whose thickness is no less than 26mm. Monolithic fireproof glass window is not B-grade fireproof window, nor A-grade fireproof glass window. It si called non-insulated fireproof window.

- Q: What kinds of refractory materials that uses a-Al2o3 powder? What are the purpose of it?

- 04La-Al2O3 powder is a alumina powder whose raw material is industrial aluminum oxide which has been calcined at high temperature. It is a good polishes for ceramics and jade, meanwhile, it is also an important raw material for high-end refractory materials. The technical indicators parameters A1023 mark A1535 chemical composition AL2O3≥ 99.92 3%, ≥ 3.10FE203≤ 0.799 Refractory calcined alumina powder (a-Al2O3) 1.2 true density (g & # 47, by fully ground powder made of different fineness .O.10 0.07 0.04NA2O≤ 0.93a-Al2O3 (%) ≥ 95 95 primary crystallization average grain (um) 2 ~ 3 3 ~ 5 average particle size (um) 40 ~ 602.6SIO2≤ 0.1 0.15B2O3≤ - 0, glass, engineering ceramics typical use electronic ceramic insulating ceramic refractory ceramic wear 3

Send your message to us

Raw Materials for Refractory - White Fused Alumina 99.5%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords