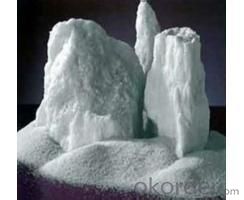

Raw Materials for Refractory:White Fused Alumina 99.2%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 25kg bag or ton bag or as your requirement. |

| Delivery Detail: | within 20 days delivery after receipt of advance payment. |

Specifications

99% high purity abrasive White fused alumina for refractory

1.White fused alumina99%

2.Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm

Products discription

1.Introduction

The main raw material of white fused alumina is high grade processed alumina, which is fused with the carbon material and scrap iron in the electic furnace under the high temperature of above 2200°C.The product is characterized by low expansion coefficient, high refractoriness, good thermal and chemical stability.

2. Grain size commonly used

Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm ,200#-0, 325#-0.

Abrasives: F24-F60.

Sandblasting abrasive:F10-F240.

Precision casting: F80-100, F100-F120.

Ceramic & electronic polishing:F240-800.

3.Physical properties of White Fused Alumina

Item | Color | Color System | Mohs Hardness | Melting Temperature(°C) | Refractory Temperature(°C) | True Density( g/cm3) | Magnetic Material |

Specification | white |

trigonal system | min10 | 2250°C | 1900°C | min3.50 | max0.003%

|

4.Chemical index of White Fused Alumina

Purpose | Specification | Chemical composition(%) | Magnetic material content(%) | ||||

Al2O3 | Na2O | SIO2 | CaO | ||||

For abrasive | F | 12#—80# | min99 | max0.6 | max0.4 | max0.003 | |

90#—150# | min98.5 | max0.003 | |||||

180#—240# | min98.2 | max0.7 | max0.4 | max0.002 | |||

For refractory | Size sand | 0—1mm | min99 | max0.5 | max0.4 | max0.003 | |

1—3mm | |||||||

3—5mm | |||||||

5—8mm | |||||||

Fine powder | 200#—0 | min98.5 | max0.5 | max0.5 | max0.003 | ||

325#—0 | |||||||

- Q: who knows the fire resistant levels of fireproofing glass?

- Fireproofing glass is a kind of special glass which can keep its integrity and thermal insulation performance in regular insulating refractory trials. and it can be divided into three classes according to its fire resistance: Class A, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. This kind of glass has the properiyies of transmittance, fireproofing ( smoke insulation, fireproofing, and keeping out thermal radiation), sound insulation, shock resistance, and it's suitable for steel and wooden fire door of building decoration, windows, varnishing, partition walldaylighting?roof,ceiling?screen,perspective floor and other construction components demading for transparency and fireproofing. Class B, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Such kind of fireproofing glasses mostly are composite fireproofing glasses and has characteristics of transmittance,fireproofing and smoke insulation. Class C, it's a kind of fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc. It's suitable for fireproofing glass partition wall, fire Windows, outside curtain wall and other places without insulation requirements. Classify from the structure,fireproofing glass can be divided into composite fireproofing glass and monolithic fireproofing glass.

- Q: What is the best refractory company?

- Chinese brick trading network, is the most authoritative third party service platform, brought together more than 3000 refractory enterprises, working day experts online to answer, to analyze and evaluate the refractory industry, at the same time, cooperation with some refractories Association, I hope to help you!

- Q: How many hours of the fire endurance time of the rock wool laminboard?

- Hello. The fire endurance now on the market is generally about two hours. The 50mm color steel sandwich version of Bo magnesium rock wool, with refractory time being five or six hours, is very good.

- Q: Does hardware construction materials contain refractory?

- refractory includes one kind of building materials. It is a special material and not commonly used.

- Q: What is the role of the vermiculite fireproof material?

- Apart from inflaming retarding, the materials covered with vermiculite has a lot of advantages including anti rust, waterproof, anticorrosive, wear-resisting, heat-resisting and the coating is armed with toughness, colorability, adhesiveness, fast-drying and luster.

- Q: Which kind of furnace hearth refractory is better?

- Coal is acidic medium, so the matched material should be acidic refractories oriented, like silica?bricks. For example, the coking coke oven and carbon furnace made of carbon are in reducing atmosphere, so they use silica bricks which have low price and good high-temperature indicators. If the part has special requirements, you can then consider other refractory on request.

- Q: What is the definition and classification of amorphous fire resistance materials?

- 9.8. brick made of refractory bone material and powder material can be used directly or after adding appropriate liquid formulation Refractory paint. Refractory slinging material 6. Prefabricated cubes, bonding agent or other additives. fire-resistance sparying material compround additives. Refractory pressed into the material, binder. Refractory ramming material 3, The material is a new fire proof material without calcination Heavy aggregate and lightweight aggregate: Inorganic binding agent and organic bond, its fire resistance is not less than 1580. Refractory castables 2 mouldable refractory Classification according to the type of bonding agent: 1. Classification according to refractory aggregate. According to the production and construction method, refractory mud or refractory mire, with a certain proportion of the mixture

- Q: Does refractory belong to metallurgical auxiliary materials?

- Refractory is widely used in industrial circle, such as metallurgy, chemical industry, petroleum, mechanical manufacturing, silicate and power, and its coonsumption is the maximum in metallurgy, accounting for 50% to 60% in total output. In order to improve slag-corrosion resistance of furnace lining, usually choose carbon-containing refractory. Refractory of various furnace lining are respectively: For the body, it is clay brick; as for the lower part, bosh and middle, it is SiC brick; for furnace bottom, it is carbon brick. Lattice brick is an important refractory product used in air heating furnace and regenerative chamber. Refractory is widely used in metallurgy. In order to improve slag-corrosion resistance of lining. Central line in tuyere and hearth are high-alumina brick. Refractory consumption is the maximum in metallurgy, accounting for 50% to 60% in total output. For the bosh and middle, it is SiC brick. In order to improve its thermal storage capacity: The furnace stack is clay brick. It is defined as refractory where the physical and chemical properties allows its use in high temperature environments; The lower furnace body

- Q: The manufacturing technique of refractory material

- The major components of alkaline refractory material include magnesium oxide and calcium oxide. The commonly used alkaline refractory material is magnesia bricks. The magnesia bricks with 80%~85% magnesium oxide has good resistance to basic slag and slag and higher refractoriness than clay bricks and silica bricks. It is mainly used in open hearth, oxygen blowing of converter, electric furnace and smelting non-ferrous metal equipment and other high temperature equipment. Refractory materials applied on special occasions include high temperature oxide refractory materials such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, etc., refractory compounds such as carbide, nitride, boride, silicide and sulfide, etc., and high temperature composite materials, including metal ceramics, high temperature inorganic coating and fiber reinforced ceramics, etc. Consult and find reference for efractory materials production equipment, go to http://hi.baidu.

- Q: What kind of refractory material should be used for common boiler?

- Build by using clay refractory mortar. Common clay brick is used as combustion layer. Xindeyuan Refractory Material, red?brick is used as external wall. Light clay brick is used as thermal insulation layer, thank you.

Send your message to us

Raw Materials for Refractory:White Fused Alumina 99.2%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords