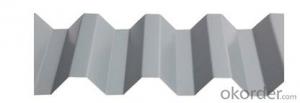

WHITE COLOR CORRUGATED GALVANIZED SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

WHITE COLOR CORRUGATED GALVANIZED SHEET

1.standard:ASTM BS DIN JIS GB

2.grade:SGCC/DX51D

3.zinc coating:Z40-275g/m2

4.package:export standard package or as per the buyers' requirement

5.Application:mainly used in the field of roof ,outer wall and cabinet,automotive manufacturing, electrical products, locomotives, aviation, precision instrument, canned food, ect.

6.Product features:

(1) good durability, and can be used longer than galvanized steel ;

(2) has good heat resistance, and compared with galvanized steel,under high temperature it does not discolor easily;

(3) has good heat reflecting

(4) have silvery white luxuriant surface;

(5) has machining capability and spraying performance similar to galvanized steel ;

(6) good weldability.

(7)thickness: 0.18mm to 1.2mm

Features for corrugated roofing sheet

1) Roll formed by roll forming machines, the thickness and color can be different

2) Easy installation

3) High strength

4) More economic (low cost)

5) They are widely use as the wall or roof of factory, warehouse, garage,

exhibition center and cinema

6) Raw materials: Cold-rolled steel, galvanized steel, galvanized pre-painted

sheet and aluminum sheet

7) A fluted profile makes it suitable for many applications where flat sheet would

not normally be considered. The longitudinal flutes provide rigidity along the

length of the sheet while retaining full flexibility across the width...

- Q: How are steel coils coated for specific applications?

- Steel coils are coated for specific applications through a process called coil coating. This involves applying a protective layer of paint, polymer, or other coatings onto the steel coils using methods like roll coating or spray coating. The coating is carefully selected based on the desired properties such as corrosion resistance, durability, or aesthetic appeal required for the specific application.

- Q: It seems that steel would be stonger and more stable than wood, fire resistant, and better for the environment, so why are most homes wood-framed rather than steel-framed?

- Because it's always been done that way. Never underestimate inertia when asking why new materials/techniques are not adopted. Besides, the cost does not give steel a clear advantage. You can drive a nail anywhere into a stud. With steel, you have to drill your holes precisely.

- Q: How are steel coils processed for edge trimming or conditioning?

- Steel coils are processed for edge trimming or conditioning through a series of steps. First, the steel coils are unwound and fed into a machine that trims the edges to remove any irregularities or imperfections. This process helps ensure that the edges of the steel coils are straight and smooth. After edge trimming, the coils may undergo further conditioning processes such as leveling, slitting, or recoiling, depending on the specific requirements of the end product. These processes help to refine the steel coils and prepare them for various applications in industries such as automotive, construction, or manufacturing.

- Q: How are steel coils used in the production of wire products?

- Wire products rely heavily on steel coils, which are indispensable in their production. These coils, typically crafted from high-quality steel, serve as raw materials in wire drawing processes. Wire drawing, a manufacturing technique, diminishes the coil's diameter, converting it into diverse wire products. The initial step involves the placement of a steel coil onto a wire drawing machine. Subsequently, the machine pulls the coil through a sequence of progressively smaller dies. Each die the coil passes through reduces the wire's diameter, resulting in a more slender and elongated wire strand. This process can be repeated multiple times until the desired wire thickness is achieved. Once the wire is drawn, it can undergo further processing to create an array of wire products, including fencing, nails, screws, springs, and electrical wires. The wire can be cut into specific lengths, bent, or shaped to suit its intended purpose. Moreover, it can undergo treatments like galvanizing or coating to enhance its durability and resistance to corrosion. Steel coils offer numerous advantages in wire product manufacturing. Firstly, they provide a consistent and uniform material, ensuring the resulting wire products possess consistent quality and performance. Secondly, steel coils are easily transportable and can be stored efficiently, making them a cost-effective choice for manufacturers. Lastly, the versatility of steel enables the production of wire products with varying tensile strengths and properties to meet specific industry requirements. To summarize, steel coils play an essential role in wire product manufacturing. They serve as the primary raw material in wire drawing processes, where they undergo a series of reduction steps to be transformed into diverse wire products. These wire products find applications across various industries, solidifying the indispensability of steel coils in the manufacturing sector.

- Q: Can anyone tell me what that means. I have seen it on knife blades an such. I am assuming it's a formula for the strength of the metal. who does that scale work, and please keep it simple.

- 440 is an AISI (American Iron and Steel Institute) material specification. It specifies the precise quantities of carbon and other elements present in the alloy. Here are the constituents of AISI 440 steel: Carbon - 0.6 to 0.75% Chromium - 16 to 18% Manganese - less than 1% Molybdenum - less than 0.75% Phosphorus - less than 0.04% Silicon - less than 1% Sulfur - less than 0.03% Iron makes up the remainder. AISI 440 is a heat-treatable, precipitation-hardening stainless steel.

- Q: I was watching a documentary on the samurai vs the European knight. It said that the when Japan was being invaded by the (cant remember) they needed a new weapon. The enemies armor made iron swords useless. While steel swords broke when in combat. So to combat this the Japanese made a hybrid sword. They used a special mold that made the swords back iron while the part that makes contact with the enemy was steel. Also the sword was curved so it increased its armor and cutting power. This revolutionary design made the the sword stronger. The iron back made it not break while the steel edge made it cut through the enemies armor. I want to know how iron is stronger than steel, and how steel can cut better than iron.

- Firstly Iron is not stronger than Steel. You must understand that steel is made with iron. Steel is iron with carbon infused into the crystal lattice; thus making it stronger. Iron was used as the backing because it is more ductile and resilient than steel because steel is stronger and more brittle. So on this basis steel is stronger and better to hit the armor first with more cutting power because it wont yield to softer materials, and iron was suited for the backing because it would allow it to bend as pressure is being applied, but without braking.

- Q: How do steel coils contribute to the manufacturing of electrical appliances?

- Steel coils are essential components in the manufacturing of electrical appliances as they are used to create the core of transformers and electromagnets. These coils, made from steel, provide the necessary magnetic field required for the functioning of electrical appliances such as refrigerators, televisions, and washing machines.

- Q: The Iron and Steel Corporation of Great Britain (1949) or Iron and Steel Bill was introduced in 1949 during the Labour post-war Government.What was it introduced for?

- It was a holding company that originally had 107 companies who manufactured iron or steel products in Great Britain.

- Q: Are they made using the same processes, or is tempered steel made without the quenching process?

- No. Not quite. The term 'Hardened steel' is often used to refer to 'Heat treated steel'. There are two separate steps in heat treatment. First the red hot steel is 'quenched' (rapidly cooled). This yields maximum hardness ,but the steel may be too brittle for the intended purpose. The next stage, 'tempering' is heating to a limited temperature, and slow cooling. This reduces the hardness somewhat, depending on the re-heat temperature, but restores some of the toughness lost in the first stage.

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- A steel frame would weigh at most 2 pounds more than an aluminum frame. That would be comparing a less expensive steel frame to a really good aluminum frame. However if you are talking about comparable prices the weight difference would be much less, about 1 pound

Send your message to us

WHITE COLOR CORRUGATED GALVANIZED SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords