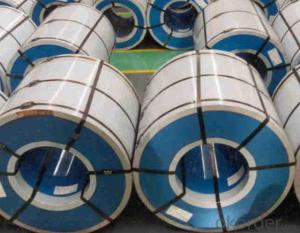

Wear resistant steel plate coil,/color steel coil/prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,GB,JIS | Grade: | DX51D | Thickness: | 0.13mm-0.8mm,0.13-0.7mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | CNBM | Model Number: | HUAYE224 |

| Type: | Steel Coil | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Constuction, Furniture, transport, electrical equipment,ect. | Special Use: | Wear Resistant Steel | Width: | 800mm-1250mm,1000mm, 1200mm,1250mm |

| Length: | As the width and thickness | Color: | Sea blue, white grey, crimson, green or as RAL | Zinc coating: | 40-100gsm |

| Coil Weight: | 3-6 Tons | Coil ID: | 508mm | Back coating thickness: | 5-7um |

| Top coating thickness: | 13-20um |

Packaging & Delivery

| Packaging Detail: | seaworthy expot package |

| Delivery Detail: | 15-20 days after receiving deposit by T/T |

Specifications

Wear resistant steel plate

1.Competitive price and High quality

2.Anti-corrosion

3.Width:800-1250mm

4.Thickness:0.13mm-0.7m

Business Products

Color coated galvanized steel coil (prepainted galvanized steel coil)

Shandong Huaye colour steel coil supplier

Wear resistant steel plate

PPGI sheet metal steel gauge

Galvanized steel coil (znc coating steel coil)

Galvalume steel coil (alu-zinc coating steel coil)

Cold rolled steel coil

Color coated galvanized steel coil

Characteristic

Thickness: 0.13mm-0.8mm

Width: 914mm-1250mm

Zinc coating: 40-150gsm

Color: Red, green, orange, white, blue, or as RAL code

Coating thickness: top: 13-20um; back: 5-7 um

Coil ID: 508mm10mm

Coil weight: 3-6 metric tons

Base material: Galvanized steel coil, galvalume steel coil, cold rolled coil, ect.

Packing: 4 eye bands and 4 circumferential bands in steel, galvanied metal fluted rings on inner and outer edges, galvanized

metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

Port of loading: Qingdao, Tianjin, Shanghai and so on

- Q: How are steel coils inspected for coil weight accuracy?

- Steel coils are inspected for coil weight accuracy using weighing scales or load cells. The coils are placed on the scales or load cells, and the weight is measured to ensure it matches the specified weight range.

- Q: What are the common methods of testing the durability of steel coils?

- Common methods of testing the durability of steel coils include tension tests, impact tests, bending tests, hardness tests, and corrosion tests.

- Q: What are the different types of steel coil surface treatments for indoor applications?

- The different types of steel coil surface treatments for indoor applications include hot-dip galvanizing, electro-galvanizing, and organic coating.

- Q: Can steel coils be galvanized?

- Yes, steel coils can be galvanized. Galvanizing is a process of applying a protective zinc coating to steel to prevent corrosion and increase its durability. Steel coils are commonly galvanized to enhance their resistance to rust and other forms of corrosion.

- Q: Can steel coils be returned if they are damaged?

- Yes, steel coils can be returned if they are damaged. However, the return policy may vary depending on the supplier or manufacturer. It is important to check the terms and conditions of purchase, including any warranty or guarantee, to understand the specific guidelines for returning damaged steel coils.

- Q: What are the different steel coil specifications?

- There are various steel coil specifications available, including dimensions (thickness, width, and length), chemical composition, mechanical properties (such as tensile strength and yield strength), surface finish, and coating options. These specifications vary depending on the specific application and industry requirements.

- Q: How are steel coils used in the production of steel containers?

- Steel coils are an essential component in the production of steel containers. These coils, made from flat-rolled steel, are used to create the main body of the container. Firstly, the steel coils are unwound and fed into a rolling mill, where they undergo a series of processes to shape and form the steel. This includes heating the coils to a specific temperature to make them more malleable and easier to work with. The hot coils are then passed through a series of rollers that gradually reduce their thickness and lengthen them to the desired size. This process is known as hot rolling. Once the steel coils have been rolled to the required thickness, they are then cooled and cut into sheets. These sheets are then further processed to remove any imperfections or irregularities, ensuring a smooth and uniform surface. This is done through processes such as pickling, where the sheets are treated with acid to remove any scale or rust, and cold rolling, where the sheets are passed through rollers at room temperature to achieve the desired thickness and surface finish. After the sheets have been cleaned and smoothed, they are then formed into the shape of the container. This is typically done through a process called stamping, where the steel sheets are pressed into a mold using a hydraulic press. The mold determines the shape and size of the container, and the steel sheets are pressed against it with immense force, resulting in the desired container shape. Once the containers have been formed, they undergo various finishing processes such as welding, painting, and coating to enhance their durability, appearance, and resistance to corrosion. These final touches ensure that the steel containers are of high quality and meet the required standards for their intended use. In summary, steel coils play a crucial role in the production of steel containers by providing the raw material from which the containers are formed. Through a series of processes, the steel coils are shaped, cut, and formed into sheets, which are then further processed and transformed into the desired container shape. The result is a durable and reliable steel container that can be used for various applications across industries.

- Q: What are the different grades of steel used in coils?

- There are several different grades of steel used in coils, including low carbon steel, high carbon steel, stainless steel, and alloy steel. Each grade has its own unique properties and is used for specific applications based on factors such as strength, durability, corrosion resistance, and formability.

- Q: What are the common methods of inspecting steel coils for defects?

- Inspecting steel coils for defects involves several commonly used methods. These methods encompass visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. Visual inspection, the most basic method, entails physically examining the steel coil's surface for noticeable defects like cracks, dents, or irregularities. Typically, this initial step in the inspection process promptly identifies any obvious defects. Ultrasonic testing, a more advanced method, employs high-frequency sound waves to detect defects within the steel coil. Ultrasonic waves are transmitted into the coil via a probe, and any internal flaws or defects reflect the waves back to the probe. This method effectively identifies defects such as voids, cracks, or inclusions. Magnetic particle inspection is another commonly utilized method. It involves magnetizing the coil and applying iron particles to the surface. Defects or cracks disrupt the magnetic field, attracting the iron particles and making them visible. This method is particularly effective for surface cracks or defects. Eddy current testing is a non-destructive method utilizing electromagnetic induction to detect defects in the steel coil. By generating an alternating magnetic field using a probe, any changes in the material's electrical conductivity or magnetic permeability due to defects generate eddy currents. These eddy currents can be measured and analyzed to identify defects like cracks, voids, or changes in material properties. In summary, these common methods offer varying levels of accuracy and sensitivity in inspecting steel coils for defects, ensuring their quality and integrity. The choice of method depends on factors such as the type and size of defects to be detected, the required level of inspection accuracy, and the time and cost limitations of the inspection process.

- Q: How are steel coils used in the production of industrial tanks?

- Steel coils are used in the production of industrial tanks as they are rolled and formed into the desired shape to create the tank's structure. The coils provide the necessary strength and durability required to withstand the pressure and weight of the tank's contents.

Send your message to us

Wear resistant steel plate coil,/color steel coil/prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords