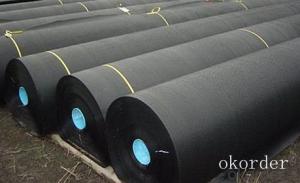

Non Woven Geotextile Drainage Fabric Waterproofing Environmental Engineering HDPE Liner

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Thickness:

1mm-3mm

Length:

50-200m as customers' request

Width:

4m~9m

Standard:

ISO, CE

Feature:

Chemical Resistant

Surface:

Textured Surface

Product name:

hdpe geomembrane manufacturers

Keyword:

hdpe geomembrane manufacturers

Application

1. high quality hdpe geomembrane use in agriculture

1. high quality hdpe geomembrane use in agriculture farm

3. high quality hdpe geomembrane use in shrimp ponds orLotus

Technical specifications of HDPE geomembrane:

a) Density ≥ 0.94g/m2

b) Tensile Strength ≥25Mpa

c) Elongation at Break ≥ 550%

d) Right-angled Tear ≥ 110N/mm

e.)Puncture Strength ≥ 550N

Applicable to river dams, tunnels, drainage bank seepage, metallurgy and chemical industry pollution prevention, construction, transportation, environmental protection works.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the specifications for geotextiles in railway projects?

- The specifications for geotextiles in railway projects generally include requirements for strength, durability, permeability, and filtration. These geotextiles should have sufficient tensile strength to withstand the dynamic loads imposed by trains and maintain their integrity over time. They should also be resistant to degradation caused by UV exposure, chemical exposure, and biological factors. The permeability of geotextiles is crucial to ensure proper drainage and prevent water accumulation, which can lead to instability. Additionally, the geotextiles should possess excellent filtration properties to prevent the migration of fine particles and maintain the stability of the railway subgrade.

- Q: Shield Machine Tool material which is the hardest

- If I remember correctly, it should be chromium carbide material

- Q: Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Q: Can geotextiles be used in the protection of retaining walls?

- Yes, geotextiles can be used in the protection of retaining walls. Geotextiles are permeable fabrics that can provide reinforcement and stabilization to the soil behind the retaining wall. They can help prevent erosion, reduce water pressure, and improve the overall stability and longevity of the retaining wall.

- Q: What are the factors to consider when designing geotextile-reinforced walls?

- When designing geotextile-reinforced walls, several factors need to be considered. 1. Soil characteristics: It is important to assess the soil properties such as its strength, permeability, and compaction. This information helps determine the appropriate geotextile material and reinforcement spacing required for stability. 2. Wall height and slope: The height and slope of the wall impact the design of the geotextile-reinforced structure. Steeper slopes may require additional reinforcement layers or geogrids for increased stability. 3. Loadings and surcharges: The anticipated loads and surcharges on the wall, such as traffic loads or nearby structures, should be considered to determine the necessary strength and stability requirements for the geotextile-reinforced wall. 4. Water and drainage: The presence of groundwater or surface water must be evaluated as it can affect the stability and durability of the wall. Proper drainage systems need to be incorporated to prevent water buildup behind the wall. 5. Environmental considerations: The potential impact of the geotextile-reinforced wall on the surrounding environment should be assessed. This includes factors like vegetation, wildlife habitats, and erosion control measures. 6. Construction methods and access: The availability of construction equipment and access to the site will influence the choice of geotextile materials and construction techniques. Considering these factors ensures the geotextile-reinforced wall is designed to withstand the required loads, maintain stability, and have long-term durability.

- Q: What are the advantages of using geotextiles in green space development?

- There are several advantages to using geotextiles in green space development. Firstly, geotextiles can help with soil erosion control by stabilizing the soil and preventing its displacement. This is particularly important in areas with slopes or where heavy rainfall is common. Secondly, geotextiles can improve soil drainage, allowing excess water to pass through while retaining the necessary moisture for plant growth. This helps prevent waterlogging and promotes healthier root systems. Additionally, geotextiles act as a barrier, preventing weed growth and reducing the need for chemical herbicides. Finally, geotextiles can enhance the longevity of green spaces by providing a protective layer between the soil and other materials, such as gravel or sand, which can prevent contamination and preserve the overall quality of the space.

- Q: How do geotextiles improve the performance of sports fields?

- Geotextiles improve the performance of sports fields by providing stability, drainage, and reduced soil erosion. They act as a barrier between the soil and the grass, preventing the mixing of materials and maintaining a consistent playing surface. Additionally, geotextiles enhance water drainage, preventing waterlogging and ensuring a drier field, which improves playability and reduces the risk of injuries. The use of geotextiles also minimizes soil erosion, preserving the field's integrity and reducing the need for frequent maintenance.

- Q: What are the different factors to consider when selecting a geotextile?

- When selecting a geotextile, several factors need to be considered. These include the project's specific requirements, such as the expected load and traffic conditions, the soil type and composition, the desired lifespan of the geotextile, and any environmental considerations. Additionally, factors such as the geotextile's strength, permeability, and compatibility with other materials used in the project should also be taken into account.

- Q: Unit of the quality of 400 geotextile piercing strong is generally how much? Hurry more

- First, geotextile polyester staple fiber geotextile (PET) and polyester filament geotextile two. Two kinds of geotextile anti-puncture strong (should be CBR burst strong) different. Polyester staple geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester staple geotextile CBR burst strength ≥ 2.1KN. Polyester filament geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester filament geotextile CBR burst strength ≥ 39KN. 400g GB polyester staple geotextile longitudinal and horizontal tear strength ≥ 0.33KN, 400g GB polyester filament geotextile longitudinal and horizontal tear strength ≥ 0.56KN.

- Q: Can geotextiles be used in groundwater protection systems?

- Yes, geotextiles can be used in groundwater protection systems. Geotextiles are permeable fabrics that can effectively filter and separate soil particles and other materials, preventing their migration into groundwater. They can be used as liners, barriers, or filters in various groundwater protection systems, such as landfills, ponds, and stormwater management systems, to enhance water quality and prevent contamination.

Send your message to us

Non Woven Geotextile Drainage Fabric Waterproofing Environmental Engineering HDPE Liner

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords