Waterproof Non-woven Aramid Fabric with PTFE Film/Moisture Barrier Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

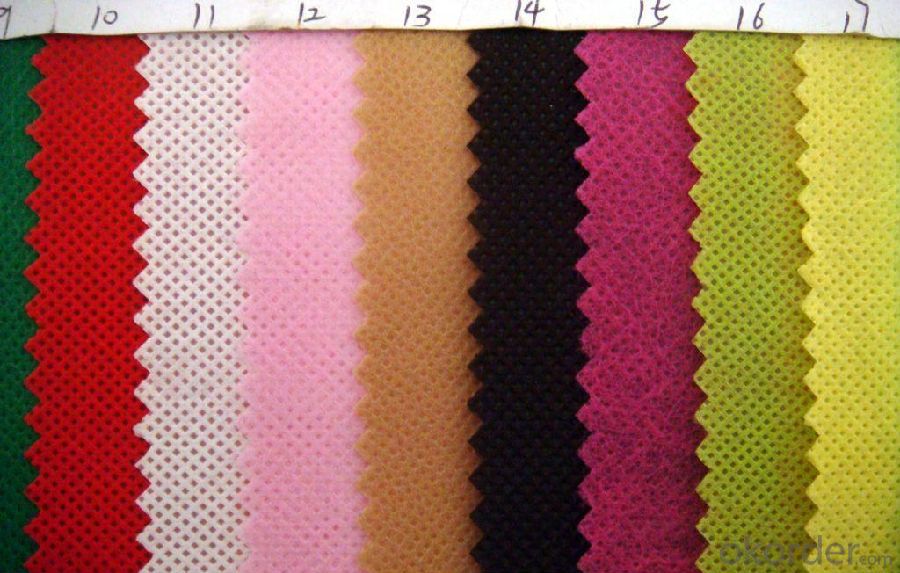

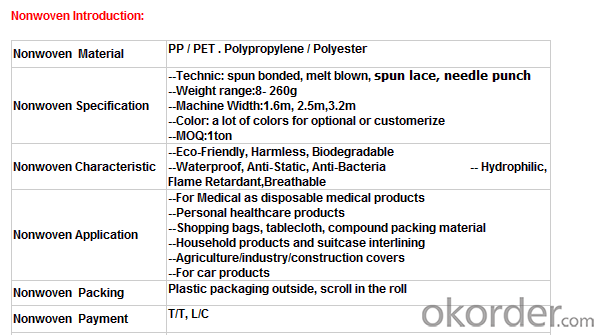

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Textile printing and dyeing process which

- Dyeing long car is divided into two parts, before the car dyeing, after the car fixing color. Dyeing method according to the choice of different varieties of dyes are different, dyes are generally active, Shihlin, vulcanization, paint. They have their own advantages and disadvantages, under normal circumstances to see the color requirements, and can not replace each other.

- Q: Are hats a class of textile and apparel products?

- All year round seems to generally only winter hat, hat should belong to the textile and apparel products bar. Jewelery is available all year round.

- Q: What are the types of textiles that are different?

- Use is not the same, it has the function is not the same. Such as clothing textiles, may be cotton, elastic, CVC, modal, silk more; decoration may be numb and so on; industrial use, there are waterproof, etc.

- Q: Cotton chemical fiber textile, hemp textile, wool textile, silk silk textile industry, the difference between the four

- From the 1998 cotton management system reform, to fully liberalize the cotton purchase and marketing market in 2004, China's cotton industry has entered a new stage of development.

- Q: Processing of textiles, processed products were detected formaldehyde exceeded, how to deal with

- Direct contact with the skin of textiles, not more than 75PPM; 3, non-direct contact with skin textiles, not more than 300PPM;

- Q: What is the number of raw materials for textile enterprises?

- General varieties are used, PVA, modified starch and other main pulp, plus propylene and wax tablets and other additives,

- Q: China textile products do not how points? What kind of?

- Scale, distribution tends to focus. Jiangsu Province as a full range of fiber Dasheng fabric Dasheng clothing province, clothing annual output, sales, profits are among the forefront of the country

- Q: Clothing and processing and processing into what auxiliaries

- Need to waterproof, plus waterproof finishing agent, the need to increase the soft, softening agent and so on. Finally processed into clothes, this part requires a relatively small amount of additives

- Q: Do you need to do environmental protection for dry textile processing?

- Individual industrial and commercial business license is only one, but the composition is divided into two types of family management and personal business

- Q: Mechanical characteristics of textile machinery

- The continuity of textile machinery is subject to the process. For example: spinning 20.8 ~ 27.8 cotton yarn, from cotton to spinning the total draw ratio of 13900 ~ 19000 times. The process needs to go through the cleaning of cotton, carding, parallel, roving, spun yarn and other processes, it must be distributed in the process of the corresponding equipment to complete.

Send your message to us

Waterproof Non-woven Aramid Fabric with PTFE Film/Moisture Barrier Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches