Wholesale PP Non Woven Fabric For Non Woven Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

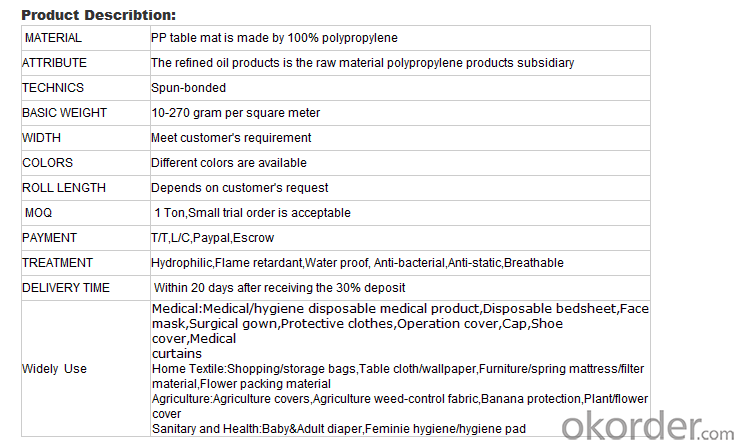

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Textile industry after finishing what pollution, especially air pollution

- Big talk about the air side of the textile enterprises are usually in the air nitrogen and sulfur oxides will be excessive even if you can escape the environmental monitoring brigade check is usually no night to steal because the air pollution handling costs are too large and too much and I can clearly say Just can smell the odor can be concluded that serious pollution

- Q: What are the test tests for the color fastness of textiles?

- 13, resistant to non-chlorine color fastness 14, resistance to chlorine color fastness 15, acid color fastness 16, alkali color fastness 17, water-resistant color fastness 18, resistance to organic solvent friction color fastness

- Q: What is the textile project

- Textile engineering, including textile trade and textile and garment in two directions. Cultivate students with the basic theory and technology of textile engineering to meet the needs of textile and garment trade and production market

- Q: Textile raw materials of mineral fiber

- A natural or synthetic polymer compounds as raw materials by chemical spinning made of fiber. Can be divided into man-made fibers, synthetic fibers, inorganic fibers

- Q: What is the "gold and silver wire" used in the textile industry?

- Gold and silver: that is, the physical method will be coated with color PET polyester film cut into very fine wire. Through the polyester film or nylon film plating method to make the surface coated with a layer of aluminum or silver, and then according to the textile needs to be processed into different width of the wire

- Q: What is the meaning of the number of yarns used in cotton textiles?

- The fineness of the yarn (in English): refers to a pound (454 grams) of heavy cotton yarn in the provisions of moisture regain, there are several 840 yards (1 yards = 0.941 meters) long, that is, a few miles of yarn, As "a few yarn", the unit with "S" said.

- Q: The meaning of the following terms in the textile industry: fabric, processing number, genuine number.

- Shrink the fabric mainly refers to cotton, linen, silk, such as natural fabrics. The shrinkage rate is related to its own fiber, but also to its tightness.

- Q: What are the knowledge and abilities of the Merchants in the textile industry?

- You need to know that the list is a follow-up clues, but, in order to press, according to the amount, according to the quality of completion, will encounter a lot of problems, such as: duration arrangements, the number of inconsistencies and so on

- Q: How to do the textile warehouse damp

- In the entire processing of the textile mill process, whether it is on the production workshop, or the storage warehouse, are the need for strict humidity control! Only in the most appropriate humidity environment for the production of textile storage, in order to ensure the quality of textiles.

- Q: What is the use of polyurethane TPU hot melt adhesives in textiles?

- Adhesive interlining is made on the surface of the fabric. When used, the adhesive lining is cut into the desired shape and size, and the side coated with the hot melt adhesive is thermocompression bonded to the back of the other fabric material (fabric). It lined in the clothing layer, as the backbone of clothing, simplifying the garment processing technology and time, so that clothing with light, beautiful, comfortable, security type, washable, durable and many other effects.

Send your message to us

Wholesale PP Non Woven Fabric For Non Woven Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches