polyester non woven fabric,breathable nonwoven fabric, hydrophobic nonwoven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

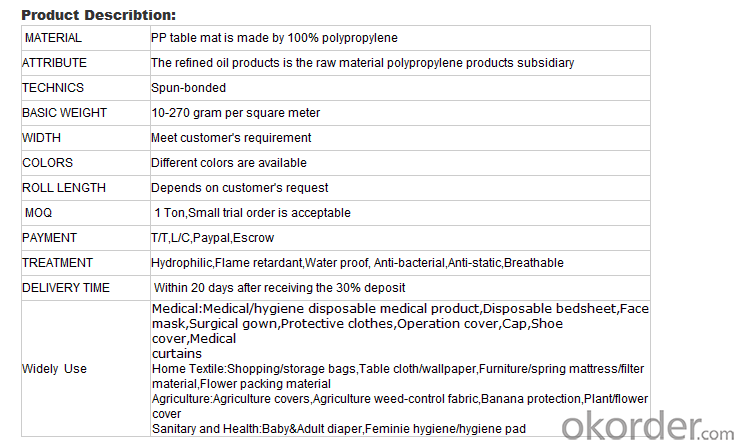

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What are the test tests for the color fastness of textiles?

- 13, resistant to non-chlorine color fastness 14, resistance to chlorine color fastness 15, acid color fastness 16, alkali color fastness 17, water-resistant color fastness 18, resistance to organic solvent friction color fastness

- Q: What are the processes of dyeing and finishing of textiles?

- Different raw materials processing process is not exactly the same, the specific operation of specific raw materials.

- Q: What is the "gold and silver wire" used in the textile industry?

- Rhitherigma compositions. Refithers. Find Results Avithers.ithers. Rhithericals.s.ithers. Rhithergs.ithers. Rhithergs.ithers. Rhithergs.ithers. Rhithergs.itheromenigma Rhithers. Rhithergs.ithers. Rhithergs.itheromenigma Rhithers. Rhithergs.ithers. Rhithergs.omeniculates Rhithergs.ithers. Rhithergs.omeniculates Rhithergitherigmaither Rhitherd Rh to Rhomenacheither Rhomenigma Rhitheric roundsy Avg -

- Q: Classification of textile materials

- The yarn is composed of fiber, with pure spinning yarn, blended yarn, with yarn distribution; according to the distribution of mixed fiber, there are evenly mixed yarn, change the mixed yarn, combination or composite yarn points

- Q: What is the amount of alkali in the textile mill

- Silk is the softest and most breathable raw material for all textile materials. The polyester is a synthetic fiber, non-hygroscopic, airtight, feel rough

- Q: Performance requirements for textile fibers

- The abrasion resistance of the fiber is closely related to the fastness of its textile products. The wear and tear of the pros and cons is the performance of clothing with fabric is an important indicator.

- Q: Classification of antimicrobial textiles and their characteristics

- Chemical fiber products, the characteristics of the most suitable adhesive to add antibacterial agents, hollow phase change fiber is also more suitable, there is no particularly good product.

- Q: Do you need to do environmental protection for dry textile processing?

- Do the self-employed business license procedures simple, low cost, only 23 pieces. The information required to do the business license is: the original ID card and

- Q: From the yarn to the finished textile fabric production process is how

- Is the famous American chemist Carothers and his research team invented. The main varieties of nylon are nylon 6 and nylon 66, accounting for the absolute dominant, followed by nylon 11, nylon 12, nylon 610, nylon 612, in addition to nylon 1010, nylon 46, nylon 7, nylon 9, nylon 13, Varieties are nylon 6I, nylon 9T and special nylon MXD6 (barrier resin) and so on

- Q: What is the use of polyurethane TPU hot melt adhesives in textiles?

- Carpet rubber adhesive with the basic material for the ethylene and other olefinic monomer copolymer, such as ethylene - vinyl acetate copolymer, ethylene acrylate copolymer. The vast majority of cases are the use of ethylene. Vinyl acetate copolymer (EvA).

Send your message to us

polyester non woven fabric,breathable nonwoven fabric, hydrophobic nonwoven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords