pp non woven fabric manufacturer in china for shopping bags

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

pp non woven fabric for shipping bags/garment packing and so on

1)thickness:30-200gsm

2)size:160-320cm

3)color:any color is possible

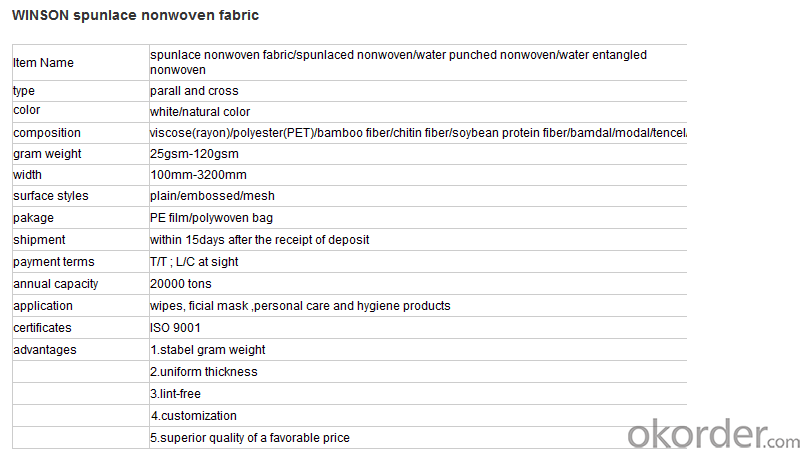

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

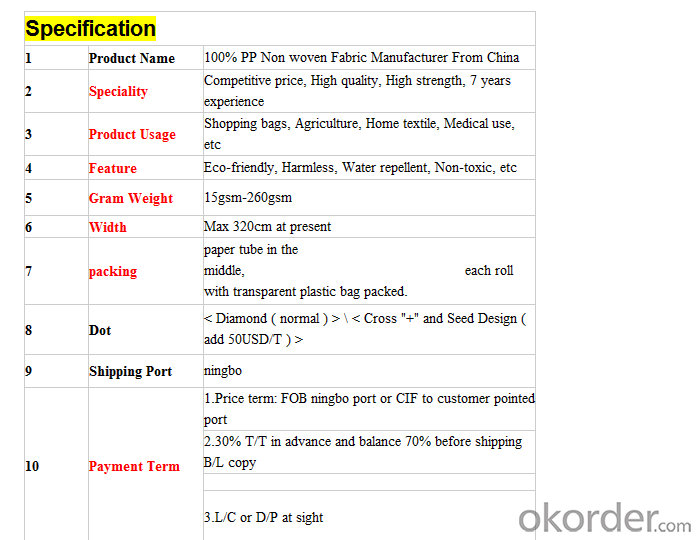

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What is the textile project

- Graduates of textile engineering can generally work in the technical and business management departments of textile enterprises in the process design, production management, product development and other work, to the business and foreign trade and other departments engaged in business management and professional foreign trade work, but also in scientific research units, Textile schools engaged in scientific research, teaching work.

- Q: What are the processes of dyeing and finishing of textiles?

- Different raw materials processing process is not exactly the same, the specific operation of specific raw materials.

- Q: Differences between textile mills and garment factories

- After the carding, and lines, twisting, roving, spun yarn, winding, warping, weft, weaving, finishing and other long process made of gray cloth, and then sent to the printing and dyeing plant dyeing and finishing,

- Q: Classification of antimicrobial textiles and their characteristics

- Coating is mainly used for water-proof breathable and other outdoor products, because the coating surface is not suitable for skin wear. What you said might be the effect of adding auxiliaries to the cotton fabric finishing.

- Q: Is the textile processing and sales tax rate the same?

- Tax rate refers to the value-added tax taxpayers should be included in the current value-added tax accounted for the current taxable sales revenue example. For small-scale taxpayers, the tax rate is the collection rate: 3%

- Q: China is now optimistic about which one of the textile industry

- Special decorative textiles industry multi-functional high-level tent materials, automotive lightweight cover and interior materials, membrane structure materials and other special decorative textiles processing technology and industrial applications.

- Q: DTY FDY POY What are the textile raw materials?

- DTY: Stretch deformation wire, full name: DRAW TEXTURED YARN. Is the use of POY to do the original wire, stretching and false twist deformation made of processing. Often have a certain degree of flexibility and contraction. (Generally divided into network and no network of silk, the network means the network node

- Q: Do you need to do environmental protection for dry textile processing?

- Individual industrial and commercial business license is only one, but the composition is divided into two types of family management and personal business

- Q: What is the earliest textile raw material?

- Textiles of different periods are one of the measures that measure the progress of mankind and civilization

- Q: What is the use of polyurethane TPU hot melt adhesives in textiles?

- Adhesive interlining is made on the surface of the fabric. When used, the adhesive lining is cut into the desired shape and size, and the side coated with the hot melt adhesive is thermocompression bonded to the back of the other fabric material (fabric). It lined in the clothing layer, as the backbone of clothing, simplifying the garment processing technology and time, so that clothing with light, beautiful, comfortable, security type, washable, durable and many other effects.

Send your message to us

pp non woven fabric manufacturer in china for shopping bags

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches