Waterproof Enviromently-Friendly WPC Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

3> Why choose WPC decking?

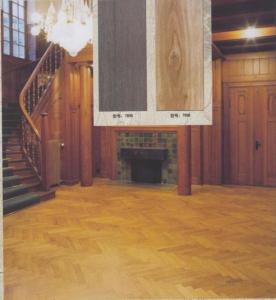

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

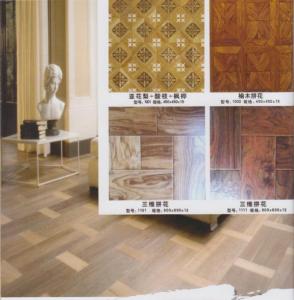

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

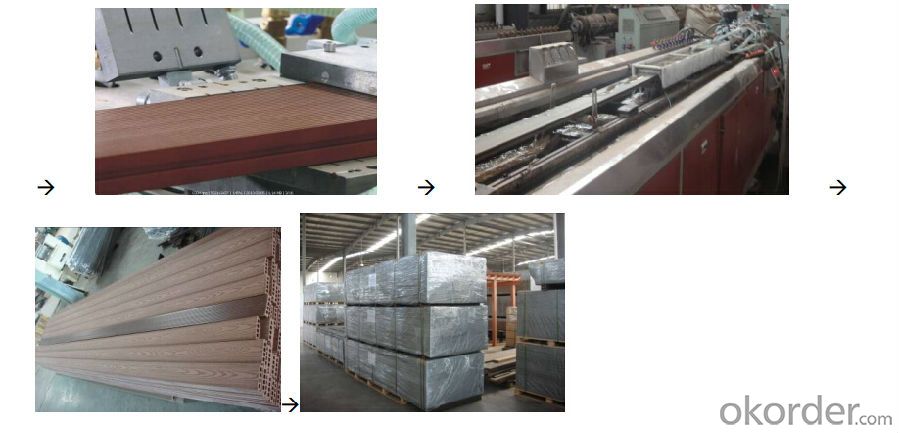

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

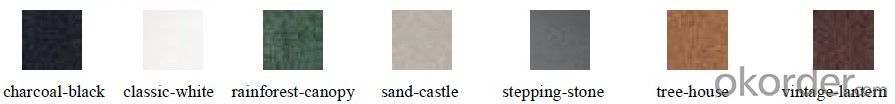

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

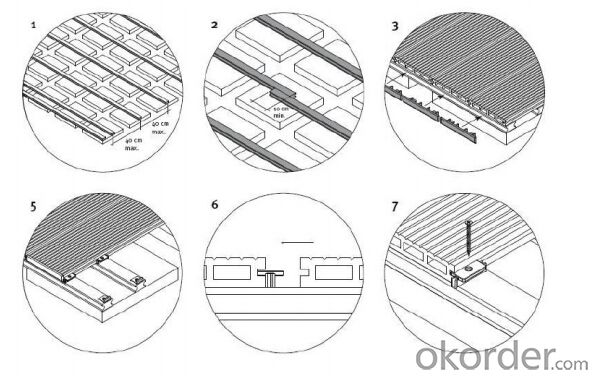

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q: How I can I simplify the floor function; insted of using the special floor markers or function (e.g. floor (f(x)) I can express x without the use of the special loor marker or function.

- Can you use the max function? If so then F(x)=max(f(x),a) (where a is the floor value) should do the job

- Q: Which would benefit you the most while doing dumbbell chest presses? laying on the floor and doing the chest press or using a bench to do the dumbbell chest press.

- floor presses isolate the inner pectoral and shoulder and uses include toning. bench presses (more common) allow the entire pectoral to strengthen with more travel for your arms to go. Incidently floor presses are not advised as practical for minor fibromayalgia occurances.

- Q: Hi I was just wondering if anyone knows of a good way to clean Laminate floors without smears. Thanks. x

- I can only tell you how I do mine, I use Mr. clean lemon scent and a micro fiber flat mop. I wash the whole floor and them rinse the mop head real well and then again go over the floor with clean warm water. That's it.

- Q: how to start add a second floor

- the only subject your going to have is on the wall which you have the two storage doorways(assuming they're on the comparable wall). you will possibly could carry out a little bracing there to span the burden of the extra height, like some engineered trusses, or something of the like. extra effective than possibly you in all probability purely have the two doubled 2x10's or tripled 2x8's as headers over the doorways correct now. all the different all and sundry is properly suited on checking with a close-by contractor approximately interior sight codes. have you ever seen only getting the truss rafters that permit for an extra room to be inbuilt them? you does no longer have as lots area, besides the undeniable fact that it would get the activity performed and you're extra effective than possibly unlikely to could do any important changes on your partitions or upload a help.

- Q: thank u very much but sorry just wondering if wooden flooring would make a difference to the warmth of the floor

- laminted flooring is a little cold but it look just as good as wood flooring and its probably cheaper than wood flooring to get it laid down it also last a long time my dad installed lamanete flooring lyk 5 yrs ago and it still looks good no chips or anything and many ppl wouldnt be able to tell the deference my aunts and uncles think we have real wood flooring and they come over my house lyk every 2 weeks so....i hope i helped

- Q: We are fixing up a small house and need some ideas that aren't too costly for concrete floors. They have been sealed before and painted a medium gray color, but we were thinking hardware floors or another alternative. Any ideas of something we can do ourselves and still look professional?

- Hardwood floors are great for living areas, but I prefer vinyl flooring for kitchens and baths. Sure tile looks great, but it's also very cold on a concrete slab house. Vinyl is also less expensive. If the house is really small, opt for carpet in the living areas. You can get some great inexpensive remants in small sizes and it makes it cozy and is still professional. I think hardwood floors are going to be trending out here shortly anyway.

- Q: The flat above mine has squeaky floors and it is, at times, unbearable. The problem is that the floors are 'floating floors' and they haven't been laid properly. My flats are 5 years old and I have a 10 year warranty, although the builder says the floors only have a 2 year warranty. Can anyone shine light on this situation??

- a friend has an old house with a same problem, he actually fixed it by filling the cracks with baby powder as what all the experts say maybe true, but ultimately the floors sqeeks where the board are joined May not work in newer houses, but for the price i'd give it a try

- Q: Multi-layer solid wood flooring paved, there part of the joint parts have relatively large gap, has three winter, and what reason? I bought the floor of life. More

- Wet wet shrinkage reasons, buy a humidifier

- Q: I am considering pulling up my carpet and painting the cement. I do not like the carpet, but I would not mind hard woods, but that is a little too much money. I have also thought of tiling the floors. How hard is it to pull the carpet up, ready the cement, and eventually paint the floor? How much money will I be needing? Suggestions please!

- Stained concrete and clear sealer can look very nice. Painting is also an option. Just be sure the product you use is specifically for concrete floors and read the direction carefully. The main thing is to have a clean surface with no dust and dirt. If you just use regular wall paint you will be in trouble.

- Q: The new house has just finished the renovation did not stay, take care of each other on the rough Nao stubs of the Association of Mao air to the water pipe off the water leakage, soak for two days only to find the water from the inside to insert the inside of the tube into the tube, the ground to plug out When there is water out, this situation on the future there is no security risks, whether the water inside the pipe to dry, how to do specific methods to solve more

- If it is wood flooring, then you tragedy, if it is tiles, then, do not have to worry about. First of all, the tile is a waterproof effect, after all, is the porcelain of Kazakhstan, there are only a little gap between the tiles and tiles, this is the cement, the time to sing may be the water, but never water, a little bit of water, even if Infiltrated into the wire tube there, there are wire tube is plastic, can be waterproof. So do not worry, do not bother. Second, the wooden floor or composite wood flooring, then the need to change the part of the whole tide, or expansion of the very powerful, tube buried in the cement, and do not have to worry about security issues, as long as the wood floor for the like The.

Send your message to us

Waterproof Enviromently-Friendly WPC Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches