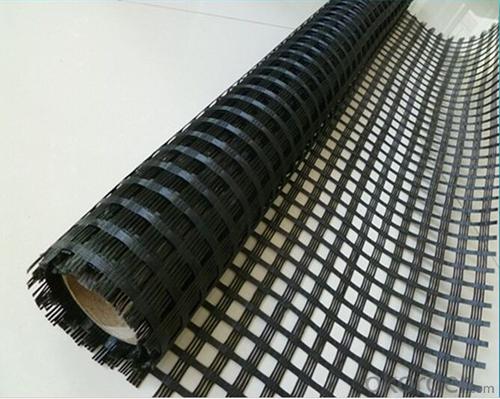

Uniaxial PVC Coated Polyester Geogrid Warp Knitting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geogrids | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX

|

Model Number: | polyester geogrid | Material: | Polyester | note: | plastic geogrid |

tensile strength: | 15,20,25,30,40,50,60,70,80,90,100,110,120 and so on | mesh size: | 36mm*36mm | roll size: | 3.95*100m or 3.95*50m |

certificate: | CE ISO |

Packaging & Delivery

Packaging Details: | plastic geogrid packing in roll or customized |

Delivery Detail: | 5 days |

Reinforcement Polyester Geogrid :

(Warp Knitted Polyester Geogrid) :

Size | PET30/30--PET400/400; PET40/30--PET600/30 |

Price:FOB QINGDAO PORT | USD 0.3/Sq.m -- 5.0/Sq.m (LARGER QUANTITY WITH NICE PRICE) |

Packing in Roll

|

Roll width 3.95 Meter, 168 rolls in one 40HC Container.

|

Tensile strength at break | 30kn~600kn |

Stretching ratio | 13% |

Grid size | 12.7*12.7mm, 25.4*25.4mm, 50.8*50.8mm |

Mesh size | 9*9mm, 20*20mm, 35*35mm |

Roll width | 1.5m, 2m,3m,3.95m,5.8m |

Roll length | 50m, 100m |

Coating | PVC |

40HC container: | about 20000 Sq.m --50000 Sq.m |

Customize: | You can get more than what you pay for. Min 10000Sq.m |

Place of Origin | SHANDONG DAGENG, TAIAN CITY, SHANDONG, CHINA. |

Certificate | ISO ,CE |

FAQ

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C , Western Union,Paypal ...

3. What’s your delivery method ?

By sea , By train , etc

4. What's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable

- Q: Are geogrids suitable for use in saline environments?

- Yes, geogrids are suitable for use in saline environments. Geogrids are typically made of high-strength polymers that are resistant to corrosion and degradation caused by saline environments. Additionally, they have been extensively used in coastal and marine engineering projects where they are exposed to saltwater and have shown excellent performance and durability. Therefore, geogrids can be a reliable and effective solution for reinforcing soil structures in saline environments.

- Q: Are geogrids suitable for use in ground reinforcement for wind farms?

- Yes, geogrids are suitable for use in ground reinforcement for wind farms. Geogrids provide excellent soil stabilization and reinforcement, which is crucial for supporting the heavy equipment and structures associated with wind farms. They distribute loads evenly, increase bearing capacity, and prevent soil erosion, making them an ideal choice for enhancing the stability and longevity of wind farm installations.

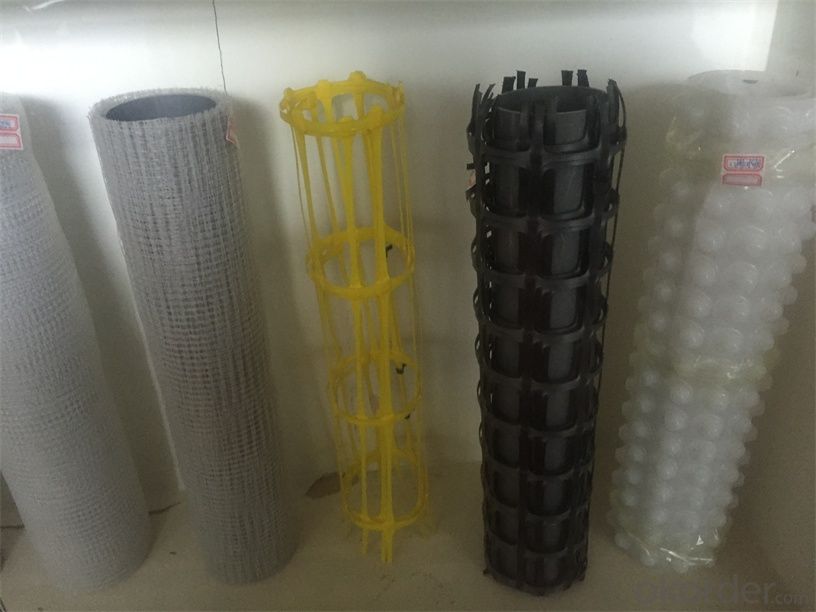

- Q: What are the types of Geogrid

- There are many types of geogrid is about tgsg / convex node tgsg / whole tgsg / glass fiber geogrid

- Q: Is there any difference between glass fiber grille and geogrid

- Geogrid also includes polyester grille, steel plastic grille, plastic grille, etc.!

- Q: What are the advantages of using geogrids over traditional reinforcement methods?

- Geogrids offer several advantages over traditional reinforcement methods. Firstly, geogrids are lightweight and easy to install, reducing labor and transportation costs. Secondly, geogrids have high tensile strength, providing excellent soil stabilization and reinforcement. Additionally, geogrids are highly resistant to chemical and biological degradation, ensuring long-term durability. Lastly, geogrids are flexible and adaptable to varying soil conditions, making them suitable for a wide range of applications, including road and slope stabilization, retaining walls, and erosion control.

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can affect the installation and survivability of geogrids in harsh environments. Firstly, the type and quality of the geogrid material plays a crucial role. Geogrids made from high-strength polymers or synthetic fibers are more likely to withstand extreme conditions. Secondly, the design and installation techniques used are important factors. Proper anchoring, tensioning, and overlap of geogrids can enhance their durability in harsh environments. Additionally, the soil type and its characteristics, such as cohesion and friction angle, can impact the performance of geogrids. The presence of aggressive chemicals, temperature fluctuations, and exposure to UV radiation are other factors that can affect their survivability. Overall, a thorough understanding of these factors and adherence to best practices during installation are essential for ensuring the successful functioning of geogrids in harsh environments.

- Q: Can geogrids withstand heavy loads?

- Yes, geogrids are specifically designed to withstand heavy loads and provide stability to the soil. They are made from high-strength materials such as polyester or polypropylene, which have excellent load-bearing capacity. Geogrids are commonly used in civil engineering projects, road construction, and retaining walls to reinforce soil and distribute the load more evenly, thereby enhancing the overall strength and durability of the structure.

- Q: Refers to the size of the geogrid mesh holeSpecific attention is not clear, the banner of Chang Chang official CafeThere's something you're looking forGrille generally by the vertical and horizontal staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Refers to the size of the geogrid mesh holeSpecific attention is not clear, the banner of Chang Chang official CafeThere's something you're looking forGrille generally by the vertical and horizontal staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Q: What are the limitations of using geogrids?

- Geogrids have certain limitations that need to be considered. First, they are not suitable for all soil types and conditions, as they may not provide sufficient reinforcement or stability in certain situations. Additionally, geogrids are not effective in controlling erosion or preventing soil movement on their own; they need to be combined with other erosion control measures. Furthermore, installation and maintenance of geogrids can be complex and require expertise, making them more expensive compared to traditional soil stabilization methods. Finally, geogrids have a limited lifespan and may degrade over time, requiring replacement or repair.

- Q: Can geogrids be used in temporary construction haul roads for mining applications?

- Yes, geogrids can be used in temporary construction haul roads for mining applications. Geogrids are a type of geosynthetic material that can provide stabilization and reinforcement to the road base, increasing its load-bearing capacity and reducing the risk of erosion and rutting. They are commonly used in mining applications to improve the performance and longevity of haul roads, even in temporary construction scenarios.

Send your message to us

Uniaxial PVC Coated Polyester Geogrid Warp Knitting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords