Underlay Membrane Water resistant and Vapor breathable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Breathable Membrane PP Non-woven Fabric Laminated with PE Film

General Information:

We are located in National Development Zone in Nantong, with 22000 square meters area, including 7000 square meters dust free workshop.

We have equipped the most advanced pp non-woven production line and composite production lines including extrusion lamination production, hot melt lamination production line, calendar bonded production line with the technology from Italy and Germany, printing production line, cutting production line. We specialize in producing waterproof and breathable materials and heat insulation materials, pp non-woven fabric, disposable medical products, packaging materials and so on.

Specifications:

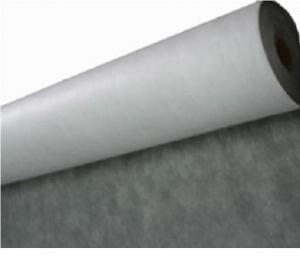

Product Name | Composite PP Non-Woven Roofing Breathable Waterproof Membrane |

Color | Grey |

Structure | PP Non-Woven/PE Film/PP Non-Woven |

Roll Width(m) | 1.5m (+/-0.5%) |

Roll Length(m) | (1)50m,100m,200m,500m,1000m (2)according to the customers' requirements |

Basic Weight | 80g/m²,90g/m²,100g/m²,115g/m² ,120g/m² ,140g/m² ,160g/m² |

Temperature Resistance | -40 °C to 100 °C |

Water Resistant | Class 1 |

SD-Value | 0.02m |

Vapor Permeability | 2250g/m²/24h |

UV Resistant | 3-6 months |

Packing | 1)each roll packed by plastic bag, then with carton or pallets 2)according to the customers' request |

Price Terms | FOB,CNF,CIF |

Payment Terms | TT,LC, |

Delivery Time | within 15 working days after received your payment in advance |

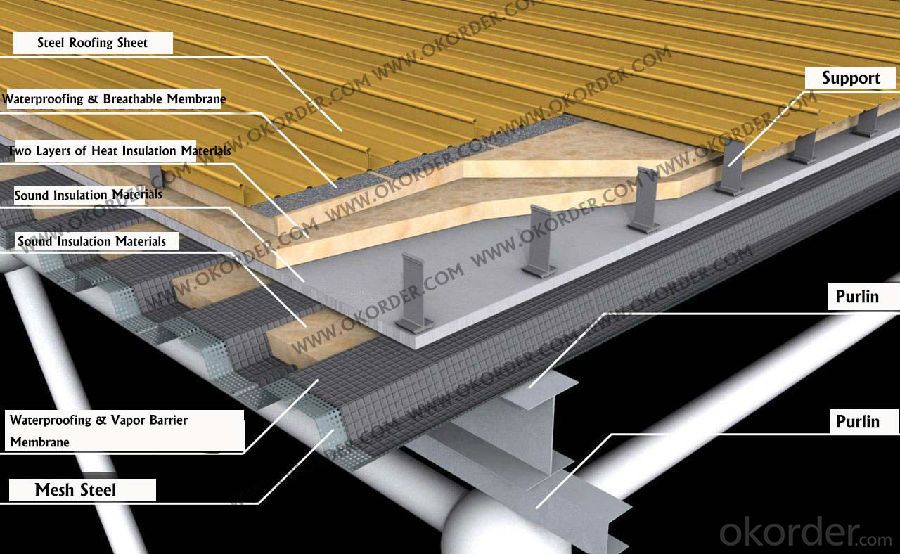

Typical Application:

Container Loading:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- It is best not to drill in the finished product on the screen, if it is absolutely last resort, You can use fiberglass material in the hole position paper;

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- Do the cabinet can be in accordance with your size, finished cabinet moldy, which is not necessarily. You have to buy some of the Well

- Q: What is the price of a waterproof window cover?

- 1, solid wood sets With the emphasis on environmental protection and economic conditions, some families choose solid window curtains, solid wood materials with environmental protection, beautiful, natural and other advantages, but also easy to deformation, thermal expansion and contraction, crack and other shortcomings. According to the final color of different, solid wood sets are divided into primary colors, color and color mixing. At present, more often solid wood materials are Pinus sylvestris, red pine, Qu Liu, Catalpa wood, and some valuable materials such as: beech, Phoebe, pear, rosewood and so on.

- Q: Oriental rain rain waterproof how to

- Strict selection and the pursuit of excellence in product performance of the East Rainbow waterproof coating long-term waterproof material in the market leading the main reason. In order to test product performance, the East Rainbow company to the product to the plateau, desert, alpine, high temperature and other areas for testing.

- Q: Can Henkel have water against him?

- Can ah ~ watered effect on the discount friends are high with the general are good, powder + pulp! Do not need to add water

- Q: How does the finished ventilator manufacturer waterproof?

- do not play any silicone and tape, to avoid the silicone tape aging caused by leakage hazards. Can be done once and for all.

- Q: FRP finished brush on what can be waterproof do not fade

- With glass fiber reinforced plastic + color paste even after the use of. Can be waterproof.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Second, the completion of the construction of the membrane and the acceptance of qualified, should do the protection of finished products, it is recommended to use cement mortar to do protective layer, construction should pay attention to the surface should be smooth pressure, and set the surface sub-grid, 1 m2. If the use of block material to do the protective layer, the sub-grid area should not be greater than 100 square meters, sub-grid width should not be less than 20mm; if the use of fine stone concrete protective layer, the sub-grid area should not be greater than 36 square meters. Note: Regardless of which protective layer is used, a separation layer should be provided between the waterproofing layer and the protective layer.

- Q: How does the waterproofing membrane work?

- 5, lap seam treatment: the roll is rolled, the adjacent two webs of the joints with a short stove welding welding sticky, heated to spill hot melt adhesive for the degree, and then use the flame and iron wipe The sub-joints will be evenly heated to wipe the edge; 6, the coil side of the sealing side of the construction.

- Q: Waterproof material water leakage construction should pay attention to what

- 3, do the closed water test After the waterproof construction is completed, the water storage test. Will be blocked all the toilet outlet, the door at a pound of about 200mm high barrier, and then poured in the bathroom about 20mm ~ 30mm deep water, and 24 hours after the inspection of the walls and the ground around the leakage phenomenon , Waterproof test is to ensure the quality of the bathroom waterproofing the key, we must do. Such as after 24 hours without leakage as qualified. If you find a leak, you should immediately stop the water storage test, re-waterproof layer to improve the treatment, after passing the water test.

Send your message to us

Underlay Membrane Water resistant and Vapor breathable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches