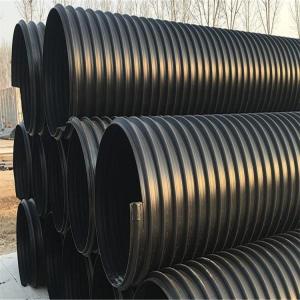

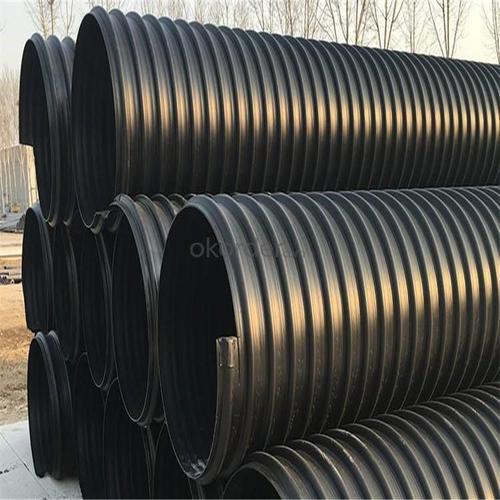

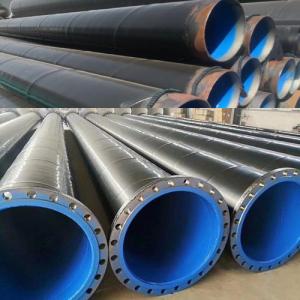

Underground Metal Reinforced PE Spiral Corrugated Pipe for Drainage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Metal Reinforced PE Spiral Corrugated Pipe for Drainage

Press grade: SN8/SN10/SN12.5/SN16

Size: DN300MM-DN1800MM

Standards:

Features:

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: How are steel pipes tested for mechanical strength?

- Steel pipes are typically tested for mechanical strength through various destructive and non-destructive testing methods. Destructive tests involve subjecting the pipes to tension, compression, or bending forces until failure occurs, allowing the measurement of their ultimate tensile strength, yield strength, and elongation. Non-destructive tests, such as ultrasonic testing, magnetic particle inspection, or radiographic examination, are also conducted to detect any internal or surface defects that may affect the mechanical strength of the pipes. These tests ensure that steel pipes meet the required standards and specifications in terms of their mechanical strength.

- Q: What is the difference between steel pipes and plastic pipes?

- The main difference between steel pipes and plastic pipes lies in their material composition. Steel pipes are made from a durable and strong metal alloy, while plastic pipes are composed of various types of plastic polymers. This difference in materials leads to variations in their properties and usage. Steel pipes are known for their high strength, resistance to extreme temperatures and pressures, and longevity, making them suitable for applications requiring robustness, such as in industrial settings or underground pipelines. On the other hand, plastic pipes are lightweight, flexible, and corrosion-resistant, making them ideal for plumbing, irrigation, and other non-industrial applications. Additionally, plastic pipes are easier to install and handle due to their lighter weight and flexibility compared to steel pipes.

- Q: What are the different types of steel pipe connections for steam pipelines?

- There are several types of steel pipe connections commonly used for steam pipelines. These include threaded connections, flanged connections, welded connections, and grooved connections. Each type has its own advantages and is chosen based on factors such as the pipe size, pressure, and temperature requirements, as well as the ease of installation and maintenance.

- Q: Theoretical weight of 25*25*1.5 square steel tubes

- Square steel tube, referred to as square tube, also known as square tube, is a square pipe of a kind of name, that is, the length of the same steel pipe. The strip is rolled by process. Generally, the strip is disassembled, leveled, crimped and welded to form a round tube. The tube is then rolled into square tubes and cut to the required length, usually 50 pieces per package.

- Q: What are the common standards for manufacturing steel pipes?

- The common standards for manufacturing steel pipes include the American Society for Testing and Materials (ASTM) standards, the International Organization for Standardization (ISO) standards, and the American National Standards Institute (ANSI) standards. These standards cover various aspects such as material composition, mechanical properties, dimensions, testing procedures, and quality control requirements to ensure the consistency and reliability of steel pipes.

- Q: Which is cheaper, angle iron or steel pipe?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. Also available models that model is the number of centimeters wide, such as angle 3#.

- Q: How are steel pipes used in underground drainage systems?

- Steel pipes are commonly used in underground drainage systems due to their durability and strength. They are used to transport wastewater, stormwater, and other liquids away from buildings and infrastructure to a designated discharge point. The steel pipes provide a reliable and long-lasting solution, ensuring the efficient flow of water and preventing any potential leaks or damage to the surrounding environment.

- Q: What are the factors affecting the lifespan of steel pipes?

- The lifespan of steel pipes can be influenced by several factors. 1. Corrosion is a primary factor that can considerably diminish the lifespan of steel pipes. Over time, exposure to moisture, chemicals, and other corrosive elements can result in rusting and degradation of the pipe material. 2. The environment in which the steel pipes are installed plays a vital role in their longevity. Extreme temperatures, humidity, and exposure to various weather conditions can expedite the corrosion process and weaken the pipe structure. 3. The quality of the water flowing through the steel pipes can also affect their lifespan. Water with high levels of acidity or alkalinity, excessive chlorine, or other contaminants can cause corrosion and deterioration of the pipe material. 4. The way steel pipes are installed can impact their lifespan. Poor installation practices, such as inadequate support or incorrect alignment, can create stress points and structural weaknesses, making the pipes more susceptible to failure. 5. Regular maintenance and timely repairs are crucial for maximizing the lifespan of steel pipes. Proper cleaning, inspection, and corrosion protection measures can help identify and address potential issues before they escalate and cause significant damage. 6. The design and quality of steel used in pipe manufacturing are important factors in determining their lifespan. High-quality steel with appropriate alloy composition and thickness provides better resistance to corrosion and mechanical stress, ensuring a longer lifespan. 7. The durability of steel pipes can be influenced by the load and pressure they are subjected to. Excessive pressure or frequent variations in pressure can stress the pipe walls, leading to fatigue or failure over time. By considering and addressing these factors, it is possible to extend the lifespan of steel pipes and ensure their reliable performance over an extended period of time.

- Q: What are the different types of valves used with steel pipes?

- There are several types of valves commonly used with steel pipes, including ball valves, gate valves, globe valves, check valves, and butterfly valves. These valves serve different purposes and have various designs, such as quarter-turn operation for ball valves, wedge-shaped gates for gate valves, and disc-shaped elements for butterfly valves. Each type of valve offers specific advantages and is selected based on the application requirements and the flow control needs of the steel pipe system.

- Q: There are multiple welded galvanized steel pipe outer diameter 108mm wall thickness 4mm length of 6 meters

- Galvanized steel pipe wall thickness weight outer diameter 108mm 4mm 6 meters in length is about 10.26*6*1.06=65 kg.Kg/m= (outside diameter mm-, wall thickness mm) * wall thickness mm*0.02466= (108-4) *4*0.02466=10.26 kg / MBecause of galvanizing, the weight is heavier than that of ordinary welded pipe 3%~6%.

Send your message to us

Underground Metal Reinforced PE Spiral Corrugated Pipe for Drainage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords