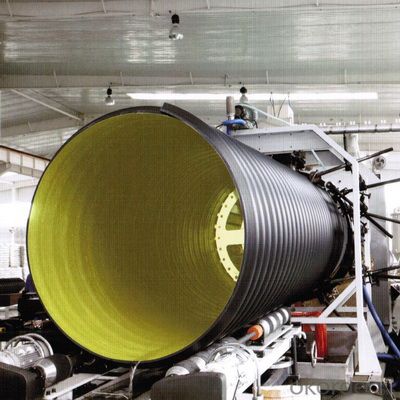

large diameter steel reinforced corrugated polyethylene pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel reinforced corrugated polyethylene pipe is a new kind of corrugate pipe taken HDPE as body with parietal layer spirally wound and hollow rib reinforced by lining steel strips. SSRCSP owns unparallel advantages compared with traditional metal and concrete pipes,owing to the adoption of ring hollow structure wond with reinforcement made of steel strips, it owns the characteristics of high ring stiffness(8~16 Kn/m2),high strength and toughness,high pressure resistance and anti.sedimentation, light weight, impact and water sourcing resistance, high quake and freeze proof, breakage and leakage resistance, easy installation,long service life (50 years under normal usage conditions)and non-secondary pollution etc, besides the common characteristics of corrosion resistance, smooth wall and small flow resistance etc as the ordinary plastic pipes own, therefore, it’s widely used drainage, sewage, agricultural irrigation, mine ventilation, chemicals, telecommunications cablesheathing and other fields.Owing to light weight and safe and convenient transport and installation without using large equipments,it could reduce the labor intensity of contruction personnel and decrease the construction investment and it is the ideal replacement of Concrete pipe and ordinary plastic pipe.

Steel Reinforced Corrugated Polyethylene Pipe Characteristics:

1.High corrosion resistance and acid and alkali-resistance;

2.High ring stiffness,light weight and easy installation and construction;

3.High reliablity owing to seamless connection between inner wall bymeltingplastic;

4.Various connections could be choosed, simple and easy operation.

Physical Properties Table of Steel Reinforced Corrugated Polyethylene Pipe

| Items | Index | Test method | |

| Ring stiffness | SN8 | ≥8 | GB/T9674-2003 |

| SN12.5 | ≥12.5 | ||

| SN16 | ≥16 | ||

| Impact properties | TIR≤10% | GB/T14152 | |

| Peel strength(20°C±5°C)/N/cm | ≥70 | ||

| The ring flexibility | No rupture, no wall off | GB/T9647 | |

| Oven test | No stratification, no cracking | ||

| Tensile strength(N) of Polyethlene Connection Interface | ≥1460 | GN/T8804 | |

| Creep rate | ≤2 | GB/T18042 | |

Steel Reinforced Corrugated Polyethylene Pipe Sizes and Specification:

Norminal Ring Stiffness: SN4 SN8 SN12.5

Sizes: DN500mm-DN2200mm

| DN/ID | Average min inner diameter (dim.min) | The minimum thickness (emin) |

| 300 | 294 | 2.5 |

| 400 | 392 | 3 |

| 500 | 490 | 5 |

| 600 | 588 | 6 |

| 700 | 673 | 6 |

| 800 | 785 | 6.5 |

| 900 | 885 | 7 |

| 1000 | 985 | 7 |

| 1100 | 1085 | 7 |

| 1200 | 1185 | 7 |

| 1300 | 1285 | 7 |

| 1400 | 1385 | 7 |

| 1500 | 1485 | 7 |

| 1600 | 1585 | 7 |

| 1800 | 1785 | 7 |

| 2000 | 1985 | 8 |

| 2200 | 2185 | 8 |

Steel Reinforced Corrugated Polyethylene Pipe Fields of Application:

1.Agricultural Irrigation: used as deep-well pipe, strainer pipe,culvert pipe, drainage pipe or irrigation pipe etc.

2.Municipal Engineering: blow-off line,fire fighting pipeline,water supply, backwater, natural gas pipeline, etc.

3.Chemical Engineering: Discharge pipeline for corrosive gases, liquid, dust in industries of Acid, Alkali, salt manufacturing , Petro-chemical, chemical fertilizer, pharmaceutical, plastic, etc.

4.Oil-gas Field: pipeline for gathering oily sewage, gas-oil mixture, as well as secondary and tertiary oil recovery.

5.Thermal-electricity Engineering: pipeline for industrial water supply, backwater, conveyance of industrial waste residue, etc.

6.Metallurgy and mine: conveyance of corrosive medium, mining pulp, tailing and waste water during ferroalloy smelting; pipeline of conveying Coal Methane and water.

7.Highway construction: drainpipe and cable duct tube.

8.Ocean engineering: conveyance of sea water, offshore pipeline, cable/ optical cable duct tube.

9.Shipbuilding: ship pipeline, ballasting pipe, vent-pipe.

- Q: How are plastic tubes tested for quality and safety?

- Plastic tubes are tested for quality and safety through a series of rigorous evaluations. These evaluations typically include tests for physical properties such as tensile strength, flexibility, and durability. Additionally, they undergo assessments for chemical and biological safety, ensuring that they are free from harmful substances and do not pose any health risks. These tests can involve conducting chemical analyses, assessing stability under various temperature and pressure conditions, and examining the tubes for potential leaching or degradation. Overall, these comprehensive testing procedures ensure that plastic tubes meet industry standards and are safe for their intended use.

- Q: The point is to remove as many sticks as you can without the marbles falling through.Anyone know? Thanks :)

- Yea kerpluck. good game man good game

- Q: Can plastic tubes be used for packaging liquids?

- Yes, plastic tubes can be used for packaging liquids. They are commonly used for products such as lotions, creams, gels, and other liquid-based substances. They provide a convenient and efficient way to dispense and store liquids while ensuring product integrity and ease of use.

- Q: there is a plastic tube that goes from the bathroom sink(strainer) into the wall. It seems to be clogged. How do I go about fixing this if it is leaking?

- It should be about an inch and a quarter in diameter. At the wall there is what looks like a big nut. Take a large pliers and turn counterclockwise and take it loose. Take your hand, touch that nut and go back wards toward the sink and you will find another. Take that one off too, counterclockwise. Be sure to have a small bucket under the sink since you will loose some water. Take the plastic piece to the hardware store, buy new gaskets with it and put it back on. Do not over tighten,

- Q: I have a pond pump and standard aquarium plastic tubing. I will be drilling tiny holes in equal increments throughout the tubing to release the air. Is there an equation to show the air pressure that will be released through the holes? I would like to know how many holes I need and how far to space them to achieve a certain amount of air pressure to be released from a specified length of tubing.This is a test and will not be done under water. A simple diffuser will not work for this application.Ideally I would like a formula where I can input the following and get a result:Tube LengthTube DiameterPump PSITube Hole SizeTube Hole QuantityTube Hole SpacingResultAirflow per Tube HoleAny help would be greatly appreciated. If you need more information please let me know.Thank you,

- Well, I suppose it could be done, but you would need the pressure at each hole,which is decreasing as the tube length and water depth. And you have so many variables! I also like to calculate such things as you are doing, but this is really over the top! Here is what I would do; Get a measured paper cup (say 1 cup, or 1/4 litre). Experiment with various sizes and number of holes in your tubing, then hold the cup over the coiled tubing, under water at required depth, with air pump running. Measure the time to fill the inverted cup with air. If a 1/4 litre container fills with air in 15 seconds (1/4 minute), you know you are getting 1 litre per minute. Then try other hole configurations to get what you want. This would be more fun, more practical, and will give bettter results. Good luck Bill

- Q: What are the common lengths of plastic tubes used for interior design?

- The common lengths of plastic tubes used for interior design vary depending on the specific application and project requirements. However, typical lengths range from 1 foot (30 centimeters) to 8 feet (240 centimeters).

- Q: I live in Mississauga, and I was wondering if there were any places close by even in Toronto that sell neon plastic test tubes, for drinking purposes/partying. Would the dollar store provide that sort of stuff, or do I have to order that online?

- www.okorder

- Q: Are plastic tubes resistant to warping under high temperatures?

- No, plastic tubes are not typically resistant to warping under high temperatures.

- Q: Fly fishing question, I am taking up the hobby :)

- if you are talking about tying your own anglers workshop online has many materials to choose from.

- Q: How does transferring of liquid in a container to an empty container using a plastic tube works?

- A siphon hose used to draw gas from a car's fuel tank is one example and is a very simple pump. Sucking on one end of the hose creates an area of low pressure compared to the relatively high-pressure area of the gas tank. This low pressure versus a higher pressure is key to the transfer. Eventually, the gasoline will come out of the low-pressure end of the hose and the process feeds on itself so to speak via momentum, and the fluid continues to transfer.

Send your message to us

large diameter steel reinforced corrugated polyethylene pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords