Galvanized welded steel pipe for materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1、Structure of Galvanized welded steel pipe for materials :

The surface of galvanized steel pipe welded steel pipe of hot dip galvanized layer or. Galvanized can increase the corrosion resistance of the steel tube, prolong service life. Galvanized pipe is widely used, in addition to water, gas, oil and other general low pressure fluid pipelines. It is also used in the petroleum industry, especially for offshore oil field of oil well pipe and oil pipe, chemical, coking equipment of oil heater, condensation cooler, coal run oil exchanger tube, and trestle pile, the mine tunnel support frame tube.

2、Main Features of Galvanized welded steel pipe for building materials :

• High manufacturing accuracy

• High strength

• Good visual effect

• Reasonable price

3、 Galvanized welded steel pipe for building materials Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1 - 33 mm |

Section Shape | Round |

Outer Diameter | 21 - 610mm |

Place of Origin | Tianjin, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:Q195 Q235 Q345 X42 X52

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Galvanized welded steel pipe for building materials :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

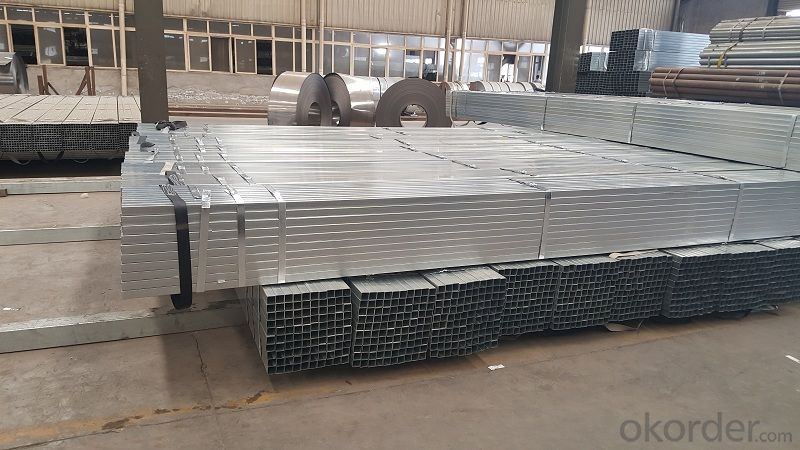

6、 Galvanized welded steel pipe for building materials Images:

- Q: What is the maximum temperature that steel pipes can withstand?

- The maximum temperature that steel pipes can withstand depends on the grade and type of steel used. Generally, carbon steel pipes can withstand temperatures up to 1000°C (1832°F), while stainless steel pipes can handle temperatures up to 1200°C (2192°F). However, it is essential to consult the specific specifications and guidelines provided by the manufacturer for accurate temperature limits.

- Q: What is the minimum temperature that steel pipes can handle?

- The minimum temperature at which steel pipes can withstand depends on the particular grade and composition of the steel. In general, steel pipes can endure extremely low temperatures without encountering significant issues. In fact, numerous steel varieties are specifically engineered to endure freezing temperatures, making them suitable for a range of uses in industries like oil and gas, construction, and cryogenics. However, it is crucial to acknowledge that steel may become more brittle at exceedingly low temperatures, which can impact its mechanical properties. Therefore, it is vital to meticulously choose the appropriate steel grade and consider any specific requirements or limitations for the desired application when determining the minimum temperature that steel pipes can handle.

- Q: How are steel pipes coated for insulation purposes?

- Various methods and materials are commonly used to coat steel pipes for insulation. One method involves applying a thermal insulation coating, typically made of a high-performance polymer or epoxy-based material, to the surface of the pipe. To ensure proper adhesion of the coating, the steel pipe is first thoroughly cleaned to remove dirt, grease, and rust. This cleaning process, known as abrasive blasting, involves propelling small particles at high speed to remove contaminants and create a clean, rough surface. Once the surface is prepared, the thermal insulation coating is applied using techniques such as spraying, brushing, or rolling. Multiple layers of the coating are carefully applied to ensure adequate coverage and thickness. This forms a protective barrier between the steel pipe and the external environment, preventing heat transfer and reducing energy loss. In addition to thermal insulation coatings, steel pipes can also be coated with materials like polyurethane foam or mineral wool. These materials offer excellent thermal insulation properties and are often used in applications where high-temperature resistance is necessary. Overall, the insulation of steel pipes involves a combination of surface preparation and the application of specialized coatings. These coatings serve to minimize heat loss, improve energy efficiency, and protect against corrosion and other environmental factors.

- Q: Can steel pipes be used for underground sewerage systems?

- Yes, steel pipes can be used for underground sewerage systems. Steel pipes are strong and durable, making them suitable for carrying sewage underground. They have a high resistance to corrosion and can withstand the pressure and load of the ground above. Steel pipes also have a long lifespan and are resistant to environmental factors such as moisture, chemicals, and temperature fluctuations. Additionally, steel pipes can be easily welded, making installation and repairs more convenient. However, it is important to ensure that the steel pipes are properly coated or lined to prevent corrosion and to comply with local regulations and standards for underground sewerage systems.

- Q: How are steel pipes used in the manufacturing of bicycles?

- Steel pipes are commonly used in the manufacturing of bicycles as they provide strength, durability, and flexibility. They are used to create the frame, handlebars, and other structural components of the bike. The steel pipes are cut, shaped, and welded together to form the frame, providing a sturdy and reliable structure for the bicycle.

- Q: Seamless steel pipe is how to do it?

- Probably with 10, 20, 30, 35, 45 and other high-quality carbon steel, 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other composite steel hot-rolled or cold rolled.

- Q: How can galvanized steel pipe be connected with stainless steel pipe?

- Attention should be paid to the zinc coating at the side of the groove before welding. It is OK to brush silver powder after welding. There is a lot of information about the welding of carbon steel and stainless steel. Just check it online.

- Q: How are steel pipes used in heating systems?

- Steel pipes are commonly used in heating systems to transport hot water or steam from the boiler to various heating devices, such as radiators or baseboard heaters. The steel pipes are durable and can withstand high temperatures and pressure, ensuring efficient and safe distribution of heat throughout the building.

- Q: What place must use galvanized steel pipe to make lighting line?

- Galvanized pipe for pipeline laying construction and transformation of lighting, power, telephone, fire protection system in the engineering (made of galvanized steel), for laying, laying can be laid in the dark, the wall can also be installed on the ceiling.

- Q: How are steel pipes protected against internal scaling?

- Internal coating or lining is a process employed to safeguard steel pipes from internal scaling. This entails applying a protective layer on the inside of the pipe to prevent the formation of scales or deposits. Multiple techniques are utilized for this purpose. One prevalent approach is the application of epoxy coatings. Epoxy, a resilient and corrosion-resistant material, forms a continuous barrier on the pipe's interior. It effectively hinders the accumulation of minerals and other substances that contribute to scaling. Epoxy coatings are commonly sprayed or brushed onto the inner surface of the pipe and then hardened to create a durable and smooth finish. Cement mortar lining is another method used to protect steel pipes from internal scaling. This involves applying a layer of cement mortar to the pipe's interior. The cement mortar acts as a barrier against scaling and offers additional corrosion protection. This lining process is typically employed for large-diameter pipes utilized in water distribution systems. Polyethylene (PE) lining is yet another technique deployed to safeguard steel pipes against internal scaling. PE lining necessitates the insertion of a high-density polyethylene liner into the pipe. This liner acts as a barrier against scaling and enhances fluid flow by reducing friction. PE lining is frequently used in applications that require a smooth interior surface, such as oil and gas pipelines. Apart from these methods, regular maintenance and cleaning of the pipes can also aid in preventing internal scaling. This may involve using chemical cleaning agents or mechanical cleaning techniques to eliminate any deposits that have formed on the pipe's interior surface. Overall, safeguarding steel pipes against internal scaling is vital to maintain their efficiency and prolong their lifespan. By employing various coating and lining methods, along with implementing appropriate maintenance practices, the risk of internal scaling can be significantly diminished.

Send your message to us

Galvanized welded steel pipe for materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords